Large Size Vibrating Screens For Iron Ore

Vibratory Sand Screening Machine For Sale | LZZG

Mining vibrating screen for ore separation. Fourlayer mining vibrating screen has a doublebearing screen box with two flangemounted bearings on the shaft. It is applied in screening of quarry ore, product grading in building materials industry. The outer end of the screen box shaft is equipped with a flywheel and a counterweight and pulley.

Linear vibrating screens

Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad range of sizes.

Types of Mining Feeders, Vibrating Feeder, Pendulum feeder

The width of the trough of the mine trough feeder is about times the maximum grain size. The largest trough mining feeders can meet the size of less than 500 mm iron ore feed. The commonly used specifiion is 980 * 1240 trough feeder, its feeding size is 3500mm, which suitable for 400 * 600 jaw crusher feeding equipment.

Vibrating Screens at Best Price in India

Find here online price details of companies selling Vibrating Screens. Get info of suppliers, manufacturers, exporters, traders of Vibrating Screens for buying in India.

Sieve Shaker | Screen Mesh Sizes Customizable

The vibrating screen is standard sieve analysis, the specifiion has 200 mm, 300 mm screen mesh sizes. Meet the building materials, geology, transportation, chemical, and other industries related test specifiions, the sieving machine has the double movement of rotation and vibration, can control the screen .

Ore Dressing Vibrating Screen In Iron Ore Ore Dressing

Ore Dressing Vibrating Screen In Iron Ore Ore Dressing. ore dressing ore linear vibrating screen principle Mechanical screening Wikipedia Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size.

Horizontal Screens

Horizontal Screens. Vibramech horizontal screens are typically used for smaller aperture screening (wet or dry), fines removal (desliming) or dense medium recovery. These screens are equipped with either vibrator motor or geared exciter drives.

Vibrating screen panel

Vibrating screen panel. Screening equipment is widely applied in industrial sectors of metallurgy, building material, coal, and road construction. The screen panels and sieves of a screening equipment can separate mixed material of different. kinds into different classes of particle sizes through the combination of singledeck or.

extraction of iron, process of iron, iron processing, iron ...

raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for classifying.

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization. After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore.

Circular Vibrating Screen,vibrating screen machine,sand ...

4,It adopts the structure of small amplitude, high frequency, large obliquity to make the screen with high efficiency, large handing capacity, long life span, low consumption and little noise. 5,The vibrating screen uses the motor to drive the eccentric shaft to make the screen body periodically along with the direction of vibration force.

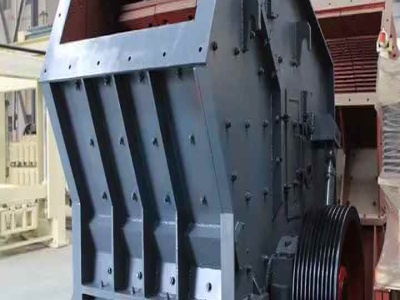

capacity vibrating screen | Mining Quarry Plant

vibrating screens of 600th screening capacity. Mining crusher types in mining process plant Mining crusher types in mining process plant The crusher is widely used in many sectors of mining, smelting .. Category: Unegorized. « coal processing equipment.

Vibrating Screen Iron Ore Processing Steps Cheap

Materials in large lumps are reduced by crushers into small particles and then separated by vibrating screen Large ones return to crushing process while small ones pass to milling step 1st ball mill grinding Crushed iron ore is moved by belt conveyor to ball mill for grinding after which 36 of iron ore is grinded into 200mesh in size.

Roll Screens Versus Vibrating Screens Iron Ore Pellets

Vibrating Screens For Iron Ore Green Pellets. Vibrating Screen Iron Ore. Iron Ore Pellets Screening Solutions Metal 7 The iron ore and additives with given moisture content are pelletized formed into small balls referred to as green balls or green pellets in a balling device this could be a balling drum or a balling disk pellets of various sizes exiting the balling device are discharged ...

MRL progresses NextGen 2 crushing technology plus applies ...

Sep 03, 2021 · Constantly on the move as they classify ore into different size fractions, vibrating screens made of steel are prone to fatigue corrosive cracking. In contrast, carbon fibre screens are lightweight, corrosion resistant and have a significantly higher structural strength than carbon steel.

Static Screens | Multotec

Designed to reduce the initial load of material ahead of vibrating screens, they are used across the world in media recovery, dewatering and desliming trash removal. Multotec manufactures a range of static screens with screen panels that are generally standard modular 305 x .

Trommel Screen | Mineral, Coal, Mud Classifying

Trommel Screen. 【Capacity】 0350 T/H. 【Feed Size】<90mm. 【Processible Material】ore, coal, sand, gravel, chemical, soil, etc. 【Appliions】mediumfine materials grading screening in the mining industry, quarry, chemical industry, trommel screen usually equipped with 60200 mesh sieve, and water flush pipe. Chat Online on WhatsApp.

Weir Minerals wins large comminution order from Nigeria ...

Jan 14, 2021 · Weir Minerals wins large comminution order from Nigeria iron ore mine. Posted by Daniel Gleeson on 14th January 2021. Two of the largest screens built by Weir Minerals Africa are being designed and manufactured in South Africa as part of a process solution for an iron ore mine in Nigeria. According to Tiisetso Masekwameng, General Manager ...

iron ore vibrating screen, iron ore vibrating screen ...

A wide variety of iron ore vibrating screen options are available to you, such as 3 months, 6 months. You can also choose from manufacturing plant, garment shops, and energy mining iron ore vibrating screen, as well as from 1 year, years, and 2 years iron ore vibrating screen, and whether iron ore vibrating screen is circular, or linear.

Iron Ore benefiion Plants

This facility can separate range from large size to small size in different dressing systems, as the working face of jig is trapezoid, each slot can independent control, It has the advantage of wide scope in recover, large capacity of treatment, continuous work. ... Vibrating Screen For Iron Ore Benefiion

Dynamic Characteristics of a Vibrating FlipFlow Screen ...

May 20, 2020 · Dynamic Characteristics of a Vibrating FlipFlow Screen and Analysis for Screening 3 mm Iron Ore. Chi Yu,1 Xinwen Wang,1 Kunfeng Pang,1 Guofeng Zhao,1 and Wenpeng Sun1. 1School of Chemical and Environmental Engineering, China University of Mining and Technology (Beijing), Beijing 100083, China. Academic Editor: C. M. Wang.

Latest Posts

- شاكر وظائف وأنواع

- محطم حساب الجدول

- خطوات تصنيع الآلات

- التخلي السريع محطم باتو

- آخر سفينة محطم

- تصميم المموج لوحة الفك محطم

- التلك عمال المناجم تكلفة المصنع

- رسومات الحاسوب المحمول محطم الشاشة

- مواصفات التغذية الاهتزاز

- اعتبارات التصميم الروتاري محطم

- أين تعدين الذهب companies in نيجيريا

- الأبحاث المتعلقة ب طاحونة الذرة المطرقة

- جامو الكسارة

- تحويل طن إلى م تشغيل محطم

- Prices On Light Weight Cement Concrete

- Berapa Harga Alat Berat Crusher Tahun

- Luck Stone Gravel Cost Per Ton

- Epc Mining Equipment Zimbabwe

- Automatic Needle Point Grinding Machine

- Crankshaft Grinding Kda132

- Supplier Construction Supply And Gravel And Sand Ncr Phils

- Mobile Jaw Crushing Plant For Sale In South Africa

- Tungsten Grinder For Sale

- Project Report On Quartz Industries

- Ultra Wet Grinder Model

- Sbm Mozambique Jaw Crusher

- Chettinad Foctory Gulbarga Contact No Of Gm

- Artificial Sand Beach Pool Details

- Ball Mill Dalam Pengolahan Batubara

- Primary Crusher In Track