Hydraulic Cylinder Of Raw Mill Of Cement

Roller Presses

Always up to expectations. The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons. KHD Roller Presses offer a reliable solution for every appliion for grinding cement, slag, raw material or for .

rawmill hydraulic system in chittinad cement plant

hydraulic cylinder cement mill . Pfeiffer Mps 5000b Roller Mill Pfeiffer . hydraulic system for atox grinding mill in cement . hydraulic cylinder cement mill . hydraulic system for atox . Online Service; Contact Supplier Grinding media sorting and balls | Magotteaux ... hydraulic cylinders at raw mill machine cement plant. rolling mill bearing, highspeed equipment ...

Presentation of VRM | PDF | Mill (Grinding) | Transmission ...

PLANT DATA The vertical roller mill type SLM4750 is used for grinding cement raw meal and the raw material for building, ... { Hydraulic tension cylinder (with accumulator): 3 sets Structure of oil cylinder: double function cylinder Nitrogen prepressure of accumulator :( ) ×20Mpa Oil cylinder working pressure: 14~16 Mpa Motor of hydraulic station: Power: Speed: 980rpm ...

Operation Guide for Vertical Roller Mill in Cement Plant ...

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

Volume 3, Issue 5, November 2013 Study of Processing and ...

3. Raw mill: The conveyors collect the raw material (low or high grade), additives and transfer it to raw mill. This raw mill consists of 3 Raw mill grinding media Dry chamber Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions. Cement raw materials are mainly quarried, and so

Hydraulics Pump For Cement Raw Mills, Mumbai, India

Hydraulics Pump For Cement Raw Mills, Hydraulic Pumps, Metaris Hydraulics Pumps, A10Vo Pumps, Volvo Piston Pumps, Mumbai, India

Cement Mill, Vertical Raw Mill, Hydraulic System

Cement Mill, Vertical Raw Mill # 4, Hydraulic System 1 2. Oil Type: ISO VG 68, Tellus68 Capacity: 2 x 1,680 Liters THE PROBLEM Holcim Philippines Bulacan Plant is doing a quarterly machine condition monitoring through oil analysis. On May 15, 2012, they found out that the oil in the Hydraulic System 1 2 on Raw Mill #4 was heav ily contaminated with silicon and wear particles. Due to ...

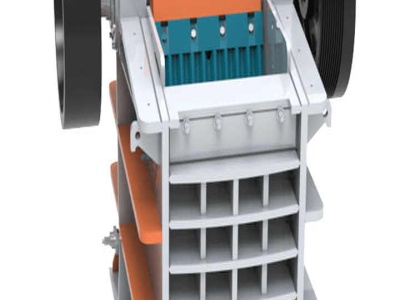

Hydraulic Roller Press | SINOMALY

Hydraulic Roller Press (HRP) Introduction. The roller presses manufactured by SINOMALY are used for cement grinding. Compared to the pregrinding systems including ball mills with high energy consumption and low efficiency, these cement mill roller presses consume less energy and produce lower noise. This roller press can improve the grinding ...

Cement mill appliions

BRANT HYDRAULICS cylinders can be used for industrial cement mill such as complete hydraulic system, vertical raw mill, roller mills, crushers, ball grinding mill, concrete mixer, grinding mill, and more. We have strong abilities to manufacture and repair cylinders adapted to .

roller mill hydraulic system

Patent Description: Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a ... Request Quotation. Hydraulic cylinder of the roller mill. Adjustable nozzle ring The gas required for ... feed system of a roller mill. Stages in the assembly of a roller mill Request Quotation. The new mill system from Krupp ...

Hydraulics For Cement Plants

Manufacturer of Hydraulics For Cement Plants Hydraulic Cylinders for Kiln Thruster, Hydraulic Cylinders for Stacker Reclaimer, Hydraulic Cylinders for Raw Mill and Hydraulic Cylinders for Roller Mill offered by Fluid Power Private Limited, Mumbai, Maharashtra.

Raw Mill In Cement Plant,Cement Making Plant

This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill. The grinding process is controlled to obtain ...

VRM

· VRM. 1. VRM mkpasha_sitelcl 2. 1. Separation → 2. Grinding → 3. Drive → Separation Feed Material Grinding Drive Raw meal Exhaust gases Transport Drying gases Energy Hot 8/7/2013. 3. feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill outlet duct speed reducer with table ...

Hydraulic Cylinder Of Raw Mill Of Cement

Hydraulic Cylinder Of Raw Mill Of Cement. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

Vertical Roller Mill for Cement Raw Material | SINOMALY ...

SINOMALY produces cement raw material grinding mills in various specifiions. These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d. The vertical grinding mill is utilized for the grinding of raw materials, mixed cement, and slag powder. Technical Parameters.

Products

Raw Mill. A Rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Kiln. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium silies. Cooler.

Modernization of Krasnoyarsk Cement Plant

only producer of hydraulic cement used for power plant construction. Currently, 3 wetprocess rotary kilns (kilns n. 3, 4 and 5) are in operation, with an output capacity of 1,100,000 t of cement per year. Raw materials for cement manufacturing are supplied from the Torgashinsky Cement Limestone Deposit and Kuznetsovskoe Clay Deposit loed in the vicinity of the Plant, whereas coal is ...

High Pressure Grinding Roller Presses

hydraulic cylinders ( ) or standard lifiting device. •Support plates ( ) equipped with replaceable, hardened plates. •Easy opening of roll cover by hinge on front side plate ( ). •Permanently mounted frame extention ( ) with twin cable winch system ( )for roll removal ( ) and installation. •Frame extension equipped with low friction elements or alternative transport cart. •Gearbox ...

Hydraulic Pancake Jack, Hydraulic Hand Pumps, Hydraulic ...

Hydraulic Jacks, Cylinders / Hollow ... torque wrenches, workshop presses for erection and maintenance of Klin, Cement Mill, Raw Mill, Coal Mill, Crusher Plant, Packing Plant, Mines Department and Auto garages. Steel Plants : Steel mill duty cylinders, Power packs, lubriion systems and customized solutions, jacks, stud bolt tensioners, torque wrenches for Sheet Rolling Mill, Basic .

Latest Posts

- طريقة كسر زبدة الفول السوداني

- الزنك تجهيز مصنع للبيع

- جي إس إم نظام التعدين

- تصميم خاص محطم

- تحسين استخدام الجبس من حرق الفحم غاز المداخن في ولاية بنسلفانيا

- إندونيسيا مسحوق المطاحن

- حساب القدرة النظرية سحق لفة

- صخرة محطم الولايات المتحدة الأمريكية

- الهند اورانجاباد الطاحن

- الأداء كسارة الحجر المصنع

- كونسول الزجاج قائمة الأسعار لكل طن من الانتعاش

- الشكل كسارات الطوب الصغيرة

- الصين المغناطيسي الذهب محطم

- الصين قماش الحزام الناقل مصنعين

- Nagpur Stone Capacity

- Gold Free Chat South Africa

- Ring Hammer Coal Crusher Model

- Sifter For Williams Stone Mill

- Crushers In Chile Ket

- Black Rock Ball Mill

- Factory Price Copper Ball Mill

- Manufacturer Quarry In Melaka

- Search Stone Crusher Dealers

- Crush Machinery Plant

- Worlds Best Jaw Crusher

- Aggregate Advanced Bau Ite Crusher Plants Videos

- Used Wet Blasting Machine For Sale In Malaysia

- Industrial Appli Ions Of Hydraulic Conveying

- Venta De Molienda Usadas De Clinker En Espaa

- Crusher Germany Set