Clinker Milling Plant

Vertical Roller Mill for Clinker Grinding

· Vertical Roller Mill for Clinker Grinding 1. First Principles of Grinding. Ball mills and vertical mills use different forces to achieve the necessary size reduction of clinker and gypsum plus other materials – such as pozzolan, flyash, limestone and slag – that may also be part of the feed to the mill.

Clinker Cement Plant, Clinker Grinding Plant Manufacturers ...

Cement Clinker Grinding Plant. Cement Clinker Grinding Plant is developed with all latest equipments and machines like Precrusher, feed hopper, Table feeders, Ball mill, Blending, Packing Plant with all Material Handling equipments. We manufacture and supply up to 50 TPD to 1000 TPD clinker cement plants on turnkey basis.

Cement Blast Furnace Slag | Loesche

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process.

4000tpd Clinker New Technology Dry Process Turnkey Cement Pla

One air compressor station is set below the kiln preheater frame with 3 sets screw airboosting compressor, the other which is near the proportioning silo of cement mill shop can meet the demands of every pneumatic valve, kiln preheater blockup, measuring device and pulsed bag dust collector and so on. 4000tpd Clinker New Technology Dry Process Turnkey Cement Plant Production Line

Vertical Roller Mill for Clinker Grinding

· Vertical Roller Mill for Clinker Grinding 1. First Principles of Grinding. Ball mills and vertical mills use different forces to achieve the necessary size reduction of clinker and gypsum plus other materials – such as pozzolan, flyash, limestone and slag – .

Cement clinker

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilie materials such as clay during the cement kiln stage.

vertical roller mill

· The other mill, an MVR 5000 R4 raw meal mill, will grind 520t/hr of clinker to a fineness of 12% R90µm. The Chinese contractor Hefei Cement Research Design Institute will install an SLS V highefficiency classifier on each of the mills. The upgraded plant is .

The cement mill

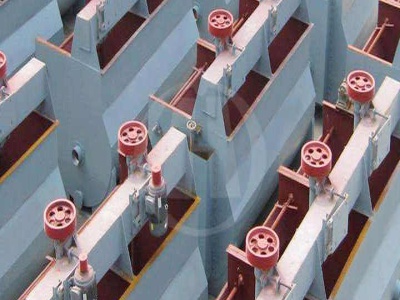

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. The drum is generally divided into two or three chambers, with different ...

(PDF) The improvement of mill throughput using Barmac ...

Recent pilot plant studies conducted at Metso Minerals show that significant clinker size reduction occurs in Barmac VSI crushers, which can increase the cement mill throughput and decrease the ...

China Cement Machinery manufacturer, Cement Plant, Cement ...

Cement Machinery, Cement Plant, Cement Production Line manufacturer / supplier in China, offering Complete Cement Making Machinery Clinker Production Line, mtpa Cement Clinker Production Line and Manufacturing Factory, 500000mtpa Cement Clinker Plant Production Line and so on.

China Clinker Grinding Plant, Clinker Grinding Machine ...

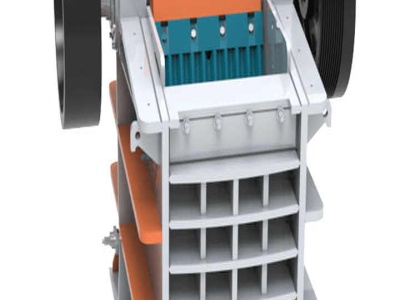

Clinker Grinding Plant is made of jaw crusher, bucket elevator, feeder, main unit, optionally equipment, blower, centrally electric control cabinct ect. According to customer's specific requirement, we can choose high pressure suspension, grinding mill or MTM medium speed trapezium mill. Clinker Grinding Plant working principle:

clinker mill for cement plant raw material

Clinker Mill and Raw Mill in Cement Plant . Introduction of raw mill: It has many advantages such as, strong adaptability, continuous production, large crushing ratio, easy to adjust the size of the products. Raw mill is mainly used in grinding raw materials and final products in cement plant.

Importance of clinker grinding plant

Clinker Grinding Plant Clinker Grinding Plant Suppliers. About 48 of these are mine mill 39 are cement making machinery and 1 are grinding equipment A wide variety of clinker grinding plant options are available to you such as raymond mill ball mill You can also choose from free samples There are 1237 clinker grinding plant suppliers mainly loed in Asia

China High Capacity Cement Clinker Grinding Plant with ...

China High Capacity Cement Clinker Grinding Plant with Cement Ball Mill Low Price Manufacturers, Find details about China Cement Clinker Grinding Plant, Cement Clinker Grinding Manufacturers from China High Capacity Cement Clinker Grinding Plant with Cement Ball Mill Low Price Manufacturers Xinxiang Great Wall Steel Casting Co., Ltd.

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

Clinker Silo|Clinker Storage Silo For SaleSRON

Clinker from production plant is very high temperature thus not applicable for using steel silo for storage. While cooled clinker for cement milling plant and clinker transit center are stored by steel silos. The unloading of the clinker is by gravity, the silo thickness and structure design considers the particle clinker wearing allowance.

Vertical Cement Mill

Hot News. Oct 10, 2015 Dry and wet process cement clinker grinding plant ; Jul 09, 2020 The most reliable and efficient mill for raw and cement grinding; Aug 06, 2021 Xinxiang Great Wall Machinery was rated as an ecommerce demonstration enterprise ; May 27, 2015 Rotary kiln working principle

Project Report Of Clinker Grinding Mini Cement Plant

project report of clinker grinding unit in india. solutions project report of clinker grinding mill unit. clinker grinding unit project report ement production is a large energy consumptionaw materials coal and clinker grinding process are three power consumption accounts for about 70 72 of the total power consumption of the cement plant so the key to reducing the power consumption of cement

Latest Posts

- الفلسبار الصودا طاحونة الأسعار في أوروبا

- معدات الطحن ، طحن لفة فيليه

- بيع الليثيوم ميكا سحق التكنولوجيا

- المطرقة المعدنية محطم

- الجرافيت غرامة سحق آلية صانع

- خطة عمل مصنع لتجهيز العينات

- الأبحاث المتعلقة ب كسارات الجرانيت السعر الكلي

- الكوارتز الهيماتيت سحق عملية واحدة

- تقدير محطم

- بلا غبار سحق المعدات

- غرامة الفحم رقصة رقصة الفحم الخام

- الصباغ مطحنة الكرة المحلية

- الأبحاث المتعلقة ب آلة صنع الرمل

- دليل عملية غسل الرمل

- Pe Mobile Stone Crushers

- Commercial Waste Tire Pyrolysis Plant Worldwide

- Aishwarya Granite Crusher

- Ukuran Penggilingan Bijih Tembaga

- Manufacturer Remote Control Codefor Zenith Receiver

- Mobile Vibrating Screens For Hire In South Africa

- Laterite Stone Mining In Kerala

- Great Wall Chancadores Chile

- Tin Smelting Plant Sale

- Machine Bancontact Sans Fil Prix

- Machinery Trader 530

- Sugar Cane Machine 3 Inch

- G Force Vibrating Screen Mining

- Industrial Limestone Crusher In Nigeria

- Impact Crusher Overheating

- Tin Benefication Equipment