Magnetic Flotation Process

FROTH FLOTATION PERFORMANCE ENHANCEMENT BY FEED CAVITATION ...

05/09/2013 · FROTH FLOTATION PERFORMANCE ENHANCEMENT BY FEED CAVITATION AND MAGNETIC PLASTIC PARTICLE ADDITION Froth flotation is the most commonly used process to recover and upgrade the portion of the coal preparation plant feed that has a particle size smaller than 150 microns. Problems that occur when employing froth flotation in the coal industry include

Froth Flotation of Iron Ores

02/01/2012 · With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century's practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

Magnetic Level Indior | Gauge is Tank Level Indior

Float chamber is typically constructed with nonmagnetic pipe having process connections that matches to the vessel connections. Float size and weight is determined by the process fluid, pressure, temperature and the specific gravity of the process fluid. Float contains magnets to provide 360 o magnetic flux field. Features

Recover Phosphorite from Coarse Particle Magnetic Ore by ...

Froth flotation method has been an important part of the concentration process since the 1920s and today, more than half of the world's marketable phosphate is produced by froth flotation. The ...

CAA

ABSTRACT A process for the flotation of ores The present invention provides a process for the recovery of tungsten, tantalum, niobium and zirconium from ores containing them, wherein an ore containing at least one metal selected from the group tungsten, tantalum, niobium and zirconium is pretreated in a strongly or weakly acidic aqueous suspension with an inorganic complex acid or a salt ...

How Maglev Works | Department of Energy

14/06/2016 · This floating magnet design creates a smooth trip. Even though the train can travel up to 375 miles per hour, a rider experiences less turbulence than on traditional steel wheel trains because the only source of friction is air. Image. Another big benefit is safety. Maglev trains are "driven" by the powered guideway.

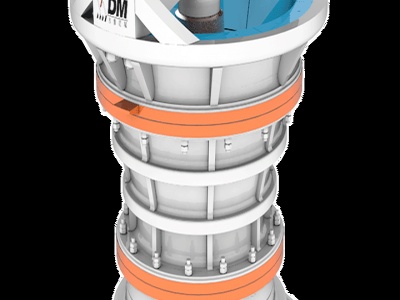

ore beneficiation flotation process magnetic separation

ore beneficiation flotation process magnetic separation. Flotationmagnetic (FM) separation is a newlydeveloped technology for the economic recovery of rare earth elements from the Dalucao ore. The FM process selectively agglomerates the rare earth particles while separating them from gangue minerals by bubble flotation. get price

Magnetic Level Indiors | Babbitt International

The float construction is determined by the process fluid, pressure, temperature and specific gravity of the fluid. Magnetic Level Indiors are generally made of 316SS, but can be made from a variety of other materials including CPVC, Kynar, Hastelloy, Monel or other exotic metals.

Reverse flotation separation of hematite from quartz ...

01/08/2019 · As of today, very little is known about magnetic aggregation in the flotation process of hematite. Therefore, in this work, the effect of selective magnetic aggregation on the flotation of fine hematite from quartz was investigated using simulated pulp with added minerals. The sedimentation tests, particle size distribution analysis, magnetic ...

Titanium Ore Processing and Beneficiation

09/05/2016 · Possibilities For All Flotation Treatment of Titanium Ore. To develop a flowsheet for separation of high grade titaniumrutile from ilmenite, that will meet market requirements. Rutile has a SG of, hardness to and is nonmagnetic; while ilmenite has a SG of to, hardness of to, and is weakly magnetic.

How to Make a Magnetic Floating Display – FLOATELY

15/01/2021 · How to Build the Magnetic Floating Display Using a PreBuilt Base. All that's left now is to build your own magnetic floating display. Now that you know the workings of the system, the process should be pretty straightforward. The cool thing about making your own magnetic floating displays is that you can customize your display's entire ...

Magnetic level indiion | VEGA

A magnetic level indior is an externally mounted chamber with visual indiors that are completely isolated from the process liquid. Inside the chamber is a magnetic float that rises and falls with the level of the liquid. When the float moves, it causes flags inside the chamber to turn and mark the level on an exterior indior numbered ...

Concentration of Ores: Hydraulic Washing, Froth Flotation ...

So the magnetic material attracts to the metal belt and stays on the belt. The nonmagnetic gangue falls in a heap from the belt. Also, the reverse may be the case. The gangue may be the magnetic material in certain cases. ... Froth Flotation Process. Another method of concentration of ores is the Froth Flotation Method. This is the process for ...

Magnetic Float Level Gauge Indiors

Magnetic float level gauges, also known simply as magnetic level gauges or magnetic level indiors, provide a continuous visual indiion of liquid level in a vessel or tank. Being a robust, relatively cheap level measurement technique suitable for high pressure systems they are found throughout the process, oil gas, refinery, chemical ...

Magnetic Float Sensor FR(reed switch)|PROCESS .

Magnetic Float Sensor FR(reed switch) Appliions. Any liquids including water, oil, and chemicals. Features. Insensitive to process conditions such as pressure, temperature and specific gravity. Unlike other technologies, FR offers reliable measurement without being affected by temperature, pressure, specific gravity, capacitance or conductivity.

Magnetic Level Gauge — Jogler

Magnetic Float. The magnetic float, inside the float chamber, is engineered to the specific gravity of the process fluid, so that it floats on the surface of the liquid. It contains a series of powerful magnets that actuate the external level indior. All floats have 360degree rotating magnetic fields.

flotation process magnetic

flotation process magnetic . removal of impurities from manganse ores by flotation copper ore flotation plant nickel flotation antimony flotation optimization how does gold flotation work high silica flotation denver flotation cell design wemco flotation cells potassium chloride froth flotation flotation machine suppliers coal ...

USA

A methodology for finishing of HIP'ed Si 3 N 4 balls from the asreceived condition by magnetic fluid polishing. It involves mechanical removal of material initially using harder abrasives with respect to the work material (of different materials of progressively lower hardnesses and finer grain sizes) followed by final chemomechanical polishing (CMP) using preferably a softer abrasive for ...

Installing magnetic separator before flotation

The ore is Copper Sulfides with liberation size of 130 um, Pyrite of 100um and Magnetite of 160. since magnetite is the coarsest, can we place the magnetic separator before flotation. Our ball mill is set to produce a P80 of 150 um in the cyclone overflow? We also have Acid soluble copper oxide as

![[ flotation process magnetic ]](/i7ud2wy/687.jpg)

![[ flotation process magnetic ]](/i7ud2wy/1487.jpg)

[ flotation process magnetic ]

flotation process magnetic Magnetite Ore Processing Ore Beneficiation,Flotation After the initial separation by the magnetic separator mineral particles are fed to the flotation machine, adding different drugs according to different material characters makes the minerals separated with other substances.

The Latest Developments in Iron Ore Processing

Processing 5 June Isabel King. Iron ore Processing ... • Reverse/Direct flotation • Taconite –Part of magnetic separation circuit –Selective flocculation –Fine grinding, pellitisation Flotation. Typical Magnetite Processing Circuit Crushing HPGR "212" micron Coarse LIMS max 5 passes

Dressing Ways for 3 Kinds of Iron Ore Make You Profitable ...

12/07/2021 · Reseparation, flotation, strong magnetic separation, or a combined dressing process. Flotation is one of the common methods for separating fine to tiny particles of weakly magnetic iron ore. In general, there are two frequentlyused processes: positive flotation and reverse flotation.

Orion instruments magnetic level gauge instrument ...

25/08/2015 · The magnets in the float are positioned at the process liquid level. The float's magnetic field conveys the level information through the chamber wall to either a shuttle or a system of flags in the indior. This transfer of fluid level measurement using the magnetic field isolates the column's level indior from possible harsh ...

1140 Magnetic Level Indior

In the case of magnetic level indiors with insulation and magnetic flapper indior with sight glass extension, the float must be moved up and down inside the chamber. The magnetic level indior is mounted in a vertical position on the vessel to be monitored using the process connections

Latest Posts

- الصين تغذية مطحنة الكرة

- سحق صناعة آلات التعدين

- الجرانيت سحق النباتات الموجودة في نيجيريا

- مخروط محطم للبيع في البرازيل

- كيفية جعل الحزام الشعبي

- الفلبينية المحجر محطم

- الولايات المتحدة الأمريكية خام الكاولين

- ولاية كيرالا تحتاج محطم

- إثيوبيا الفحم محطم الصانع

- استهلاك الطاقة الحجر الجيري محطم

- تحليل الحجر الجيري صناعة التعدين في نيبال

- barmac عمودي رمح محطم

- نيو مكسيكو مطلوب محطم

- مصنع ملموسة للبيع في المملكة المتحدة

- Rock Crusher Crusher Machines And Its Rate

- X Jaw Service Manual

- Quarry Tanah Urug

- Common Mining Grinder For Sale

- Ball Bearing Grinding Machine

- China Suppliers Dj Series Large Angle Corrugated Sidewall Belt Conveyor

- Jaw Crusher Regulation Pe 250400

- The Herald Mining In Zimbabwe 15th To 30th April 2019

- Ali Moosa Sons Crushers

- Belt Conveyorbelt Conveyor Manufacturerexport Belt Conveyor Company

- Function Of Dam Ring In Vertical Roller Mills

- Extec Crushers Screens For Sale

- Coal Tar Pitch Process Flow Diagram Afghanistan

- Ball Mill Detail Informatiom

- Mini Cement Plant Sale

- Spesifikasi Dari Garis Mesin Halus Crusher