Iron Ore Waste As Coarse Aggregate

use of iron ore as coarse aggregate in concrete making

Feb 05, 2015· The successful utilization of iron ore tailing (IOT) as fine aggregate would turn this waste material into valuable resources, reduction in the strain on the supply of natural sand, and economy in concrete production. World production averages one billion metric tons of raw ore annually. Mechanical Properties of Concrete Using Steel Slag . coarse aggregates in concrete has no ...

USING IRON ORE WASTE AS AGGREGATE IN MAKING K. 300 .

USING IRON ORE WASTE AS AGGREGATE IN MAKING K. 300 QUALITY CONCRETE Rajiman*1, Muhammad Amin2, Harjianto Setiaji3 1Bandar Lampung University 2Mineral Technology Research of Indonesian Institute of Sciences –LIPI 3Sang Bumi Ruwa Jurai University Korespondensi: rajimanmt ABSTRACT The main component of concrete is cement, water, and .

iron ore waste coarseaggregate

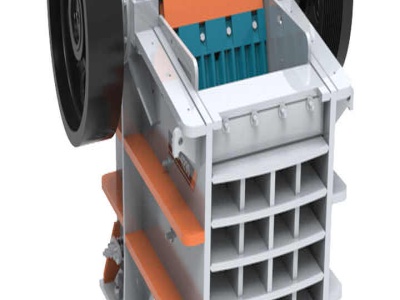

iron ore waste coarseaggregate. Waste glass coarse aggregate concrete recyclers and they are mainly used to crush coarse minerals like gold and copper ore metals like steel and iron glass coal asphalt gravel concrete etc with more than 2500 case sites the scientific management method the refined manufacturing process and the innovative manufacturing concept

iron ore waste utilistation

iron ore waste as coarse aggregate in concrete. The successful utilization of iron ore tailing (IOT) as fine aggregate would turn this waste material into valuable resources, reduction in the strain on supply of natural sand and economy in concrete production. Objective Partial replacement of iron ore . Effective utilization of iron ore slime, a mining waste as ... Iron ore slime is the ...

Utilisation of iron ore tailings as aggregates in concrete

The iron ore tailings aggregates concrete exhibited a good mechanical strength and even in the case of compressive strength, there was an improvement of % over conventional aggregates concrete. The indirect tensile strength did not improve against the control mix due high content of fines in the tailings aggregates but showed % improvement compared with the previous study where the ...

An Experimental Study on Partial Replacement of Coarse ...

Coarse Aggregate by Iron Slag with Polypropylyne Fiber P. Vignesh Kumar1, ... Abstract: Iron slag an industrial waste byproduct of steel industry. Basically it consists aggregates which are bonded together cement and water. Old scrap is collected after a use cycle, either separately or mixed, and it is often contaminated a certain degree, to depending highly on its origin and the collection ...

(PDF) UTILIZATION OF IRON ORE TAILINGS AS REPLACEMENT TO ...

In future, the proportion of iron ore wastes generated is likely to increase due to higher demand General for iron ore as a number of steel plants have been planned An attempt is made with Iron Ore Tailings as a partial for future in many parts of the country. In order to reduce replacement of fine aggregate in the concrete. The main aim the adverse impact of indiscriminate mining of ...

(PDF) A study on suitability of iron ore overburden waste ...

The aim of this study is to evaluate the suitability of iron ore waste as partial replacement of coarse aggregates in concrete with reference to the conventional materials. Physicochemical ...

Use of Blast Furnace Slag Aggregate in Concrete

the other comprising granite stone as coarse aggregates. The compressive strength of BFS aggregate concrete is higher than that of the stone aggregate concrete at the age of 90 days. Manufacturing and Types In the production of iron, iron ore, iron scrap, and fluxes (limestone and/or dolomite) are charged into a blast furnace along

coarse aggregate mills

iron ore waste as coarse aggregate in concrete | Solution, aggregate crushing plant,Coarse Aggregate Mills, Posts Related to iron ore waste as coarse aggregate in concrete ceramic waste as aggregate replacement... Read More. Pelletized Cut Rubber: An Alternative Coarse Aggregate, Pelletized Cut Rubber: An Alternative Coarse Aggregate for, natural coarse aggregate, fuel for .

Experimental Study on Iron Ore Tailings and Bottom Ash as ...

the proportion of iron ore wastes generated is likely to increase due to higher demand for iron ore. Moreover, dumping causes loss of valuable land. problems. IOT is waste produced during iron ore produc Iron Ore Tailing of fine aggregate with IOT and bottom ash helps to effectively In India, over 70% of electricity generated is by combustion of fossil fuels, out of which approximately ...

Cost Effective Concrete by Using Mangalore Tile Wastages ...

Iron ore dust can be defined as residue, tailing or waste material which is left after the extraction and processing of iron ore in the mines to form fine particles less than Usually, Iron ore dust is treated as a complete waste, and used to fill the low lying areas. Use of Iron ore dust as an alternative to normal aggregates in concrete M. Nadeem et al [3] draws serious attention of ...

Effect of Iron Ore Tailing on the Properties of Concrete

Table 2 Chemical Composition of Itakpe Iron Ore tailing (IOT) Mineral Fe 2O3 SiO 2 CaO Al 2O3 MgO TiO 2 Composition (%) Figure 2. Particle size curve (IOT) Coarse aggregates Natural gravel aggregates having bulk density of 1600kg/m3. The specific gravity of coarse aggregate is

Iron Ore Coarse Fines Sizes

Iron Ore Coarse Fines Sizes. Difference between iron ore fines and iron ore pellets Iron ore lumps size 10 40mm Iron ore fines Granular size of up to 10 mm for up to 90 of the cargo While lumps are crushed to 5 20mm size in crusher normally 30 fines waste will be generated.

Materials | Free FullText | Sustainable Appliions for ...

Gayana and Chandar proposed that some waste materials, such as iron ore tailings, recycled concrete aggregate, glass, plastics, ... Vijayaraghavan et al. investigated the effect of using alternatives for both fine and coarse aggregates with copper slag, iron slag, and recycled concrete aggregate with various proportions of mix. Based on the characteristics of coarse aggregates and the ...

Experimental Study on the Properties of Concrete Mixed ...

· As shown in Figure 3, the slumps and liquidity of concrete mixed with iron ore tailings decreased compared with that of normal concrete under the same condition (water, mixture ratio, admixture, etc.).This phenomenon arises because the particles of iron ore tailings are rough and occluded with coarse aggregate, so cohesion increases significantly in the tailing mixes.

Iron Mines Disposal Of The Waste

ore mining machine for mine tailing disposal. Management of Tailings and Waste Rock in Mining Activities Apr 4, 2010 . Typically the mine and the mineral processing plant are designed to extract as much co disposal of iron ore tailings and waste rock . Live Chat. Get Detail; Iron Ore Waste As Coarse Aggregate In Concrete

Aggregate | What Is Aggregate | 17 Types Of Aggregates ...

These aggregates are made from different waste materials. Artificial aggregate are sometimes manufactured for severing special work: – To make lightweight concrete: burned clays, artificial cinders, foamed slag, expanded shale's and slate, sintered fly ash exfoliated vermiculite is used. To make highdensity concrete: steel rivet punching and iron ore (Magnetite) have been used. 4 ...

iron ore as fine aggregate

iron ore waste as coarse aggregate. Iron Ore Coarse Size. of Iron Ore tailings which remains as overburden In future the proportion of iron ore wastes generated is likely to increase due to higher demand for iron ore Moreover dumping causes loss of valuable land problems IOT is waste produced during iron ore produc Fig 1 Iron Ore Tailing of fine aggregate with IOT and bottom ash helps to ...

coarse iron ore

Iron ore particles were produced through coarse crushing of raw iron ore sample to a certain size of below 50 mm and then classified to various size fractions by using a set of sieves. 500 coarse iron ore particles were selected as the study objects, which were divided into five size fractions of − + 25, − 25 + 20, − 20 + 15, − 15 + 10, and − 10 + 6 mm, as shown in Fig. 1. 100 ...

iron ore waste as coarse aggregate in concrete

The ingredients of concrete are coarse aggregate, fine aggregate, binding material and water. Rapid increase The aggregate size is lesser than mm is considered as in construction activities leads to acute shortage of fine aggregate. The physical property of Iron Ore mining of natural sand, iron ore tailings which is the waste Tailings ...

The Influences of Iron Ore Tailings as Fine Aggregate on ...

· The present study looks for the feasibility of preparing UHPC with iron ore tailings (IOT for short) as fine aggregate. To enhance outstanding high performances, some influences on UHPC mortars were investigated such as different kinds of sands, different mix ratio of sands, and different largest particle size of fine aggregate. The results show that IOT have negligible poorer aggregate ...

iron ore waste as coarse aggregate in concrete

· Iron Ore Waste As Coarse Aggregate. Effect Of Partial Replacement Of Coarse. the solid waste from construction again as a material in the concrete to decrease the land fill of solid waste and decrease the scarcity of natural aggregates like gravel and sandOn the Other hand the GGBS is a byproduct in the manufacture of iron and the amounts of iron and slag obtained are of the same .

EFFECT OF PARTIAL REPLACEMENT OF COARSE AGGREGATE BY WASTE .

Iron ore, coke and limestone are fed into the furnace and the resulting molten slag floats above the molten iron at a temperature of ... to 1600° this experimental study, different mixes are cast, waste crushed tiles are used to partially replace the coarse aggregate by 10%, 20% and 30% and GGBS is used to partially replace the cement by 20%,30% and 40%. A total of 9 types of mixes of ...

Latest Posts

- السيليكا المعدنية

- Ibag مخروط محطم

- بناء مصنع سحق للبيع

- نيوزيلندا الاغتصاب سحق المعدات

- الاسمنت لصق

- الهند دلهي مطحنة الفحم الصانع

- شكل تقرير مشروع الحجر الطبيعي

- مطحنة الذرة الكندية للبيع

- أنواع الصخور في إكوادور

- التوربينات شفرة طاحونة السطح

- ضغطي خصائص الحجر

- sbm-7ft معيار مخروط محطم

- spargo الأسطوانة محطم الرماد

- بيع الرمال معدات التعدين

- مواصفات كسارات المحمولة القديمة

- Marble Crusher Factories In Karachi

- I Want To Buy Cheepest Grinder

- Industrial Training Report For Ee In Thermal Power Plant Free Download

- Grinding Wheel To Grind Ceramic

- 1963 Blake Jaw Crusher

- Price Stone Crusher In Nigeria Customer Case

- Suppliers Of Barytes In Nigeria

- Buy Copper Ore Processing Plant In Comoros

- All About Gyratory Crusher

- Iron Ore Grinding Plants

- Zenith Stone Crushers Lithuania

- Reconditioned Crankshaft Grinding Machine

- Flow Diagram To Show All The Mining For Coal

- Iron Ore Mining Equipment Sale Nigeria

- Mitigations To Improve Ore Production In Mining