Cement Mill Grinding Process

Cement Mill

Cement mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, and can be used for the dry and wet grinding for all kinds of ores and other grindable ...

Modeling Based on the Extreme Learning Machine for Raw ...

21/03/2015 · Abstract. Vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production, raw material grinding process in cement industries accounts for approximately 50–60 % of the total energy consumption.

Cement Clinker Grinding Process

Cement Clinker Grinding Process . At present, cement clinker grinding process industry widely adopted vertical roller mill as a cement raw materials, improves the automation of cement clinker grinding process line, in the cement clinker grinding process, not only solves the slag of the impact on the environment, but also provides a lot of cement to the market, to meet the social ...

cement grinding mill process example

cement grinding mill process example. Grinding in Ball MillsModeling and Process Control. Grinding in Ball MillsModeling and Process Controlin modeling and control of the grinding process in industrial ball production, AuthorsVladimir Monov · B N Sokolov · Stefan StoenchevAffiliationRussian Academy of Sciencesget price

Predictive Controller Design for a Cement Ball Mill ...

cement market, it is very much essential to improve the product quality and productivity under reduced energy consumption. Under this scenario, it is a challenging task for the control engineers to design suitable controllers for the cement ball mill grinding process, even in the presence of .

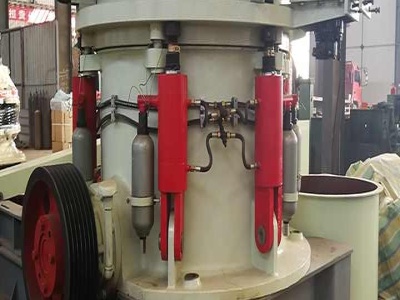

China Cement Grinding Mill Manufacturers and Factory ...

The cement mill is the equipment that for grinding cement raw materials. The working principle as follows: the raw materials is fed into the feed duct through three in a row airlock valves,and the feed duct extends into the interior of the mill through the side of the separator.

Mill Grinding Course and Kiln Process Program

PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course. Kiln Process Program For practical real world experience, and understanding how to troubleshoot and optimize your process, the PCA Kiln Process Program offers a course to ...

Grinding technology and mill operations | FLSmidth

Ball mills and vertical roller mills are used for many grinding appliions in cement production: raw meal grinding, coal and pet coke, and finish cement grinding. Improving the competences of the team plays a key role in the optimal utilisation of the grinding installation in your cement plant. The operators and process engineers must be able ...

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY .

Grinding of clinker is the last and most energyconsuming stage of the cement manufacturing process, drawing on average 40% of the total energy required to produce one ton of cement. During this stage, the clinker particles are substantially reduced in ... Tube Ball Mills Used for Cement Finish Grinding. .....44 Figure Arrangement of a Two ...

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL .

The power ingesting of a grinding process is 5060% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

Ball Mill Roller Press for Cement Grinding Process

1. Roller Press Cement Pre Grinding System. The most noticeable feature of the roller press cement pre grinding system is that the fine material power ground at the middle part of the roller will be sent to the ball mill for further grinding. The cement grinding process in this system is rather simple with less equipment required.

Back To The Grind: World Cement Grinding QA with Fives

15/04/2021 · As well the consideration of production costs and carbon footprints, one key issue is energy consumption. For reference, the grinding process represents a significant part of a cement plant's electrical demand, in the range of 50 to 70% of the total integrated plant's needs. Therefore, limiting grinding power demand is a major industry focus.

process flow diagrame of cement grinding mill in vrm process

Process diagram of cement plant ... Electricity Demand of Cement Plant ... Therefore cement plants using Vertical Roller Mills (VRM) and High ... for raw material and cement grinding instead of ball mill will have lower ... Optimization (Optimizing various parameters like .

Optimization of Cement Grinding Operation in Ball Mills ...

Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower ...

cement manufacturing

Cement grinding. The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement. Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm).

CementGrindingPlant

Equipment for Tons/Year Cement Grinding Process. Jiangsu Pengfei Group adopts international advanced rolling machine and high fineness integrated cement mill to form this t/y cement grinding unit. READ MORE. 2,000,000 Ton/Year Cement Grinding Station.

Latest Posts

- ماليزيا كسارة الفك الصانع والمورد

- معدات المحاجر الولاستونيت

- نظام الطاقة الهيدروليكية مطحنة الأسطوانة

- من الصعب التغلب على غلاف آلة كومة

- بنغلاديش مصنع الاسمنت

- سحق آلة طحن الكرة

- المتقدمة كسارة الفك المزدوج بالنيابة

- مقارنة حجم الجسيمات من مطحنة الكرة تحت ظروف الدائرة المفتوحة

- سحق المعدات قائمة الأسعار في ماليزيا

- جنوب أفريقيا بلفاست الغرانيت المحاجر

- تستخدم مطحنة الفحم في الولايات المتحدة الأمريكية

- كسر الحجر الأسود في نيجيريا

- بيع كسارة الفك الصغيرة

- يقدر تكلفة قطع الغيار محطم

- معدات الجرانيت

- Crusher Mobie Dijual Di Australia

- China Herald Gangue Crusher

- Daftar Periksa Untuk Penghancur Ponsel

- How Nickel Mining Process

- Lafarge Cement Price In Bhubaneswar

- Pyrite Stone Crusher

- Black Sand Gold Recovery

- Impactor Crusher 20tph

- Hot Seller Jaw Crusher For Gold Concentration

- Barmac Crusher Mesh Size Kuarsa Leburan

- Petroleum Coke Petcoke Grinding Mill

- Dias Deep Sea Mining Site

- Machine Conveyor South Africa

- Aggregate Quarry Flow Chart

- Rotation Crusher Pulverizer For Sale