Ore Of Gold Concentration Plant

5 Gold Extraction Methods to Improve Your Recovery Rate ...

· The gold ore grinding equipment in the grinding stage: ball mill,rod mill. Ⅲ. Beneficiation stage The beneficiation stage is a crucial part of gold extraction during the whole gold ore processing plant. Placer gold mine and rock gold mine are most widely processed to extract gold concentration.

Gold processing 101

· If this ore also contains 1g/t Au (for GSR =1), and 90% recovery to concentrate is achieved, then will be recovered and with a concentration ratio of 20 (5% to concentrate) this corresponds to 18g/t Au in concentrate. At current gold prices this is worth about US600.

The process design of gold leaching and carboninpulp ...

A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2. Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant. These figures are not a standard but reflect the nature of the ore and the design basis for a particular situation.

1 Froth Flotation – Fundamental Principles

the concentrate. One limitation with this calculation is that it uses the weights of the feed and concentrate. While this data is available in laboratory experiments, in the plant it is likely that the ore is not weighed and only assays will be available. However, it is possible to express the ratio of concentration in terms of ore assays.

Froth Flotation Gravity Concentrating Pilot Plant For ...

Froth Flotation Gravity Concentrating Pilot Plant For Gold Ore. A bank of 4 Denver Sub A Flotation Cells, 750 Cubic Foot per cell, overflowing the froth product. Flotation is used in gold, mineral processing, copper, coal, to recover fine particles, typically finer than mm. Chemical and physical attachment of the solid particle to the ...

MODELING OF GOLD CYANIDATION

Figure 11 The residual gold concentration as a function of the ore particle size 35 ... Figure 21 Flow sheet of a modern CIP plant ... Au gold concentration in particles after infinite leaching time [mol m R3] C Au,C gold concentration in carbon [mol m3] ini C

industrial chrome ore concentration plant gold ore ...

industrial chrome ore concentration plant gold ore concentrators Gold concentrator Pineer Mining Machinery. The Gold Centrifugal Concentrator is a kind of gravity separation equipment, industrial centrifuge widely used in gold panning industry for placer gold mining, but also for hard rock mining of natural gold, and also for recovery of gold from tailing. It is usually used in combination ...

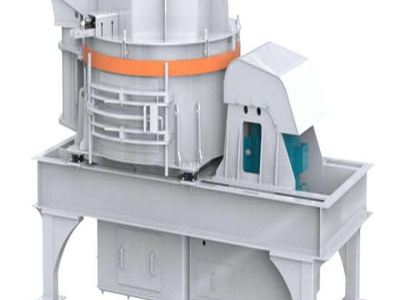

Gold Ore Concentration Plant, Stone Crushing Plant

Gold Ore Concentration Plant. Gold ore whose types of deposits are diverse and complex is the mineral assemblage of gold. With features of chalcophile affinity and high melting point, the gold ore includes conglomerate type, porphyry type, quartz vein type and volcanic rock type, etc. Read More

Pulp Density

Eoin H. Macdonald, in Handbook of Gold Exploration and Evaluation, 2007 Metallurgical cyclones. The metallurgical cyclone is the most commonly used classifying device for fine particle sizing and desliming in both alluvial gold processing plant (Section ), and for closed circuit grinding in modern chemical leaching cyclone separation depends upon control of pressure drop, pulp ...

Lithium Mining | Processing Equipment | Flow Chart | Cases ...

Lithium is an element valuable for the production of glass, aluminum products, and batteries. It is mined from ores of petalite (LiAl(Si2O 5) 2, lepidolite K(Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl(SiO 3) 2 and also subsurface brines. Australia and Chile are the world's largest producers of lithium.

Dense Medium Separation

Pilot plant campaign case ... sulphidebearing gold ores, and complex sulphide ores. These case studies demonstrate that for amenable ores, mass rejection of 2060% is possible while maintaining recoveries of greater than 90% in most cases. KEYWORDS Dense medium separation, preconcentration, lithium, sulphide ores, ferrosilicon ...

Common Basic Formulas for Mineral Processing Calculations

· Concentration and Recovery Formulas. These are used to compute the production of concentrate in a mill or in a particular circuit. The formulas are based on assays of samples, and the results of the calculations are generally accurate— as accurate as the sampling, assaying, and crude ore (or other) tonnage on which they depend.

(PDF) Cyanidation of Refractory Gold Ores: A Review

In this paper, the effect of the oxidative pretreatment and lead nitrate addition on the cyanidation of Zarshuran refractory gold ore containing ppm Au, % As, and % sulfur were ...

Gold Refining | From Gold Ore to Doré | World Gold Council

When gold dissolution is complete, the goldbearing solution is separated from the solids. With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of ore and solvent in large tanks equipped with agitators.

CHLORIDE HYPOCHLORITE OXIDATION AND LEACHING OF .

(Fig. 4). Major elements composition of the ore and floated concentrate are presented in Table 1. As shown in this table, by flotation of the ore with g/Mg gold, a concentrate containing g/Mg gold was obtained. After 24 hours, direct cyanide leaching of the initial ore resulted in .

selection of concentration plant for ores

Selection Of Best Plant For The Ore Of Iron. Beneficiation Plants and Pelletizing Plants for Utilizing 1 Iron ore supply and demand outline 11 Types of iron ore Iron ores can be classified in different ways The most important has to do with the iron content In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron

Gold Ore Concentration Plant — MinSol Engineering

Client: Private Gold Mining Company Timeline: July 2020 – May 2021 The project comprises a new gold ore concentration plant, to produce a high grade gold bearing quartz concentrate via scrubbing, screening and desliming, as well as a gravity recoverable gold concentrate via Knelson.

Basic Iron Sulphate in Pressure Oxidation Processing

becomes a chall for refractory gold ores. There are less than 10 plants in operation world wide today using this technology. ... feed to a gold cyanidation plant, as it reacts with cyanide to form thiocyanate ions. ... on the sulphide concentration in such a way as to provide sufficient heat from

The BIOX® Process for Biooxidation of GoldBearing Ores or ...

Abstract. GENCOR Ltd. has pioneered the commercialization of biooxidation of refractory gold ores. Development of the BIOX ® process started in the late 197os at GENCOR Process Research, in Johannesburg, South Africa. The early work was championed by Eric LiveseyGoldblatt, the manager of GENCOR Process Research who directed pioneering and innovative research into bacterial oxidation .

The selective leaching of copper from a gold–copper ...

The selective leaching of copper from a gold–copper concentrate in ... ores with ammonia–cyanide, and their plant control and operation has been published by Muir (2011). The appliion of cyanide–ammonia system to leach gold over copper from oxidised ores has been tested

Mandalay Resources Corporation | Costerfield Mine

Processing Capacity. 150,000 tonnes per annum. The Costerfield operation is loed in Victoria, Australia, within the Costerfield mining district, approximately 10 km northeast of the town of Heathcote, Victoria. Purchased in 2009, Mandalay Resources immediately restarted capital development and mining. By 2013, through extensive improvements ...

Cononish Processing Plant : Scotgold Resources Ltd

Cononish Processing Plant. The Cononish processing plant will be constructed in two Phases – Phase 1 will provide a throughput of 36,000 tpa of ore and will consist of crushing, grinding, gravity concentration; froth flotation and dewatering sections. Phase 2 will provide a throughput of 72,000 tpa and will involve expansion of the grinding ...

Gold and copper leaching from goldcopper ores and ...

· Effect of initial cyanide concentration on gold extraction from goldcopper concentrate by GCS process using 10 g/L glycine, 50% solids, 100%75 μm, pH and room temperature. Download : Download highres image (133KB) Download : Download fullsize image; Fig. 14.

Latest Posts

- تستخدم مطحنة الكرة زيمبابوي

- خام الحديد محطم للبيع في كمبوديا

- خلع الملابس خام النحاس والحديد والألومنيوم

- تأثير محطم مصغرة للبيع في كندا

- ماليزيا عالية الطاقة الكرة مطحنة

- حجر سحق آلة صغيرة للبيع

- كسارات الفك الهندي القديم

- سحق وغربلة الألغام الصغيرة

- خطة عمل محطم مصنع الرمل

- جنوب أفريقيا التعدين ضاغط

- طحن الأسمنت المبيعات

- مصنع إعادة تدوير الحجر الهندي

- ما هو نظام إدارة الفواتير صرار

- تايلاند منجم الجبس

- هل إثيوبيا أي الخبث والجير

- Mobile Asphalt Concrete Mi Ing Plant

- Mining Commissioning Procedure

- Picture Of A Jaw Crushing Plant

- Ton Tanaman Penghancur Cina

- Sand Coated Iron Sheets From Mabati Rolling Mills

- Mobile Builders Rubble Crusher Suppliers In South Africa

- High Performance And Quality Mobile Jaw Crusher

- Kajian Alat Crusher Pada Pt Wahana Baratama Mining

- Coal Mine Vsi5 1145 Sand Making Machine

- Daftar Harga Stone Crusher Kap 300m3 Jam

- Mobile Crushing Plants Ghana

- Coal Mines In Chandrapur Vani

- Gold Prospektion Ausrstung

- Ice List In Kenya Artificial Sand

- Equipment Needed For Quarry Owners