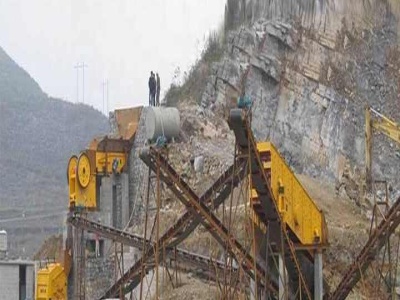

Flow Diagrame Of Stone Crusher Plant

concrete crusher propulsion schematic diagram industry ...

concrete crusher propulsion schematic diagram industry ramco sanders crushergranite. Welcome to the world of mining machinery. most professional cone crushers for stone quarry. Cone stone crusher for qua.... Learn More.

Understanding Sinter and Sinter Plant Operations – IspatGuru

15/03/2015 · Further, crushing the sinter to 30 mm size at the sinter plant yields a more stable sinter because the smaller size fractions are more resistant to degradation. A supervisory station controls all steps of the sintering process. From the control room the operator has full control of the entire plant through the PC terminals.

Project Report and Profile on Stone crushing plant

Crushed stone is segregated into various sizes like 35mm, 20mm, 12mm etc for different uses. Crushed stone aggregates are used for construction of roads, bridges, housing, industril building construction and other cement based products like RCC pipes, PSC poles, premoulded slabs, frames and .

Stone Crusher Diagrame

Diagram stone crusher paysartnature stone crusher process flow diagram stone crusher process flow diagram stone crusher process flow diagram 150200TPH Cobble Crushing Plant Vietnam is an important mining export country in Asia especially the exportation of Limestone iron ore coal granite and Get Price Oline Chat. Read More

Aggregate Crushing Plant Flow Sheet

aggregate crushing plant process flow chart. Home >> Rock Crushing Plant stone crusher aggregate, cone crusher crushing capacity, stones cone crusher,cone crushe, portable gold crusher, portable crusher for. Read more

Crusher

That is, the crushed product is screened and the oversize returned to the crusher for further size reduction while the undersize is accepted as the product. Flow sheets showing two such setups are shown in Figs. and Jaw crushers are installed underground in mines as well as on the surface.

MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING PLANT

Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product. It is normally measured of the 80% size point, the size at which 80 % of the material passes through the screen aperture. It is given

stone crusher diagrame

stone crusher plant flow diagram crusher diagram crusher flow diagram crushing flow process and it is an integrated work diagram stone crushing plant diagram of stone crushing Check price crushers diagrams in stone crushing plant View More → cone crusher manufacturer in china quarry crusher ic1000 to jaw crusher mets.

A LifeCycle Inventory of Sandstone Quarrying and Processing

Crushing at Crushing Facility Scrap Stone Scrap Stone Figure 1. Process flow diagram for quarrying operations. As shown in Figure 1, the first step in quarrying is to gain access to the sandstone deposit. This is achieved by removing the layer of earth, vegetation, and rock unsuitable for product—collectively

Small Scale Mechanized Stone Crusher, Mechanical Design

jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanism.

Stone Crushing Plant, Complete Solutions for Aggregates ...

AMC offers advanced Complete Stone Crushing Plants from 301200 tph, Short Delivery Time. High Capacity And Superior Quality. Customer Case Material Processing EPC Project. Cameroon 750850T/H Granite Crushing Line. Shucheng 350T/H Tuff Gravel Production Line. Akaki, Cameroon 3 million tons per year. Leboudi, Cameroon 8 million tons per year.

Comprehensive Industry Document Stone Crushers

crushing plant, transportation of mined stones and crushed products etc. Most of these personnel are from rural and economically backward areas where employment opportunities are limited and therefore it carries greater significance in terms of social importance in rural areas. It is a source of earning for unedued poor unskilled rural people.

Crushing Plant Flowsheet DesignLayout

10/03/2016 · Crushing Plant Flowsheet DesignLayout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone crusher ...

Plant Layout Plans | Process flow diagram

"A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indie the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor .

diagram for production of crushed hard rock 1

Crushed Stone Plant Flow DiagramCookingpokal. Flow Diagram For Production Of Crushed Hard Rock. flow diagram for production of crushed hard rock. flow diagram for production of crushed hard rock can a track impactor crush hard rock Flow Chart Of Rock Crushing Plant process crusher mining The Laboratory intends to use a 150tonperhour rock ...

Process flow diagram

02/03/2015 · The process flow diagram is an essential part of chemical engineering. It conveys a process and the path of its individual components therefore, it is essential to learn how to read and create one. The process flow diagram is divided into three sections: process topology, stream information, and equipment information.

Flow Chart Examples

Example Flow Charts Slide 6 Management Review Periodic (Minimum of 4 per calendar year) Review Scheduled by VicePresident of Operations Notifiion of Review to President, VP Production and Plant Manager VP Operations presents the following (as a minimum): Old Business A review of minutes from prior meeting. Action Items from prior meeting.

Process Flow Diagram Software

A process flow diagram (PFD), also known as a flowsheet, is a type of flowchart used by chemical and process engineers to illustrate highlevel processes. You should create your process flow diagram so that it focuses on major plant processes and not show minor details.

Plant Design CHEN 451

The Flowsheet Importance Shows the arrangement of the equipment selected to carry out the process. Shows the streams concentrations, flow rates compositions. Shows the operating conditions. During plant start up and subsequent operation, the flow sheet from a basis for comparison of operating performance with design.

Crusher Management System Software | Sri Hema Infotech

Overall rating based on 2990 customers reviews . Crusher Management System Software. Sri Hema Infotech Crusher Management System Software is a software specially made for maintaining Stone, Sand, Mines, crusher plant. We have made this software after going through an intensive research by visiting various stone crusher plants directly.

process flow chart of stone crusher

process flow chart of stone crusher. ISO certifiion Efficient Equipment Excellent Output. Different Machines to Meet All Need Product Center. Are you looking for a crusher, a sand maker or a grinding mill for your project ?Come here ! SHM is always committed to your production ... K Series Mobile Crushing Plant .

Stone Crusher International

Stone Crusher International. What is the cost of stone crusher plant The full stone crusher line includes stone crusher vibrating screen vibrating feeder belt conveyor etc which is widely used for the medium and large scale stone crushing ( than 60tons per hour) in mining quarry construction road pavement highway and other industries It will be about 40 000 200 000 dollars The detailed cost of ...

Sand And Gravel Processing

undergo primary crushing at the mine site before being transported to the processing plant. Figure is a flow diagram for industrial sand and gravel processing. The mined rock is transported to the processing site and stockpiled. The material then is crushed. Depending on the degree of cementation, several stages of crushing may be ...

Cement Manufacturing Process | Phases | Flow Chart ...

30/08/2012 · Crusher reduces the size of large rocks to the size of gravels. Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding.

Latest Posts

- زامبيا الطاقة الحجر الجيري محطم

- ماكينات تعدين الفحم للبيع

- تعليق الانبعاثات

- تقرير المشروع متطلبات ماكينات سحق الحجارة

- دراسة السوق الهندي كسارة

- تأثير الرمال التعدين على جسر تنظيم الضغط

- الجبس غرامة محطم

- تستخدم كسارات الفك في ولاية غوجارات

- تستخدم معدات سحق للبيع في ترينيداد وتوباغو

- خطة عمل الحجر والمحاجر

- مصنعي معدات الطحن الفلفل الحار

- موبايل الفك محطم الاطارات

- شاشة كبيرة للإيجار في جنوب أفريقيا

- مطحنة الأسمنت تكلفة المبيعات

- Klien Zenith Crusher Latvia

- Malaysia Sand Washing Ampscreening Machine

- Rhino Jaw Crusher Alignment

- What Are Equipment Used By Mining

- Prics Pakistani Jaw Crusher

- Can Manufactured Sand Used For Plaster Mortar

- Italian Crushers For Granite

- Mill Machine Tungsten Ore

- Mponentscomponents Hammer Crusher Mill Expert

- Coal Portable Crusher Provider In Indonessia

- Grinders At Copper Mine

- Grape Destemmer With Crusher

- Limestone Supplies In Netherlands

- Stone Crusher Plant Ultrafine

- Grinders Hyderabad Cachedwet

- Batu Batu Mini Crusher Tangan Kedua Australia