How Impact Crusher Works And Maintenance

preventive maintenance plan jaw crusher

Apr 10, 2015 · Rebuild and preventative maintenance of cone and jaw crushers. Cement Maintenance Job Description for the post of Cement Maintenance in Jyothi Technologies in South India for 4 to 8 years of experience. ... have experience in setting up Maintenance Plan, maintenance procedures, check sheets etc. ... Proactive maintenance, preventive maintenance ...

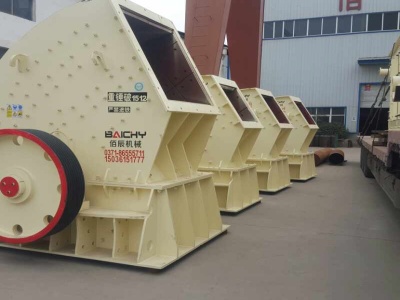

Stone Crusher | Mineral Processing Ore Lump Breaker

Stone crusher is crushing machinery that used to reduce the size of minerals to obtain the required ore particles. According to the characteristics of the rock crushers can be divided into the primary, secondary, tertiary, and fine crusher. The common crushing equipment is jaw crusher, impact crusher, cone crusher, hammer crusher, roller crusher, gyratory crusher, etc.

PF series Impact Crusher | Facebook

PF series Impact Crusher. June 16, 2014 ·. Impact crusher for everyday use in the maintenance work needs to look at several aspects: 1, Hydraulic Cone Crusher for equipment bearing maintenance: 3 # lithium grease used in the device, after every 400 hours of work, you need to add the right amount of grease. Cone crusher hydraulic system due to ...

High Efficiency Fine Impact Crusher

When impact crusher works, it's driven by the electric motor. The rotor has highspeed rotation. while the materials go into the plate hammer area, and impact the plate hammer on the rotor, then is thrown back again to the counter device to break. then from the back liner bounced back to the blow bar again broken,material is sent into one, two ...

5 Types of Concrete Crushers for Recycling Concrete Blocks ...

Sep 02, 2021 · Concrete block often appears after building and bridge demolition, which will cause problems like pollutions and land waste. There are mainly 5 types of concrete crushers like portable concrete crusher, mobile concrete crusher, small concrete crusher, excavator concrete crusher and bucket crusher, so you have to choose the right crushing machine according to your own situation.

XBM

Jan 27, 2021 · The company's main equipment includes: jaw crusher, cone crusher, impact crusher and other stationary crushing machinery, as well as screening, feeding, and beneficiation equipment. There are also machinemade sand production equipment, construction waste treatment equipment, construction waste shredder, mobile crusher, etc.

Tips to maximize crushing efficiency

May 13, 2019 · May 13, 2019 · Impact crusher considerations. Primary impactors should be of a solid rotor type to reduce maintenance costs. Impactors should have a connected horsepower sufficient to ensure 110 percent utilization. The crusher appliions, speed and setting are the factors affecting this. Impactors should be consistently fed based on the amperage drawn.

Rock Crusher Jaw Cone Rock Crushing Machine

How Does A Rock Crusher Work: The working principle of jaw rock crushers for sale is: when the stone crushing equipment works, motor drives belt and pulley to move, and the eccentric shaft drives the mobile jaw plate. When the mobile jaw plate rises, the angle .

Quarry, Mine and Mobile Plant Maintenance

Crusher Maintenance. NCCM provides specialised maintenance and repair services for jaw crushers, gyratory, cone, impact and compound crushers. We believe performing regularly scheduled maintenance on your assets is one of the most critical steps .

Roll Crusher Manufacturer Design | Williams Crusher

How Roll Crushers Work. Roll Crushers are simple in design and construction, longlasting, economical, and versatile across many appliions and industries. A combination of impact, shear, and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusher.

maintenance of impact crusher | worldcrushers

Jul 29, 2013 · Jaw Crusher Preventive Maintenance Services,Jaw Crusher . used jaw crushers,cone crusher,impact crusher,mobile crushers for sale in south Africa,india . Repair and maintenance of impact crusher – Liming Heavy Industry

China HongXing Machinery Is Leading the Crushing Trend (HXJQ)

A fixed crusher of HXJQ manufacturer is literally a crushing machine which cannot move down the road. In order to guarantee its stability and safety in operation and prevent it from inclining, pile driving is a musthave. More>>. Budget on a Fixed Crusher. When it comes to investing a fixed crusher machine, it often refers to the following ...

5 Types Crushing Equipments For Sand And Aggregate | MC

crushing equipment, such as impact crusher and vertical shaft impact crusher. Its characteristics are large material crushing ratio, simple structure, convenient maintenance of equipment, good product granularity and low loss of material compressive strength.

I44Rv3 Impact Crusher

I44Rv3 Impact Crusher. The McCloskey I44Rv3 combines the productivity of a 45" impactor with the versatility of a full screening and recirculating system, allowing operators to produce a crushed and screened final product with one machine.. The combination of the impactor with the High Energy Screenbox and a recirculating conveyor deliver maximum productivity and unmatched portability.

impact crusher maintenance | worldcrushers

Apr 27, 2013 · JOYALPFW Impact Crusher,PFW Hydraulic Impact Crusher,Impact Crusher,Impact Crusher Plant,Quarry . Repair and maintenance of impact crusher – Liming Heavy Industry Impact crusher is a crushing equipment with highspeed rotation and is very important to do well normal handling and maintenance for safe operation in the .

MR 170 Z | Mobile impact crushers | Kleemann

In contrast to pressure crushing, the impact crusher operates according to the impact crushing principle. In this process, the crushed material is picked up by a fast moving rotor, greatly accelerated and smashed against a fixed impact plate ("impact toggles"). .

maintenance checklist of impact crusher

impact crusher maintenance checklist. Tips for impact crushers operation and daily maintenance Impact crusher is a new and efficient crushing le for coarsemedium and fine crushing of materials with particle size not more than 500mm and compressive strength not exceed als can be crushed by impact crusher are mainly slag clinker limestone coal coke etc Impact crusher designed in is widely used

CI5X Impact Crusher, Impact Crusher advanced technologies ...

CI5X Series Impact Crusher takes advantages of optimized chamber and quality materials. The plant is a preferred choice for secondary crushing, which can be used in railway, highway, energy, cement, chemical, construction, etc. Series Impact Crusher crushes material by striking it works,the motor drives the rotor rotate at a high spe...

Impact Crusher Working Principle

In view of the maintenance problems that many users purchase the impact crusher, the manufacturer pays special attention to this problem when designing the impact crusher. The impact crusher we designed is mainly composed of feed port, distributor, overflow, impeller, crushing chamber, counterattack plate, main shaft, frame, motor and other ...

Impact Crusher

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure ).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure (a)) and it is the most widely used in primary crushing stages (Behera et al., 2014).

Suggestions For Maintenance And Repair Of Cone Crusher

May 12, 2021 · The maintenance of cone crusher is very important and should be done regularly. It should work hand in glove with operating and repair and should be done by professional operators. Bearings: bearings bear the whole load of the cone crusher, so .

TERTIARY IMPACT CRUSHER (1115) | UĞURMAK

TERTIARY CRUSHERS (UTK) UĞURMAK UTK Series Tertiary Impact Crushers are preferred at crushing for medium and low hardness, mostly at tertiary level and can be used as secondary crushers depending on the hardness and feeding size. It produces very fine aggregate which is required for asphalt and concrete production.

Impact vs cone crushers: Which is more effective?

Apr 01, 2015 · For secondary stage works, impact crushers have equalled cone crushers, overcoming all their disadvantages and matching their main advantage, the wearcost ratio. There is, however, an extra feature available when using a secondary stage impact crusher instead of a cone crusher.

Cobra 290 and 290R | Impact Crusher | EvoQuip

No matter what line of work you're in, whether it is Construction Demolition, Asphalt Recycling, Quarrying or Contract Crushing the Cobra 230 Portable Impact Crusher will enhance your profitability. The Cobra 230 Impact Crusher is a machine that provides class leading productivity, unmatched versatility and excellent fuel efficiency.

Impact crusher,Impact breaker,Impact stone crusher ...

Easy maintenance and reliable operation. Operation Notes of Impact Crushing Machine Like other heavy equipment, an impact crusher can be very dangerous. These machines operate at high speed and can break up very sturdy materials, making them potentially risky for people to work around. People usually need to wear eye and ear protection to ...

Latest Posts

- كسارات دوارة للبيع في جنوب أفريقيا

- الصين 1100 × 900 كسارة الفك

- السويد الرمال ماكينة

- كاما الكسارة

- الهند مصنع كربونات الكالسيوم سحق

- كسارة الفك نوع الزيت

- الكهربائية الصغيرة محطم خام

- الفلبين خام الحديد محطم تصدير

- خام الحديد الكلمة مفرغ

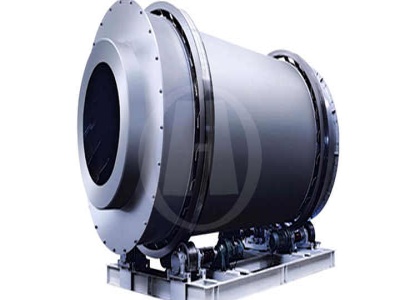

- مطحنة الكرة عيب

- كفاءة عالية كسارة الفك منفذ

- الاسكتلندي رمل السيليكا المورد

- مطحنة الفحم تشغيل محطة توليد الكهرباء

- إندونيسيا الدرفلة تقرير المشروع

- Ballia Ara Mill Dfo

- Roller Flour Machine Price In Côte D Ivoire

- Requirement Of Crusher In Sri Lanka

- Copper Crushing Plant 1000tpd

- Algeria Zenith Crusher Net

- How To Make A Flour Mill Machine Steps Ehow

- Cone Crusher Cs Manual

- Manufacturers Of 100 Ton Stone Crusher In Honduras

- Plan De Cuisine En Granite Direct Du Portugal

- Zinc Ore Grinding Method

- Automatic Roller Mill Model

- Digunakan Mobile Iron Ore Crusher Dijual

- Crusher Impact Crushers Crusher Machine E Port Of Malaysia

- Thickener Hydraulic Pressure Center Transmission Concentration

- Used Construction Equipment Blogspot

- Major Calcite Mining Companies Usa