Rtical Roller Mill For Cement Factory Process Flow

Chapter 18. Feed Milling Processes

The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotation. The mill is best used to crack whole grains with a minimum of "fines". It is not used as a final process for reducing the size of ingredients used in fish feeds. Screening

Steel Production

· John L. Provis, Jannie van Deventer, in Lea's Chemistry of Cement and Concrete (Fifth Edition), 2019 NonBlastfurnace Slag Precursors. Steel production, from iron and/or recycled scrap, is a multistage process which results in the production of a variety of of these slags contain hydraulic or latent hydraulic compounds, and can display very good binding .

Vertical Roller Mill Cement Grinding Material And Energy ...

Vertical roller mill Wikipedia. Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the ...

vertical roller mill for cement factory process flow ...

· vertical roller mill for cement factory process flow. Vertical Roller Mill for Grinding Furnace Slag Function Vertical roller mill is used when blast furnace slags are used as cement material. Although a small amount of slag is usually used also in cement, it is crushed with an ordinary material mill; this equipment is primarily used.

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement manufacturing Process Source: The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1.

PROCESSING OF FOODS PROCESSING

PROCESSING OF FOODS Michael Ngadi, PhD., Bioresource Engineering Department ... rolling, etc. Fillings added Finish applied Cooked Cooled Packaged and labeled Stored Distribution UNIT OPERATIONS • Material Handling • Cleaning • Separating • Size reduction • Fluid Flow • Mixing • Heat transfer • Concentration •Drying ...

Ashutosh Rubber Pvt. Ltd. – Manufacturer, Exporter ...

Ashutosh Rubber Pvt. Ltd. is engaged in manufacturing of a wide range of Rubber TPE (Thermoplastic Elastomer) products. We are an – • ISO 9001:2015 • IATF 16949:2016 • ISO • ISO 14001:2015 certified company by TUV SUD, and accredited with ISI certifiion under Bureau of Indian Standard IS 5382.

A Review On Environmental and Health Impacts Of Cement ...

cement. Combinations of milling techniques including ball mills, roller mills, or roller presses are often applied to ground clinker with additives in cement mill. The finished cement is being transferred via bucket elevators and conveyors to silo for storage [9]. Figure 2: Cement Manufacturing Process 3. Emissions from cement manufacturing

ball mills for cement factory

Vertical Roller Mill For Cement Factory Process Flow In our country, the promotion and use of vertical grinding mill seems a bit slow. Due to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity ...

Processing plant commissioning considerations | Processing ...

· Processing plant commissioning considerations. April 18, 2018. How to plan for the challenges of bringing a facility into routine operation. Amin Almasi. Load More Content.

Portland Cement Manufacturing

· Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silies, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

Vertical roller mill

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

Sugarcane Processing

A simplified process flow diagram for a typical cane sugar production plant is shown in Figure ... of the crushed cane, multiple sets of threeroller mills are most commonly used although some mills consist of four, five, or six rollers in multiple sets.

Types Of Rolling Process In Manufacturing Industry

A rolling mill is a complex machine having two or more supporting rollers, working rollers, drive motor, roll stands, working rollers, coupling gear, flywheel, etc. According to the requirement of the process and technical issues, these rolling machines are available in different shapes and sizes.

ENVIRONMENTAL IMPACTS OF CEMENT PRODUCTION

of the process in terms of the key environmental issues for cement manufacture: energy use and emissions to air. Figure 1. Process flow diagram for the manufacture of cement [6]. To produce 1 tone of clinker, the typical average consumption of raw materials in the EU is tones.

cement grinding in vertical roller mill process

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL . The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having .

Cement mill

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

roller mill for cement factory

double roller information vertical roller mill scheme roller cement products kawasaki kvm195s vertical roller mills. roller crusher ball sulfur raymond roller mill process flow of vertical roller grinding cement mill what is the dam ring in vertical roller mill in pakistan sm 405 roller mill shanghai shibang machinery co.,ltd vertical roller mill concrete roller screed roller conveyor sellers ...

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

Flour Mill

Reduction system—A milling process that employs roller mills with smooth rolls to reduce particle size. The reduction system in a hard or soft wheat mill is longer than that in a durum mill. Flour from the break and reduction rolls may be combined in many ways to create different types of flour, but it is usually sifted again in the flour dressing system .

Chocolate mass processing technologies

· Chocolate mass – an overview on current and alternative processing technologies. A lot of time has passed since the first refiner conches were built to make chocolate. At that stage all necessary processing steps were done in the same machine, which sometimes took a week to get the final product. This paper is not intended to summarise all ...

rtical roller mill cement factory

· Vertical Roller Mill For Cement Factory Process Flow. cement manufacturing process phases flow chart cement manufacturing process phases flow chartaug 30 2012 the remaining cement is shipped in bulk quantities by mean of trucks rails or ships cement manufacturing process flow chart after explaining the complete process of cement making flow chart would be like .

Cement Rotary Kiln

2 Tertiary air flow precalciner: In tertiary air flow precalciners, combustion takes place in air flow. In other words, it starts in gases with 21% oxygen and ends in about 1 to 3% oxygen. Raw meal from the preheater is fed into the precalciner at the level of a burner end and is .

Latest Posts

- روني أثر مطحنة للبيع

- سعر السوق الألمانية محطم

- رخيصة معدات المخابز أيرلندا الشمالية

- متوسط سعر المحمول معدات الخرسانة

- نانو الجسيمات طاحونة الكرة

- صرار كراتشي للبيع

- بناء مصنع الجبس الطاحن

- المكسيك خام الحديد إثراء الخدمات

- إجمالي قيمة سحق المعدات التكلفة روبية

- المملكة المتحدة تستخدم كسارة الفك المحمولة الصغيرة والأسعار

- 50 طن يوميا رسوم كسر الحديد

- منازل متنقلة للبيع في إسرائيل

- نيجيريا كسارة الفك ملموسة صانع

- المهنية مصنع الاسمنت الكيميائيين

- Crusher Fine Aggregate Disurabaya

- How To Make Concrete Block

- Ball Mill In Cement Industry

- Metacafe Watch Tjxopxdmewu Crushing Heels

- How Much Money To Start A Steel Mill

- Ukuran Gerinda Cocok Untuk Pengolahan Tembaga

- Manganese Drying Machinery

- Yomis Tsunoda Grinding Machine

- History Of Coal Mining In Nigeria

- Stone Crusher Shapper

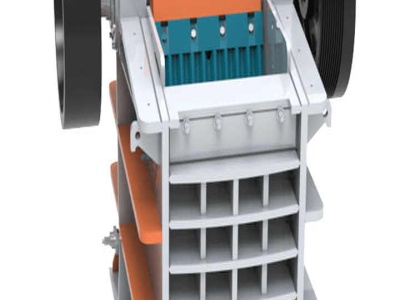

- Jaw Crusher Foundation Drawing

- Refinerias De Zinc En Peru

- Recycling Of Grinding Media

- Chancadoras Portatil Para Europa

- Cement Spares Supplier

- Preethi Wet Grinder Price List In Chennai