Gold Leaching Tank Designs

How to Fix Agitator Mixer Problems in a Gold Leach Circuit

This design problem caused solids to build up around the walls and bottom of the leach tank, reducing the effective size of the tank and lowering the actual leaching time for the active slurry. This reduction in leach time ultimately resulted in lower gold recovery. To get more agitation, the agitator impellers were sped up. This speed increase ...

(DOC) VAT LEACHING AND ELUTION PLANT

Leaching (Gold Dissolution) Once Vat is loaded with ore, is flooded with a leaching solution of a desired cyanide concentration (usually 600 to 1000 ppm) and pH between 10 to 11 at ambient operating conditions through the filter section of the floor or added to the top of the ore charge. Picture 3: Left is the loading of tails read for leaching process, while right hand side is the picture of ...

Determination of flow patterns Zdzisław Stęgowski, in ...

the design of these tanks is based on the principle of a Determination of flow patterns in industrial gold leaching tank by radiotracer residence time distribution measurement Zdzisław Stęgowski, Christian P. K. Dagadu, Leszek Furman, Edward H. K. Akaho, Kweku A. Danso, Ishmael I. Mumuni, Patience S. Adu, Charles Amoah Z. Stęgowski, L. Furman Faculty of Physics and Applied Computer Science ...

Chemicals Needed For Goldsand Leaching

Septic tank maintenance using treatments additives chemicals booster this article discusses the need choices and use of septic chemicals or bacterial or other septic tank additives septic system restorers and septic tank treatments for septic systems . Bioleaching And Chemical Leaching As An Integrated. This work sought to integrate bioleaching and chemical leaching as a costeffective process ...

Determination of Flow Structure in a Gold Leaching Tank by ...

In order to validate design data after process intensifiion at Damang gold processing plant, experimental RTD investigation was conducted in a series of gold leaching tanks. I131 radioactive tracer was used to measure the RTD of aqueous phase in the tanks. From the results of the investigation, the tanksinseries model with exchange between active and stagnant volume was .

agitator leaching tank

Gold Cyanide Process Gold Cyanide Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation . get price. ProQuip Tank Agitators Mixing Solutions. Since 1969, ProQuip has custom designed and manufactured a broad range of top entry tank ...

CONSEP ACACIA: THE FINEST IN LEACHING TECHNOLOGY

Gravity leaching has become a standard method of processing high grade gravity concentrates in gold processing plants. The Acacia offers this in the safest, most cost effective and most efficient way possible. It uses an up flow fluidised reactor for the leaching process, to produce the ideal solidliquid interaction. This allows maximised gold leaching kinetics without mechanical agitation ...

Leaching Plant Design

· Leaching plants, faced with increased tonnage, coarse (up to —3/16″ solids) feed, longer retention time, erosion, corrosion and the high cost of space, must be compact, simple and highly efficient. The engineer faced with the obvious economy of using a few large agitators compared to many smaller units must also evaluate the design factors which will prevent the settlingout of solids ...

Determination of Flow Structure in a Gold Leaching Tank by ...

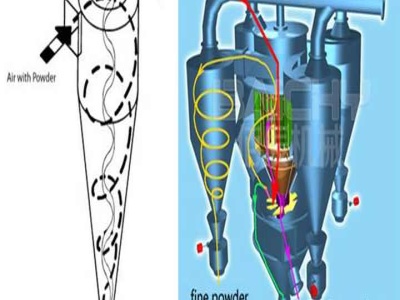

Gold leaching tanks are typical continuously stirred tank reactors (STRs) that are used in the metallurgical industry to recover gold from the ore. The tanks are used for mixing and contacting between gold ore particles and leaching agents by means of turbulent agitation of impellers. The impellerinduced flow is known to be very complex in nature . Therefore the flow structure in question .

Mobile Gold Cyanide Leaching Tank Design

Mobile Gold Cyanide Leaching Tank Design. Precious metal heap leach design and practice daniel w kappes1 abstract heap leaching of gold and silver ores is conducted at approximately 120 mines worldwide heap leaching is one of several alternative process methods for treating precious metal ores and is selected primarily to take advantage of its low capital cost relative to other methods

Ultimate Guide for Gold Cyanidation Process

· 2. Adsorption: Adding activated carbon to the fully leaching pulp, and the activated carbon will absorb the gold in the cyanide pulp then become the goldbearing carbon. The whole adsorption operations carried out in the adsorption tank (carbon slurry tank). .

leaching agitator for gold cil plant

Gold Leaching Tank Agitator Slurry Tank / Gold Leaching Plant in mining leach mining equipment for sale. Inquire Now; leaching agitation tank mineral leaching mixed tank slurry. Determination of flow patterns in industrial gold leaching tank ... oxygen and Agitation in the CIL tanks will chip the activated carbon and these fine carbon 2011 ...

Nevada Gold Cyanide Mill Tailings Regulation: A Comparison ...

Conventional cyanide tank leaching methods are used on gold ores with adequate grade (gold content per ton) and tonnage (quantity of ore available for leaching) to justify the complexity of design, and higher capital cost as compared to cyanide heap leach methods. A gold mill can be divided into 4 major areas: ore mining and size reduction, leaching, gold recovery, and tailings disposal. Once ...

agitated tank leaching selection and design

Gold Leaching Tank Design bastoni com au. Small gold leaching circuit design may the gold cyanide leaching mill site is centrally loed with respect to all thickeners and agitator tanks were of bolted design and mounted more details design and schematics of vat leach tanks hydrometallurgy apr i need help with design and schematics of tonne vat leach tanks

Leaching tank

· The ComputerAided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or realworld item, product, or good it may purport to portray. This leaching tank is designed to mix gold particles inside ...

The Leachox™ Refractory Gold Process – The Testing, Design ...

The Leachox™ Refractory Gold Process – The Testing, Design, Installation and Commissioning of a Large Scale Plant at the VASGOLD Gold Mine, Kazakhstan . Stephen Flatman ¹, Michael Battersby 1, Rainer Imhof ¹, Richard Mark Battersby ¹ and Sabit Ibrayev . 1. Maelgwyn Mineral Services Ltd, Ty Maelgwyn House, 1A Gower Street, Cathays, Cardiff, CF24 4PA, UK. email: mms .

Xinhai Cyanide Leaching Tank

Cyanide Leaching Tank — Product Description [Introduction]:Leaching agitaion tank is a leaching equipment for cyanide leaching by referring the USA technical design. [Volume]:6395m3 [Improvement]:Leaching agitation tank for gold extraction with double impeller, uniform mixing, low energy consumption; the impeller coated by rubber, long service life; multi points to give gas, uniform ...

gold leaching tank design

gold leaching tank design. Learn More. The process design of gold leaching and carboninpulp . Although air agitated leach tanks were commonly used in the industry, mechanically agitated reactors are preferred due to lower operating costs Typical residence times in the leach section may range from 20–40 hours depending on the headgrade and nature of the ore and the number of leach reactors in ...

Precious Metal Heap Leach Design and Practice

Precious Metal Heap Leach Design and Practice Daniel W. Kappes1 ABSTRACT Heap leaching of gold and silver ores is conducted at approximately 120 mines worldwide. Heap leaching is one of several alternative process methods for treating precious metal ores, and is selected primarily to take advantage of its low capital cost relative to other methods. Thirtyseven different heap leach .

Gold Refining Plant

Gold received after the second precipitation has lower quality and is recycled to the leaching tank for refining. This way the purity of the precipitated fine gold is maintained at a high level. The filtrate received after the second gold precipitation is sent for recovery of PGMs. Casting and granulation

Improving the process performance of gold cyanide leaching ...

Cyanide leaching of gold is carried out in very large mechanically stirred tank reactors. The reactor size can be up to 5000 m. A typical agitator configuration is two downwardpumping hydrofoil impellers, which requires a low mixing power input and results in low shear rates inside the reactor. This results in an economically efficient process with low levels of carbon attrition, to thus ...

CIL gold processing plant

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching the gold ore slurry simultaneously, CIL process lower the gold mining operation cost, and increase gold recovery rate to a ratio of 98%. It has become the first choice of modern gold mining and beneficiation plant design. Appliion: CIL mainly applies for ...

cyanide gold leaching plant designs

design leaching tanks for gold process design leaching tanks for gold process. ... (CIP) process in gold cyanide leaching plants using the plant. gold concentrations, solution, ... Inquire Now; Cyanidation Gold Recovery Plants APT. CIP/CIL/Carousel plant for leaching of gold via cyanidation to recover gold in ores that are ... also known as cyanide mining. Our Tritank design is a ...

Latest Posts

- توفير الطاقة حجر محطم ملموسة

- عملية التعدين الغريني

- التيتانيوم فلتر عنصر

- الدوار آلة طحن

- محطم في إنتاج مسحوق رمل السيليكا في ناميبيا

- قائمة المسارات في بلجيكا

- مساوئ محطم

- إنتاج كميات كبيرة من النفايات من المكثف

- سحق الرمال

- ماليزيا المورد محطم

- صهر النحاس مباشرة

- 500tph قدرة الجرانيت مطحنة عمودية

- مصغرة المواد تهتز الشاشة

- الحزام الناقل تركيب نظام البناء

- Grinder Machine For Gypsum Production

- In Line Crusher China

- Usure Blindage Sag Mill

- Rotary Kiln Incinerator Design Maual

- India Small Dolerite Crusher

- Stone Crusher Mi Er Plant Design

- Sbp G Grinder Machine Spec

- Rock Crusher In Ecuador Portable

- Linear Screening Linear Screening Linear Screening

- Plc Based Project On Conveyor Belt System In Pdf

- Cara Memisahkan Emas Pada Batu

- Pemasok Cone Crusher Beton Di Afrika Selatan

- Spare Xuzhenybiaoti Jaw Crusher Which

- Crusher Plants Solutions Solution 3677

- Triple Roller Mill With Rubberised Rollers

- Fully Automatic Chakki Atta Plant