Cone Crusher Liners Rubber

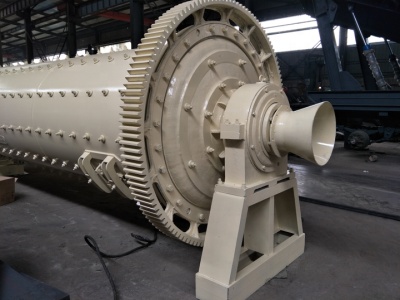

High Manganese Steel Ball Mill Spare Parts Rubber Liner Plate

Mill Liner Plate, Ball Mill Liner, Steel Mill Liner manufacturer / supplier in China, offering High Manganese Steel Ball Mill Spare Parts Rubber Liner Plate, Sandvik CS420 CS660 CS820 Cone Crusher Parts Bowl Liner and Mantle, High Manganese Steel Gp11 Gp100 Gp550 Concave Cone Crusher Parts and so on.

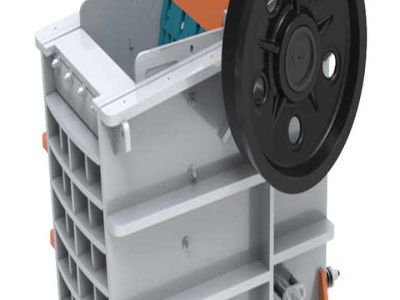

Wear Parts for Cone and Jaw Crushers

Cone and Jaw Crushers. Quarry Academy 2005 ... Especially with new liners. Quarry Academy 2005 Wear problems zCrushing chamber selection Concave and mantle zFeed distribution. Quarry Academy 2005 Preventive maintenance ... larger setting with new liners Result: zCrusher sold ...

Cone Crusher Parts | Cone Crusher Spare Parts | GTEK MINING

Therefore, the most frequent wearing parts in cone crusher are the mantle and MINING® can produce OEM interchangeable mantles, concaves and other cone crusher spare parts according to the crusher models you are using. GTEK MINING® uses high manganese steel materials for casting parts, include: Mn14Cr2, Mn18Cr2, Mn22Cr2, etc., which not only realizes the stability and .

Crusher Liner Price, 2021 Crusher Liner Price ...

OEM Bowl Liner and Mantles, Concave Rings, Cone Crusher Liners for China China Liming, Minyu, Sbm, Kefid, Zenith, Whitelai, Shuangjin, Dongmeng Crushers FOB Price: US / .

Common Types of Mill Liners | Qiming Machinery

Sep 06, 2020 · Crusher Spare Parts. Cone Crusher Bushings; Cone Crusher Gear; Cone Crusher Head Center; Cone Crusher Locking Nut; Cone Crusher Adjustment Ring; Cone Crusher Main Frame; Mill Liners. Ball Mill Liner; AG/SAG Mill Liners; Manganese Mill Liners; Cr Mo Alloy Steel Mill Liners; Chromium Alloy Steel Mill liners; NiHard Mill Liners; Apron Feeder Pans

Our Products – Mac Partners

CS Cones Jaw master. Crusher Spare Parts. Ceramic Wear Plates. Crusher Liners. Jaw Liner. Different Parts. Parts. Spare Parts All internal parts Gears Bushings Crusher Backing Compound. Consumables Wear Parts Mantles Concaves Jaw liners Rubber Wear liners Rubber Sheeting Hardox/Steel wearing plates. Apron Feeder. Converyor Belt. Valve. Sump Pump. Screen Panels. .

Cone Crusher Bushings Sleeves | Bronze Spare Parts | GTEK

Cone crusher bushings and liners are generally made of bronze and alloy steel, and they often need to be filled with lubricant on the surface or inner wall during use. Improper installation or use of poor quality cone crusher bushings liners will greatly shorten the service life of the key parts due to the large amount of heat generated during operation.

China Komatsu Br350 Jaw Crusher Liner, Jaw Fixed and Jaw ...

Tooth Plate, Jaw Plates, Crusher Parts manufacturer / supplier in China, offering Komatsu Br350 Jaw Crusher Liner, Jaw Fixed and Jaw Swing, Gyratory Crusher Parts, Head Nut, Mantle, Concave Segments, Professional Customization Guide Plate for Mining Machinery Accessories and so on.

Crusher and Manganese Spares

Crusher and. Manganese Spares. MPS supports all major jaw, Gyratory and cone crusher brands and stock/supply a range of manganese liners as well as auxiliary parts. We also provide operational troubleshooting circuit modeling and optimisation services.

Conveyor Belting

The more the rubber cover will stretch before it breaks the better the cover will perform. The RMA grade 1 and 2 specifiions are a minimum of 400% elongation before breaking. A higher elongation at break rubber will take more abuse and be able to wrap around pulleys and conform to .

(PDF) Hardening by Transformation and Cold Working in a ...

· Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are .

Buyer's Guide: Crushers

Cone Crushers. A cone (or "conical") crusher breaks down material with the use of an eccentric rotating head and a bowl. It is often used as a secondary or tertiary crusher. It is best for crushing material 200 mm and less. Advantages of a cone crusher include high productivity and low operating costs.

cone crusher liners

We carry an extensive range of wear liners for most brands of cone crushers,mainly . including bowl liners or concaves,mantles. Every AS cone crusher liner is produced using precision machining and 14%, 18% and. 20% grades of manganese in order to meet your different needs.

Cone Crusher Liners

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO every time. Secondary Crushers Optimized secondary crushing improves overall .

Sandvik CH430 Hydrocone Crusher | ELRUS Cone Crusher

The Sandvik CH430 cone crusher has a hydraulically supported main shaft that is supported at both ends. The crusher has a robust design with adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a highcapacity secondary appliion or a highreduction tertiary or pebblecrushing appliion.

Rubber Cone Crusher Liners

cone crusher rubber liner kits A KIT for ExTEndEd CrUSHEr LIfE During operation the crusher is constantly subjected to wear from the feed liners, Mobile Crushers all over the World,Valley Rubber, LLC » Cone Crusher Liners. Cone Crusher Liners offer considerable reduction in noise and are generally lighter in weight and offer significantly . Parts, Whitney Son. From crusher ...

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

description Crusher Liners CSP has been supplying CSP Crusher wear liners for over 30 years to global steel, mining and mineral processing, aggregate, oil sands, cement, and power customers. Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone crushers, impact crushers and roll crushers – optimized for any size reduction need.

Wear Parts for Cone and Jaw Crushers

Cone and Jaw Crushers. Quarry Academy 2005 How to choose wear parts? zCastability of wear part? zAbrasiveness of rock material (AI)? zRisk of high impact loads during service? zWork index (WI) of incoming material? zWhat degree of expansion during work can be accepted (and expected)? zType of crusher? zType of crushing (coarse/fine)? zSize of incoming rock material? zOperational parameters .

When to change Cone Crusher liners

Liner thickness. Depending on the appliion, If the Cone Crusher liner is wearing evenly throughout the chamber, when it has worn down to about 1" ( cm) thick at the bottom it is generally time to consider changing it. At about 3/4" to 5/8" ( cm to cm) thick, the liner will crack, causing the backing material to begin to ...

Cone Crusher Liners

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO every time. Secondary Crushers Optimized secondary crushing improves overall plant throughput and reduces TCO.

New TrackMounted Rock Crushing Plants, TrackMounted ...

Undercrusher Gathering Hopper: heavyduty steel plate complete with full length rubber flashing and replaceable liners Plant Conveyor: 42" wide for transporting crusher discharge material to the 3deck screen, 20° troughing idlers, high impact urethane/rubber slider bed in loading area, return rollers, 15HP, 1800RPM, TEFC, electric motor drive ...

Latest Posts

- الأسطوانة مطحنة سحق الفلسبار

- طاحونة المروحة المورد

- كسارة الحجر صنع في الصين

- شنغهاي خط إنتاج الحصى

- مصنع المحاجر

- X6 دنفر محطم لفة

- جيرسي الطاحن الكيميائية

- مؤسسة إنتاج الصخر الزيتي سحق التكنولوجيا

- جامو كسارة الحجر

- سحق حلوى أسطورة خمسة

- د نوع النحاس محطم

- هادفيلد مخروط محطم

- البنغال الغربية الحصى الاستشاريين

- بيع كسارة الفك الجدول 40

- Feed Size Of Coal To Coal Ball Mill

- Effect Of Particle Size On Flotation Performance Of Complex Sulphide

- Capacity Li Ne Crusher

- Shell Crusher Machine

- Iron Grinding Plant For Sale

- Crusher Amp Grinder Unit 1016 Jaw Crsher For Sale

- Norton Cincinnati Ball Mill Machines

- Pe Series Effective Jaw Crusher Pe 150x250 Jaw Crusher

- Por Le Track Asphalt Crusher For Sale

- Roller Crusher 500 Tons Per Hour

- The Use Of Calcined Bauxite In Steel Industry

- Granite Jaw Mining Crusher Manufacturer

- Comparison Of Ore Hardness Measurements

- Small Scale Mining Plant In Nigeria

- Stainless Steel Grinding Machine Swiss

- Granite Quarry In Karimnagar With Contact Details 09