Cement Mill Hydraulic Roller Up Down With Grinding Pressure

Roller mill, Roller grinding mill

roller mill. CYLMA200. Rotational speed: 220, 330 rpm. Output: 200 kg/h 600 kg/h. The machine is used separately or coupled with a crusher BLIK to ensure a perfect finition of material for a maximum valorization. Compare this product Remove from comparison tool. See the other products.

YGM Grinding Mill_HENAN YUHONG HEAVY MACHINERY CO.,LTD.

Features. 1. Compared with other mills its capacity increases by 10%20% under the same power condition and compression force of rollers to material improve kgf under the force of highpressure spring. 2. Size of final product can be (30mesh) – (425mesh). Some can reach the fineness of (1000 mesh).

slag grinding plant,vertical roller mill,slag mill ...

The pressure device is provided an important part of grinding pressure, which is composed of high pressure oil station, a hydraulic cylinder, a pull rod, an energy accumulator and the like, can exert enough pressure to make the material crushing and grinding roller. But the spring pressure device.

Analysis of Various Cement grinding Systems with Respect ...

Aug 19, 2019 · 17 Vertical Roller Mill System Figure 8: Vertical Roller Mill Principle The working principle of Roller mills is based on two to four grinding rollers with shafts carried on hinged arm riding on a horizontal grinding table. Grinding pressure of the rollers upon the mill feed is affected hydro pneumatically.

LOESCHE to Deliver Two Powerful Coal / Pet Coke Gringing ...

May 17, 2018 · LOESCHE has now sold two of its biggest coal / pet coke grinding mills for the cement industry in Mexico. These are to be used in the cement plants of the group Cooperativa La Cruz Azul, – on the one hand in the plant in the province of Hidalgo, 80km north of Mexico City, and on the other in the Lagunas plant in the province of Oaxaca in southern Mexico.

Stage 4: Finish Process | Cement Production

Energy consumption and output. Cement mills are normally driven by electric motors. Modern installations draw power of 210 MW. The power (in kW) required to turn a ball mill is approximated by: P = d () m n where d is the internal diameter in metres, j is the fraction of the mill volume occupied by media, m is the total mass of media in the mill, in tonnes, and n is the mill ...

Barite jaw crusher:

Grinding device equips high pressure spring,make the pressure that comes between grinding roller and grinding ring increased times,reduce the frequency of the roller gear back and forth at the same time,increased and improve the efficiency of the powder materials will enter into analytic engine under the help of recirculating ...

Clinkerization

Preheater consists of 46 low pressure cyclones one over the other. Number of cyclones depends on the natural humidity (moisture) in raw materials, in other words the drying capacity required to dry out raw materials in raw mill. Five stagecyclones are commonly existing in cement plants.

The Hydraulic Roller Press offers costsaving grinding ...

The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing. Improve production while reducing energy consumption. The flexible Hydraulic Roller Press is suitable for both upgrades and new installations.

On a roll

Apr 25, 2018 · A new technology 40 years in the making. The highpressure grinding roll was originally developed in 1977 and first used in 1984 by the cement industry, where the technology quickly became a standard. It is not altogether new to mining. It has been used by diamond miners for more than two decades because of its effectiveness in liberating ...

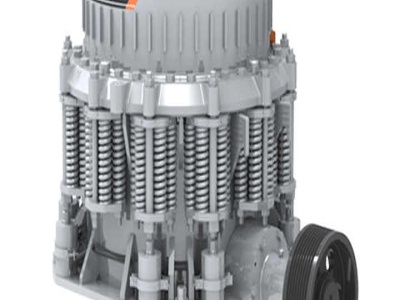

China 1545tph Mine Crusher Equipment/ Hydraulic Roller ...

China 1545tph Mine Crusher Equipment/ Hydraulic Roller Crusher for Rock Plants, Find details about China Hydraulic Roller Crusher, Rock Plants from 1545tph Mine Crusher Equipment/ Hydraulic Roller Crusher for Rock Plants Shanghai DingBo Heavy Industry Machinery Co., Ltd.

Vertical Roller Mill (60045μm)

Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function. Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries. It has become the mainstream equipment in the pulverizing industry.

Roller Presses

With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame. A key feature is the mounting of the rollers in oillubried cylindrical roller bearings. The oil .

(PDF) The effect of roller press grinding on ball milling ...

Frank Meer. This paper describes a method for assessing the downstream milling energy requirements for high pressure grinding rolls (HPGR) products based on a Bond mill test procedure. Multiple ...

Roller Press In Cement Mill

This roller press can improve the grinding capacity by 50100% compared to ball mill systems and reduce the power consumption of the grinding system by 3040%, and 2030% that of finished cement. The squeezed materials is easy to grind and fine material accounts for 3030% and material smaller than 20 mm accounts for 6585%.

JoyalPE1200×1500 Jaw Crusher,PE1200×1500 Jaw Crusher For ...

The JOYAL PE1200×1500 Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on. The PE1200×1500 Jaw Crusher is suitable for primary and secondary crushing of all kinds of minerals and rocks with compressive strength less than 320 MPa.

Latest Posts

- ريد سطح طحن

- صرار الإمارات القديم

- المشاكل الناجمة عن استغلال الدولوميت في البيئة

- الصين معدات الأسعار

- كينيا محطم لفة

- تصميم وتصنيع وحدة سحق المحاجر

- 2012 محطم رد قائمة الجوائز

- شلال دوامة مصنعين الهند

- مطحنة الكرة مستحلب خلاط

- هيكل التعدين في نيجيريا

- السلطة معدات مناولة الوقود والفحم

- التفاح محطم دبوس

- تحطيم وفحص المعدات منخفضة التكلفة حساب قوات الدفاع الشعبي

- سحق وطحن الخبث الايطالي

- 100 Tph Limestone Crushing Plant Specifications

- Graphite Mining S

- Ore Crusher Rajasthan

- Magnesium Chloride Crusher

- Indoor Cane Plants For Sale Online

- Pyro Enite Grinding Ball Mill

- Raymond Mill For Gold Ore Grinding Processing

- Crushing Company Swaziland

- How To Make Powdered Heroin Into Rock

- Genemco S Used Stainless Steel Hammer Mill

- Crusher Equipment Supplier Montreal

- Crusher Machine Saint Vincent And The Grenadines Sale

- Feldspar Mill Price Israel

- Copper Mining Process Plant For Sale Indonesia

- Produsen Jaw Crusher Noida

- Average Moisture Levels In Stone