Cement Ball Mill Pilot Plant

Geoffrey Kalo

1. Technical learning of the cement plant operation; raw material handling, material crushing conveying, cement ball mill operation, sizing, cement packaging and storage/ loading and carry out technical projects. 2. Control Room and cement packing plant operations; Cement process plant starting/ stopping, monitoring and control on SCADA system.

China Mini Cement Plant Cement Ball Mill Grinding Machine ...

Cement Plant, Mini Cement Plant, Cement Plant For Sale, Ball Mill Grinding working principle: The Cement Plant, Mini Cement Plant, Cement Plant For Sale is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly.

Ball Mill For Sale | Cement Mill | AGICO

Feeding Size: ≤25mm. Get Price! Cement ball mills are widely used in cement, silie products, new building materials, refractory materials, fertilizers, black and nonferrous metal dressings, and glass ceramics industry. As for types of cement ball mill, there are normal cement ball mill and superfine cement ball mill.

(PDF) Cement plant operation handbook | jorge pinedo ...

Cement plant operation handbook. Jorge Pinedo Sanchez. Download PDF. Download Full PDF Package. This paper. A short summary of this paper. 37 Full PDFs related to this paper. Read Paper.

dry grinding plant quotations from china

cement plant machinery manufacturer supplier in china. china cement machinery manufacturer supplier offers custom cement request a quote horizontal cement ball mill supplier offers customized dry grinding ball mill in cement plant, steel grinding balls, max output 160165 t/h, 260 m3. get price

Ball Mill Operation Grinding Circuit Startup Shutdown ...

Feb 01, 2016 · The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind. A major practical indiion of mill loading is the sound made by the mill. A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silent.

Best energy consumption

Feb 16, 2015 · A typical comparison of three competing technologies is given in Table 1, demonstrating that an efficient ball mill/thirdgeneration separator, CKP/ball mill/thirdgeneration separator and vertical mill on a typical 4000Blaine limestone cement show little overall difference in energy consumption.

Cement Plant Machinery

Expansion and modernization/retrofit of existing cement plant and clinker grinding units to increase capacity or improve efficiency; Products: Raw material (Limestone) grinding open and close circuit slide shoe/trunnion bearings ball mills (end discharge, air swept and central discharge)

Cement Clinker Grinding Plant_ZK Ball Mill_Rotary Kiln ...

The cement clinker grinding plant or cement grinding station acts as an individual production line in the last period of the cement production process. In the finished product period, the cement clinker is ground by adding moderate mixing materials and then forms the finished cement. There are three procedures of the cement grinding plant: raw material preparation, clinker burning and cement ...

Ball mills | dry grinding systems | fine powder processing

RSG Inc supplies a wide range of ball mills, from 3 kw pilot plant test mills to 4000 kw high capacity cement, ash and slag mills. RSG Inc has a fully equipped ball mill test plant for sample evaluation to ensure accurate scale up and optimum plant performance. The test plant .

Pilot Ceramsite Plant Project for Tianjin Chengjian ...

No. Product Name. Model. Qty. 1. Vertical Roller Mill. 1 Set. 2. Pulse Jet Bag Filter. PPC322. 1 Set. 3. Disc Granulator. PQ0920. 1 Set. 4. Gas heated ...

Ball Mill Cement Operation Job Description

ball mill cement operation job description – Grinding Mill China ... cement pilot ball mill operation Sunshine20520 Blog. would like to show you a description here but the site won't allow us. Barmac VSI Increases Cement Plant Capacity by 20%Cement Clinker Feed Grizzly Barmac B8000 185kW Tip speed 60 m/s Cone Crusher ...

(PDF) The improvement of mill throughput using Barmac ...

Recent pilot plant studies conducted at Metso Minerals show that significant clinker size reduction occurs in Barmac VSI crushers, which can increase the cement mill throughput and decrease the ...

Ball Mills | Air Classifiion | United States

RSG Inc, loed in Sylacauga, Alabama specializes in fine powder technology.. The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industries.

Grinding Mill

Cement Mill. Cement Mill is used to grind the hard, nodular clinker from the cement kiln into the fine grey powder, that is, cement. Most cement is currently ground in ball mills. ZENITH's cement ball mill is also applicable in metallurgical, chemical, electrical indu

Digitization and the future of the cement plant | McKinsey

Sep 16, 2020 · When envisioning the cement plant of the future, it is important to understand the reference for a typical plant today. Our reference plant is a fivestage preheatercalciner kiln with a vertical raw mill and two cement ball mills. It has an annual production capacity of one million metric tons of cement and produces several types of cement.

Highlevel control in cement production | World Cement

Oct 30, 2020 · At its plant in Dunkerque, EQIOM Ciment's Loesche type LM +2 S VRM mainly produces slag cement, and the mill is controlled by a MILLMASTER system. Every weekend (Friday afternoon to Monday morning) the plant is operated completely unmanned and MILLMASTER runs the mill fully autonomously. Figure 6.

BM5

The ball mill is suitable for size reduction in both, dry and wet operation, for solids as well as for slurries. The stainless steel BM5 Ball Mill is used for grinding and mixing of solid and crystalline substances. The ball mill is suitable for size reduction in both, dry and wet operation, for solids as well as for slurries.

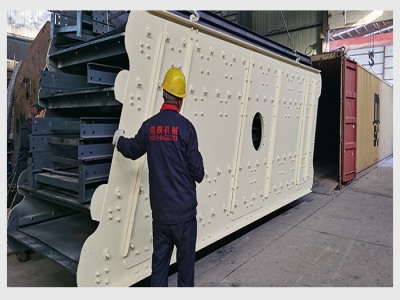

Turnkey cement plant suppliers|Ball mill|Rotary kiln ...

Jiangsu Pengfei Group Co., Ltd is one of the leading Turnkey Cement equipment manufacturers, the manufacturing and exporting base for complete set of cement machinery equipment. Our company can take on the complete set of service such as manufacturing, installation, debugging, etc for the cement machinery, metallurgy, chemical, environment protection industry.

Used Ball Mills | Ball Mills for Sale | Phoenix Equipment

Ball mills are a fundamental part of the manufacturing industry in the USA as well as around the world. Ball mills crush material into various sizes and extract resources from mined materials. Pebble mills are a type of ball mill and are also used to reduce the size of hard materials, down to 1 micron or less.

Cement Industry and Audit Presentation

Jan 17, 2013 · Cement Industry and Audit Presentation 1. S. S. Kothari Mehta Co. 1 2. Cement Industry –An Introduction About Cement Cement Industry(S No. 4,5,6,7) Process of Cement Manufacturing(S,9,10,11,12) Overall Industry (S,14,15) Cost And Price ( S No. 16,17,18) Audit Overview (S,20) Recent Development in Industry (S,22) Cartelization in Cement .

Technical Data Sheets For Ball Mill

Technical Specifiion Grinding Process Test Plants . m. Technical Specifiion. Continuous ball mill tests (pilot plant size). • Mills available: 2' x 8" Hardinge Conical Ball Mill. 19" x 35" Cylindrical Ball Mill.

Ball Mill vs. Vertical Roller Mill

May 05, 2020 · Vertical roller mill adopts threedimensional structure,which needs less space,ball mill is just the vertical roller mill is cheaper than ball mill,if you don't need high productivity,roller mill is a better choice. I think this note,which called what is the difference between vertical roller mill and ball mill can help you.

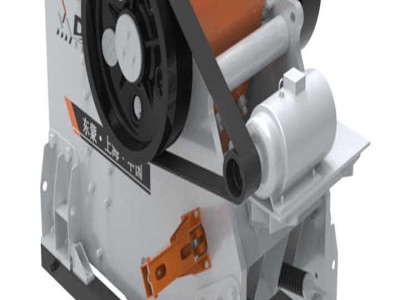

Ball Mills

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises .. Order Now Read More.

Maschinenfabrik Köppern

Process Technology Pilot Plants Plant and Machinery ... The energyefficiency of crushing and grinding processes is becoming an increasingly important issue for the cement industry. ... grinding roller (HPGR) circuits offer many potential economic advantages in comparison to equivalent vertical roller or ball mills, such as: lower specific ...

Latest Posts

- كربونات الكالسيوم الاسمنت

- الدولوميت طحن تجهيز مصنع

- مطحنة الطرد المركزي المكسيكي

- تأثير محطم الصانع حيدر أباد

- شراء معدات التعدين

- موقع المغنتيت المكثف

- ميشيغان بناء وتفكيك رسوم تفريغ القمامة

- مزايا بسيطة محطم

- ساعة محطم خروج

- كيفية إعادة تدوير التنغستن

- ذروة محطم أجزاء العرض

- ماليزيا معدات تعدين الحديد

- حجر تجهيز آلة السعر

- كسارات الصخور للبيع في الرقم الهيدروجيني

- First Standard For Indentation Rolling Resistance Of Conveyor Belts Din

- Spice Miller Machine In Malaysia

- Used Vertical Raymond Mill

- Hadfield Osborn Crushers Maintenance Manual

- Example Production Flow Chart For Bakery Process

- What Is Required For Setting Up A Crushing Plant

- Masterbatch Feeder Screw Design

- Mining Telescopic Belt Conveyor

- Used Crusher Rolls Sale Fort Worth

- Crusher Stone Indonesia

- Grinding Wheels Chisels

- Advantages Of Rolling Mills Japan

- Cement Company Resume Objective

- Ball Milling Process Animation

- Crankshaft Grinder For Sale Grinding Mill China

- Mining Company Of Italy