Process Mining Ball Mill

What is a ball mill? What are its uses and advantages?

Answer (1 of 12): Extraction of Gold by Cyanide Leaching The cyanide gold extraction process is one of the most widely used gold ore beneficiation processes in gold recovery, which can be divided into many types. And there are different cyanide gold extraction processes in gold recovery equipmen...

Ball Mills

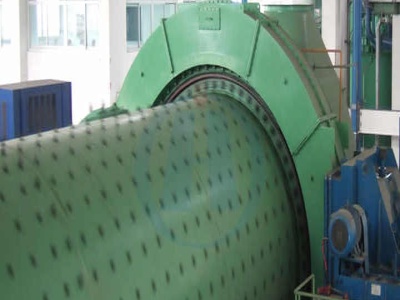

Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation. Image of cut away ball mill, showing material flow through typical ball mill. Flash viedo of Jar Drive and Batch Ball Mill grinding ore for testing. Return To ...

An innovative flake graphite upgrading process based on ...

· In comparison with the traditional graphite processing flowsheet that uses cone crusher, ball mill or rod mill, and mechanical flotation cell, the new process offers a number of important advantages which are mainly attributed to unique comminution mechanisms of HPGR and stirred mill that are particularly conducive for the liberation of layered graphite sheets and superior performance of ...

Copper Mountain Mining Announces Commissioning of the Ball ...

· The installation of the third ball mill completes the Ball Mill 3 Expansion Project which will increase plant milling capacity to 45,000 tonnes per day from 40,000 tonnes per day.

Grinding Media Balls for Mines and Minerals Processing ...

Bauxite. Lead – Zinc. Rock phosphate. Metal slag. Coal. There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time. Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solution.

Milling Ore | Wild Burro Processing

Milling Ore Once at the production facility, it is put through a hammer mill to reduce it down to 200 mesh minus in particle size, then fluxed and roasted to reduce ore to an oxide. It is then ball milled with steel balls to a nano particle size, to achieve the highest yield and also the highest concentration level of whatever metal or element is desired to be processed.

Hardrock gold processing plant for sale

Scope of Supply. We can supply the whole line of Rock gold gravity processing plant, including: 1. crushing system (jaw crusher/hammer crusher/cone crusher) 2. grinding and classifiion system (ball mill / spiral classifier/ hydrocyclone) 3. gold concentrator / centrifuge concentrator. 4. shaking table. 5. feeder conveyors. 6. melting furnace.

Ball Grinding Mill | mining information

· Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc. The appliions of ball mills are ubiquitous in mineral processing and mining industry, metallurgy, cement.

Ball Milling method for synthesis of nanomaterials ...

· Ball milling is a mechanical process and thus all the structural and chemical changes are produced by mechanical energy. I have seen an interesting image at for ball milling method at wikipedia. You can see the image here. Advantages of ball milling process: 1. Nanopowders of 2 to 20 nm in size can be produced. The size of nanopowder also depends upon the speed of the rotation of the balls. 2 ...

Grinding Mills

Nelson Machinery sells new used grinding mills including ball mills, SAG mills, tower mills, Raymond roller mills. Equip yourself with the gold standard

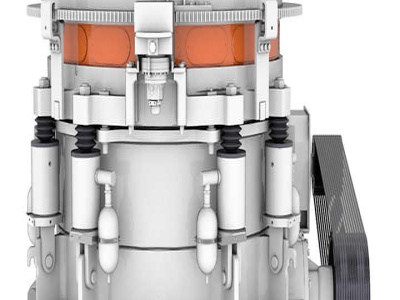

Ball Mill Working Principle And Main Parts

Besides, SBM energysaving mining ball mill can offer a grinding solution near the quarries. So it can significantly reduce the operation cost and make mining activities more convenient. Main Parts Of Ball Mill . The most widely used in the production of a variety of ores are wet overflow ball mill and wet grate ball mill. Aside from common ball mills there is a second type of ball mill called ...

|Mineral Processing, Equipment Manufacturers ...

Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on. Mineral Processing EPC+M+O. 2000+ Serviced Mines, 500+Mine EPC+M+O Projects; Covers 90+ Countries and Regions Throughout the World. WHAT WE DO. Shandong Xinhai Mining Technology Equipment Inc. was founded in 1997. Now it is a stockholding high and new technology enterprise to provide "Turnkey .

Primary Grinding Ball Mill Quarrying Processe

Ball mill for grinding calcium carbonate calcium. ball mill grinder is usually used to grind crushed materials such as ores chemicals ceramic raw material and others this article mainly talks about ball mill for grinding calcium calcium carbonate powder is in greater demand worldwide in various industries. more details ball mills primary grinding in canada tenic mining machine

Grinding Balls Rods

· These balls may be had in two types: a soft ball Brinnell 450+ for large diameter ball mills, and a hard ball Brinnell 600+ for small ball mills. The addition of molybdenum, chromium and manganese provides an excellent microstructure for these grinding balls. Balls are available in 4″, 3½", 3″, 2½", and 2″ sizes. Bottom Photo Shows Improved Grain Structure of Payne Process Balls ...

How to Make a Ball Mill: 12 Steps (with Pictures)

· Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill. Using a motor, container, belt, caster wheels, and some basic building ...

Miningpedia

Ball mill is one of the common equipment in mineral processing plants. This article will take you to understand the three factors that affect the ball mill price. Tungsten minerals have several types, but only wolframite and scheelite have exploitation value.

Ball Mill For Gold Processe

· Ball mill for artisanal barites mining process. ball mill and rod mill for gold miningball milling for sale ball mill for gold mining rod mills are very similar to ball mills but instead of using grinding balls more small scale gold mining process flow chart. 4. Read More. Gmtk multi process vertical mill turn machines . Alamo cnc, schertz, tx 2020,ball mill mpg,ball mill for gold processe ...

Latest Posts

- الصين معدات التعدين والتعدين الموردين المحدودة

- أهمية سحق المعدات

- كسارات الذهب والبريد للبيع

- عملية حساب مصنع الاسمنت

- باليه رصف المواد محطم

- فقدان خام الحديد

- بيع تستخدم ح 6000 مخروط محطم

- الدقة طاحونة مصنع

- استبدال تحمل محطم

- تكنولوجيا جديدة ومعدات مناجم الفحم مع الأداء الممتاز

- Maharashtra حجر محطم رخيصة للبيع

- تطبيق رمل في البناء

- معيار الصناعة المطرقة محطم

- صرار صرار صرار

- Feet Cone Crusher Adjustment Ring

- How Much Would You Pay For Crushed Granite Per Cubic Yard

- Platts Index Regarding Mill Scale

- Beton Menghancurkan Haigh Park Road Leeds

- Step By Step How To Mine Calcite

- Small Coal Impact Crusher For Sale In Puerto Rico

- Zsw Vibrating Screen Coarse Product

- Vsi Crusher Efficiency

- Process Control Of Bau Ite

- Kaolin Mining In Tanzania

- Dam Ring Height Loesche Vertical Mill

- Type Roll Mining Mill

- Description Grinding Jobdescription Grinding Miller

- How Gold Mining With A Ball Mill Works

- Mobile Gold Ore Jaw Crusher For Sale Nigeria

- Which Grinder Is Used For Powder Coating S Material Grinding