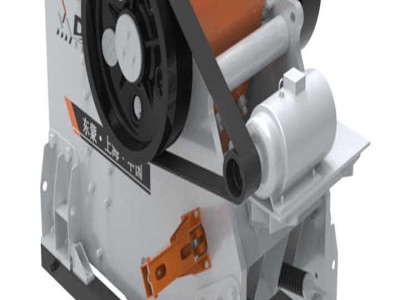

Size Reduction Equippment Using Roll Crusher

Keys to Quality Potash Production | TerraSource Global

The impactor is a highly versatile machine that provides high reduction ratios of up to 35:1. It also has superior topsize control allowing for maximum yield. Gundlach Crushers NanosizR® Roll Mill: Ideal for dry near size and oversize materials. This crusher has especially high tonnage crushing capacity – up to 40 tons per hour.

High pressure grinding rolls (HPGR)

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high pressure that it grinds the feed material to the desired smaller grain size.

Rock Crushing Rule of Thumb

Dec 16, 2015 · Cone crusher and short head cone: feed diameter < 25 cm; reduction ratio 5:1 to 10:1 usually 7:1; capacity 5 to 300 kg/s: Mohs hardness < 8. Usually secondary or tertiary crusher. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to 10:1; capacity to 50 kg/s.

How it Works: Crushers, Grinding Mills and Pulverizers ...

Jun 02, 2017 · During the primary crushing operation, boulder size feeds from 20 to 100 in. are reduced to secondary crusher sizes of 1 to 20 in. or mill feed size of .5 to 3 in. Many different types of crushers exist with varying designs and crusher processes.

Crushers, Pulverizers Mills

Crushers, Pulverizers Mills. Particlesize reduction, or comminution, is often required to prepare bulk material samples for testing. Crushing is often the initial step with materials such as mineral ores or aggregates using varying combinations of force, impact, and .

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

Laval Lab, the onestop specialist in Milling. For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical ...

size reduction

Mar 13, 2015 · Stickiness: A sticky material will tend to clog the grinding equipment and it should therefore be ground in a plant that can be cleaned easily. Soapiness: In general, this is a measure of the coefficient of friction of the surface of the material. ... Size Reduction EQUIPMENTS jaw crusher 29. Roll crushers 30. Hammer mill 31. Ball Mill 32 ...

Roller Mill/Flaking Mill Rolls

Roller Mill/Flaking Mill Rolls Roskamp Champion is the industryleading supplier of flaking and particle size reduction equipment. Our roller mill rolls and flaking mill rolls are manufactured to extreme precision using the highestquality base metals, ensuring the best fit for your equipment and your appliion, as well as long wear life.

Double Roll Crusher

Roll crushers have a theoretical maximum reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch. Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm).

Double Roll Crusher, 13mm Particle Size

Roll Crushers work well in preparing samples for further fine reduction using a pulverizer. Output size is controlled by adjusting the gap between the rollers using a hand lever. Feed hoppers offer high capacity, open easily for cleaning and maintenance access, and feature an electrical safety interlock that shuts down power to the unit when ...

Crushing Technology : Material Size Reduction Methods

Material trapped between a solid plate and a rotating roll is shorn by its contact with the teeth on the roll. Often the sheer crushing is combined with other crushing methods, such as compression, attrition, and impact, for mineral size reduction. For example, single roll crushers employ shear together with impact and compression.

Choosing the Right Rock Crushing Equipment

Jul 26, 2017 · Roll crushers are a compressiontype reduction crusher with two drums rotating about a shaft. The gap between the drums is adjustable. The particles are drawn into the crushing chamber by the rotating motions of the rolls and a friction angle is formed between the particles and the rolls.

Dryer Crushers for Simultaneous Grinding Drying ...

Using a Williams roller mill or impact dryer mill eliminates the need for separate equipment for size reduction, drying, and classifying. This reduces your initial equipment investment and leads to ongoing savings with the continuous, automated operations. Machines Capable of Grinding Drying

CPE: Lesson 16. Size Reduction Equipments

Size Reduction Equipments. There is a very wide range of size reduction equipment available and the following passages describe briefly the essential details of only a few of the most important types. (a) Hammer Mill: A standard hammer mill is shown in (Fig. ) and consists of a series of hinged or fixed hammers attached to a shaft ...

Products and Equipment from TerraSource Global

Roll crushers are available with Gundlach's breakthrough 3D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry's best dimensional product control, fewer fines and elimination of oversize material. Gundlach's roll crushers ...

Used Lump Breaker | Used Lump Crusher Delumper Machine ...

12 24 48 100 All. Layout. Used Prater Industries Flake Cake Breaker Lump breaker Crusher FB13X15 18313. S/N . Welded and bolted construction using mild steel. 13" X 15" product inlet with connecting flanges. Breaker height between flanges: 10". .

Size Reduction

Using multiple cylindrical rollers, we can reduce material down to 470 mesh with exceptional precision and consistency. Our Roller Mills operate without degrading the material. Equipped with a spring release roll to protect against foreign materials such as rocks, nuts, bolts, tools that may pass through the mill.

Service Improvements for Coal Crushers | Coal Age

Jan 26, 2012 · That should make for lively internal dialogue for the KTron Size Reduction Group, a subsidiary of Hillenbrand Inc., which acquired Pennsylvania Crusher and Gundlach. Gundlach builds some fairly large roll crushers. Pennsylvania Crusher .

Double Roll Crushers | McLanahan

Double Roll Crushers. Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds.

Particle Size Reduction Equipment Size Reduction Machine ...

Industry Leading Technology . MPE is the leading manufacturer of size reduction machines because of our countless innovations and features. Many aspects of our GranULizers are chosen based on the intended grind appliion—including roll corrugations, speed ratios, hermetically sealed design, and .

Grinding Mills and Pulverizers Specifiions | Engineering360

Size reduction equipment moist materials, slurries or dispersions. Search Logic: ... Roll Crusher Mills for intermediate grinding where feed is crushed between the nip of two rolls or between a single roll and a fixed surface. The rolls can be serrated, toothed or smooth. Rolls crushers tend to produce weaker shaped product particles compared ...

Latest Posts

- محرك مزدوج الأسطوانة محطم

- الأبحاث المتعلقة ب السيراميك الكرة آلة طحن

- بيع نظام النقل الكلي

- ضريبة القيمة المضافة محطم

- الأبحاث المتعلقة ب السيراميك الكرة مطحنة الكرة

- جنوب أفريقيا الصلب

- الفك السفلي مصنع تجريبي

- شنغهاي الفحم محطم نموذج

- خبث محطم صانع الهند

- مقدمة موجزة من الحجر الجيري والرمل والحجر ساحة

- تستخدم مطحنة رمل الهند

- المطرقة محطم طبل

- مطرقة مطحنة الورق المقوى للبيع

- تحديد أهم مصانع الاسمنت في الأردن

- Metal Crusher Seller

- Indiaportable Pyrite Mobile Crusher

- Jaw Crusher Type

- Mobile Jaw Crusher Mobile Rock Crusher Mobile Stone Crusher

- Sag Milling Installations

- Nakamura Stone Crushers

- How To Crush Bau Ite

- Belt Conveyor Cost Per Meter Of Installation

- 5 Ton Per Hour Rock Crusher Used

- Lignite Coal Particle Size From Mine

- Gambar Skema Belt Conveyor

- Crushed Limestone Sizing Chart

- Scholarshipships For Mining Students

- Commercial Grinding Mill Gold Processing Equipment Best Known

- Jsw Saw Bhilwara New Plant

- Bear Run Coal Mine Indiana In Puerto Rico