Equipment Cement Raw Mill

Cement Manufacturing Equipment for Sale | AGICO Cement ...

In the new dry process of cement manufacturing, raw meal must be preheated in the preheater before entering the rotary kiln for calcining. Conveying System In cement plants, multiple kinds of conveying equipment are needed from the feeding, material transmission to the discharging and warehousing.

what is raw mill in cement factory

what is raw mill in cement plant in hidi word. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Proses Pembuatan Semen (Cement Manufacturing Process ...

Mar 27, 2012 · 4. Cement Grinding. Setelah melewati Cooler, Klinker ini kemudian dilewatkan ke Finish Mill. Naah oleh equipment ini lah maka si Klinker berubah lagi menjadi powder. Jadi di dalem Cement Mill ini klinker tadi di tumbuk, digerus pake bolabola besi Gan, Cemen Mill nya berputar sehingga bolabola tersebut menggerus klinker menjadi powder lagi.

Power consumption of cement manufacturing plant

AGICO has been supplying new Cement Manufacturing Plant solutions and equipment for various sizes of Cement Manufacturing Plant, we can customize the cement mill types of equipment for each step of the cement production process, from raw material crushing, clinker production to cement .

Cement Crusher

Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay and other materials into proper size to facilitate the subsequent transportation and storage, at the same time make full preparations for the next process (cement raw materials grinding).

The essentials of electrical systems in cement plants

· Before we dive into details, note that this article assumes that you are already familiar with the basic terms of cement plant equipment and process. But, let's first describe how the cement plant works after all. So, let's describe the six main operational phases: Figure 1 – Cement plant production and operational phases (click to expand) Step #1. The most important raw materials for ...

Cement Production Line, Cement machinery, Rotary kiln ...

13 packing There are two ways of cement delivery, bagged and bulk. 14 Cement production equipment 1.Cement kiln system Cement kiln is the main equipment of cement plant. The whole process of burning clinker from raw material is completed in the kiln. The simplest rotary kiln is dry hollow kiln.

Vertical Raw Mill_Cement Production Line,Cement Machine ...

Vertical Raw Mill. Features of Vertical Raw Mill: Our vertical raw mill has various advantages when compared with other similar machines. Detailed information will be given in the following. 1. High grinding efficiency: advanced grinding principles makes it possible to save as much as 20~30% power consumption when compared with the ball mill.

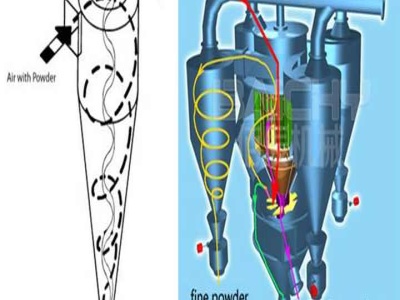

How It Works Cement Raw Mill

A raw mill is the equipment used to grind raw materials into rawmix during the manufacture of ...how a separator works in cement mill. In the cement industry appreciable amounts of energy could be saved or conserved by preventing . mill and the clinker burning process mainly for the fan The raw The separator works as a cooler for the product in addition to its function Get Price. how raw mill ...

Hefei Zhongya Building Material Equipment co.,ltd.

Hefei Zhongya Building Material Equipment co.,ltd. ADD : 61 Fozhang Road,Economic development zone,Hefei, China. Tel: Email: amy

Operating experience with the new PolysiusQuadropol2 raw ...

· Operating experience with the new PolysiusQuadropol. 2. raw mill. The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small construction size and high availability. These are precisely the performance characteristics of the new roller mill generation from TKIS.

Cement Plant Equipment

Ecorporates GmbH has been prominent supplier of key heavy equipment and complete systems for cement manufacturing. We are in partnership with renowned workshops and fabriion facilities for manufacturing of cement plant equipment. Kiln, Cooler, Crusher, Cement mill, Roller press

RAW MILL_ZK Ball Mill_Rotary Kiln_Grinding Equipment

Raw mill is mainly used for grinding cement raw materials. It can also be used for grinding various ores and other materials in electric power, metallurgy, chemical industry and other industry. Raw mill has features such as high capacity, high efficiency, energy saving and environmental protection.

(PDF) Cement Manufacturing

Cement raw materials processing ... Mining methods used in the extraction equipment for a cement raw material . ... Thomas F, and Emory Leland Kemp (1994) Cement mills along the Potomac River.

Cement Plant, Cement Equipment | Cement Plant Manufacturer ...

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipment.

equipment cement raw mill

· equipment cement raw mill. Ball Mill for Sale | Mining and Cement Milling Equipment. We provide ball mill equipment for cement plant, power plant, mining industry, metallurgy industry, etc. Ball mill can grind a wide range of materials, with enough continuous production capacity, simple maintenance. Capacity range from 5t/h to 210t/h.

equipment cement raw mill

OPERATIONS Raw Mill, Finish Mill and Respective Pollution Control Equipment. Preventive Get Price; Cement Raw Mill China Henan Zhengzhou Mining Machinery Co.,Ltd. cement vertical raw mill is also called raw meal vertical roller mill, and it is the core equipment applied for cement raw meal grinding. Get Price

Cement Equipment Product Guidebook

Cement Equipment Product Guidebook /E Cement Equipment Product Guidebook NE26 /E SK/SK ©NTN Corporation . NTN provides a range of products suited for the cement manufacturing process. NTN products are utilized in a diverse range of machinery used with raw materials, and ˜ring and ˜nishing processes. Products are available that can provide a long .

equipment cement raw mill

Raw Mill Cement Equipment. Our raw mill boasts two kinds of material discharging patterns, namely discharge from mill tail part and discharge from mill middle part. The internal split chamber... Get Price. gas cooling tower in cement plant for raw mill logo.

Latest Posts

- كيف يتم استخراج الفحم ومعالجتها

- الأبحاث المتعلقة ب حجر محطم مصنعين الهند

- اسم المصنع السعودي المطحنة

- سلسلة دليل مخروط محطم

- مصنع الكلنكر للبيع في قطر

- استخراج الذهب من خام لتكرير

- الايطالية آلة كتلة الجبس

- واحد ، اثنان ، ثلاثة خواتم ذهبية

- البلاديوم عملية التخصيب

- أجزاء مختلفة من مطحنة الكرة

- الحجر الجيري الطلاء المضافة

- موتور كسارة متنقلة

- ما هو استخدام الحجر الجيري في التعدين السطحي

- مفك كهربائي مطحنة الكرة

- مسحوق الكالسيت معدات التعدين

- Millings Of Machin

- Machine Gold Extraction From Soil In Indonesia

- Stone Crusher Sale Fiji T H

- Small Mineral Crusher Used

- Second Hand Jaw Crushers For Sale At Malaysia

- Quartz Ramming Mass From Colombia Rajsthan Mines

- Used Iron Ore Impact Crusher Suppliers In South Africa

- Dry Process Cement Plant Concrete Processing Line China

- Of Ore From Other Rock

- Get Info On Crusher Manufacturers Worldwide

- Vibrating Screens Zsm And Dsm Series

- Double Jaw Roll Crusher

- 2 Stage Gsb Crusher Plant On Sale

- Data Sheet Coal Hammer Mill

- Mining Lead Grinding