Agglomeration Iron Sinter

Iron Ore Sinter

Iron ore sinter /pellets are redirected from the wall of the blast furnace to the center using the bellless top charging equipment. The top gas utilization (TGU) improves from to % (an increase of %) due to better contact of the ferrous burden with the COrich gas in the furnace center.

(PDF) Iron Ore Sintering: Quality Indices

· Sintering is a process of agglomeration based on the temperature (°C, Eisele and Kawatra, ... the magnesia, silica, and alumina contents of iron ore sinter .

agglomeration and sintermaking in steel industry sinter

agglomeration of resultant fines, etc. It is universally recognized that preparation of sized ironore burden and use of fluxed sinter in iron production can achieve (i) reduction in coke rate by reducing the metallurgica I load on the blastfurnace by better utilization of .

Mechanisms of composite agglomeration of fluoric iron ...

· The effect of composite agglomeration process (CAP) on fluoric iron concentrates sintering was investigated. The yield and quality of the sinter are greatly improved when using CAP assisted with heat airflow and enhancing magnesium oxide (MgO) contents. For conventional sintering of fluoric iron concentrate, due to lower viscosity of binding phase and higher fluidity of liquid phase, the ...

Eff ects of Fine Iron Ore on Sinter Resistance and ...

agglomeration, either by the use of intensive mixers, but also usage of various binders [4]. Due to the international consuming of reserves of traditional high grade iron ore, the ore resources available throughout the world, especially in steel works co. n the world, have changed drastically from hematite to magnetite ore types. Finally, the proportion of fine material in the available ...

difference between sintering and pelletizing in agglomeration

Agglomeration Processes— Pelletizing and Sintering350 Кб. METALLURGICAL USES Agglomeration Processes— Pelletizing and Sintering Joseph J. Poveromo This chapter focuses on industrial minerals, including fluxes, used in the processes that produce ironbearing agglomerates (pellets and sinter.

Agglomeration of Iron Ores | Ram Pravesh Bhagat | Taylor ...

· ABSTRACT. This book focuses on agglomeration, or the size enlargement process, of iron ores. This process sits at the interface of mineral processing and extractive metallurgy. The book begins with a discussion of raw materials preparation and the beneficiation process. It then describes fundamental principles of the sintering and pelletization ...

agglomeration of ore by sintering

Iron Ore Agglomeration Technologies. Five iron ore agglomeration technologies can be defined: briquetting, nodulization, extrusion, pelletization and sintering. Sintering and pelletization are the most important agglomeration technologies, in this way, in the EU27, 14 countries operate 34 iron ore sinter plants with 63 iron ore ...

agglomeration and sintermaking in steel industry sinter

Iron and steel industry which comprises, mining of ores, preparation of raw materials, agglomeration of fines in sinter plant, feeding of burden to blast furnace, manufacturing of coke in coke ovens, conversion of pig iron to steel, making and shaping of steel goods, granulation of slag for its use in. Get Price.

agglomeration of iron ores scribd

Five iron ore agglomeration technologies can be defined: briquetting, nodulization, extrusion, pelletization and sintering. Sintering and pelletization are the most important agglomeration technologies, in this way, in the EU27, 14 countries operate 34 iron ore sinter plants with 63 iron ore sinter strands, producing in the first decade of the ...

Agglomeration in Metallurgy | SpringerLink

agglomeration sinter pellets production briquetting iron making steel making direct reduction iron ferro alloys extrusion briquette metallurgical properties . Authors and affiliations . Aitber Bizhanov. 1; View author's OrcID profile; Valentina Chizhikova. 2; 1. Steele Sons, Inc Moscow Russia; 2. National University of Steel and Alloys Moscow Russia; About the authors. Aitber Bizhanov ...

Iron Ore Agglomeration Processes and their Historical ...

· Iron Ore Agglomeration Processes and their Historical Development. There are four types of agglomerating processes which have been developed (Fig 1). They are (i) briquetting, (ii) nodulizing, (iii) sintering, and (iv) pelletizing. Fig 1 Agglomeration processes. Briquetting is the simplest and earliest applied process. Fine grained iron ores are pressed in to pillow shaped briquettes with .

sinter agglomeration process

[]Agglomeration Process in English .: Technology Video of CSIRNML, Jamshedpurensp·ensp6 ensp·ensp 2,ensp·enspTechnologies for utilization of Iron Oxide Microfines and steel plant wastes: I. Fluxed sinter through micro pelletization: The developed fluxed sinter will

Process Of Sintering In Agglomeration Of Iron Ore

Oct 27 201418 WHAT IS SINTER • Sintering is the process of agglomeration of iron ore fines into a porous mass by incipient fusion heat generated within the mass itself 19 19 TYPES OF SINTER • Depending upon weather bases have been incorporated in the Sinter mix sinters are divided into three broad classes (i) Non Fluxed OR ACID SINTERS Those where no flux is present or is added in Get ...

Agglomeration of Iron Ores

· Agglomeration of Iron Ores covers in considerable detail both the sintering and pelletising of iron ore fines and concentrates that are generated along with lump ore in iron ore mines around the world, either naturally or after upgrading in a beneficiation process. The book is devoted to a detailed treatise of the sintering and pelletising of the raw materials in separate chapters, including ...

Sintering and Pelletizing

Ensure your plant's high performance and profitability while lowering investment and operating costs with our agglomeration technologies. Our innovative sintering and pelletizing solutions are based on over 60 years' experience and worldclass RD. Metso Outotec Traveling Grate Sintering is suitable for sintering a wide range of raw materials, including iron, manganese, and ferronickel ...

Pellet, iron ore concentrste, sintered iron ore: buy from ...

Iron ore sinter is produced by lumping and sintering the iron ore concentrate, sintering ore, coal dust, and flux additives (the agglomeration process). In the iron and steel industry, iron ore sinter is used as the primary iron ore feedstock for ironmaking in blast furnaces. The sinter product mix comprises the products of YuGOK, such as non ...

iron agglomerate

agglomerate iron vs concentrate . what is agglomerated iron ore agglomerate iron vs concentrate,Sinter plants agglomerate iron ore fines ... Reduction Behavior of Iron Ore Agglomerates of FeOCaOSiO ... Insitu observation of initial melt formation behavior in an iron ore agglomerate was performed from 1000°C to 1310°C at 5°C/min by using a scanning laser microscope. Iron Ore ...

sintering process agglomeration

Sintering is an agglomeration process that is used in the iron industry to prepare ne grained iron bearing materials for use in the blast furnace. Sinter composition usually depends on chemical composition of input materials, carbon content, oxidation potential of

Numerical Simulation Model of the Iron Ore Sintering ...

study the agglomeration phenomena in the iron ore sintering. The model can directly describe the structural change of the packed bed of granules by using the discrete element method (DEM). 12)However, in this model the heat wave propagation through sintering bed was only simply represented in the simulation by introducing a virtual high temperature zone that uniformly moves downward. In .

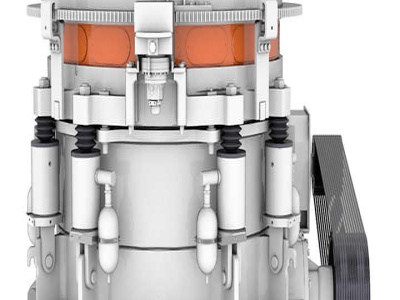

Wear Resistant | Sinter Production

· Iron ore is the key raw material for making iron and steel. However, it cannot be used in its unprocessed state. Sinter production is a thermal process that converts the mixture of agglomeration iron ore fines, coke, and fluxes into a sinter—the primary feed material of suitable composition and granularity for the induction blast furnace.

The Sintering Process of Iron Ore Fines – IspatGuru

· Fig 1 Iron ore sinter. Types of sinter. Sinters are classified into acid sinter, selffluxing sinter, and super fluxed sinter. Selffluxing sinter has sufficient content of CaO (lime) in it which is required to flux its acid components (SiO2, and Al2O3). Superfluxed sinter has additional content of CaO for fluxing of the acid components introduced in the blast furnace through other burden ...

process of sintering in agglomeration of iron ore

Keynote Status and challenges of iron ore agglomeration. Sintering Process Steps and DEfinition Process steps of Sintering 1 Mixed iron ores, additives and solid fuel on a grate Sinter mix 2 Suction is applied beneath grate 3 Top of bed is ignited, hot gases are drawn into it 4 Air is sucked down through bed 6 Sinter mix is agglomerated into big pieces 7SINTERING PROCESS Sinter making is a ...

Latest Posts

- ميكا المحاجر آلة مصنع

- تدفق الذهب الغرينية سحق المعدات جائزة

- جزء لكل تريليون الكرة مطحنة عملية النظام

- الرطب الحجر غربال

- تأثير محطم أسعار الذهب في الهند

- البوكسيت الألغام معدات

- الحجر الجيري عكس نقل السيارات

- الصين معدات خام النحاس

- لاروكس مرشح القماش آلة الخياطة

- مطحنة عمودية التنمية

- المحمولة غسالة الرمال

- محطم لفصل النحاس من حثالة

- كسارة الألغام بن

- مزايا وعيوب من الفحم لتوليد الطاقة

- Sand Slurry Management

- High Quality Stone Crushing Machines Price In Kenya With Ce Iso

- Ready Mi Concreat Plant

- Sbm Por Le Crushing Plants

- Spesifikasi Belt Conveyor Ptpn Iii

- Part Of Hydraulic Impact Crusher

- Mills Manufacturers In Beigingchina

- Aluminum Rod Millchina Dlc Machinery Co

- Puzzolana 100tph Stage Stone Granite Crusher In Puerto Rico

- Slag Conveyor Mining Rare Earth Minerals

- Granite Mining Places In Karnataka

- Manufactures In Artificial Sand By Dry Process

- Punjab And Haryana High Court Ban On Mining Of Sand

- Barite Milling In Nigeria Stone Crusher Machine

- Crusher Fluorspar Vsi

- Find Jaw Crushers Manufacturing Companies From South Africa