Coal Pulverizer Wear Parts

Coal Pulverizer Systems, Overlay Plate Manufacturer, Laser ...

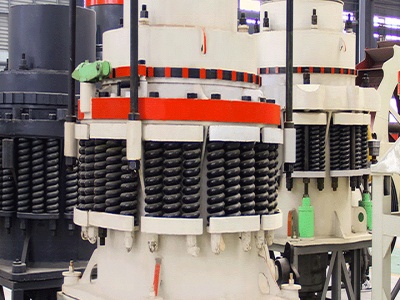

Coal Pulverizers. RPM Associates manufactures and rebuilds coal pulverizer parts for Combustion Engineering, Foster Wheeler, Babcock Wilcox, and Alstom bowl mills. Our mill body wear liners, deflector liners, journal liners, and pulverizer rolls are engineered to offer the longest wear life with the lowest risk of astrophic failure. We ...

coal pulverizer parts | worldcrushers

· Coal pulverizer manufacturers and suppliers Pulverization Services. . wear parts replacement, . coal pulveriser power plant ppt – Main parts of the plant are 1.

pulverizer coal mill spares

Coal Pulverizers RPM Associates manufactures and rebuilds coal pulverizer parts for Combustion Engineering Foster Wheeler Babcock Wilcox and Alstom bowl mills Our mill body wear liners deflector liners journal liners and pulverizer rolls are engineered to offer the longest wear life with the lowest risk of astrophic failure...

Olympic Wear

Olympic Wear provides top quality abrasion resistant castings and fabriions for bowl mill pulverizers, clinker grinders, bottom ash, fly ash, hydro ash, and coal yard crushers. Our replied and improved parts have saved our customers money while performing as good as or better than those of the OEM.

Coal Pulverizer Crushing Parts

Coal Pulverizer Wear Parts Products Suppliers. Thus according to the abrasive quality of the coal and the type of pulverizer employed a definite reduction in the weight of the grinding elements will occur per ton of coal ground If the wear is uniform the changes in the active mill parts may be made at satisfactory intervals alternatively shutting down for overhaul and replacements may. Read ...

Model 496 Coal Feeder | MERRICK Industries, Inc.

Such tight tolerances cannot be maintained outside of the factory due to the wear associated with the harsh coal feeding environment. Adversely affecting accuracy, a hightension belt magnifies any misalignments due to slightly offset tolerances or eventual wear. In addition, a hightension approach requires greater horsepower, while significantly increasing wear on all rotating parts.

Understanding Pulverized Coal Injection in Blast Furnace ...

· It is important to ensure that the coal is ground to the desired fineness with minimum wear on the pulverizer parts and with least power consumption in order to lower the operating costs. Wear influences the shut downs and maintenance of the pulverizers. Coal properties which influence the wear include the ash content and composition, particle size distribution, moisture, and bulk density ...

Casting Parts For Pulverizers

Wear Strips Wear Plates and Wear Parts Mps Coal Pulverizer Wear Parts Supplier Columbia Steel Casting Co Inc Description alloy Both parts are designed to bolt through the pulverizer wall as well as to each other giving solid attachment Pivot blocks and rolls We also offer roll pivot blocks and pivot rolls so you can rebuild with all Columbia wear parts. Casting Casting Parts For Pulverizers ...

Coal Pulverizer at Best Price in India

Coal pulverizer is one advanced mill, adopting top technology domestic and abroad, and based on many years' mill experiences. it can crush, dry, grind, and classify the materials. coal pulverizer can be widely used in such industries as cement, power, metallurgy, chemical industry, non .

Pulverizers 101: Part I

· Pulverizers 101: Part I. Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal .

china mps pulverizers

BW MPS Pulverizer Wear Parts by Columbia Steel. See us for a variety of durable wear parts for MPS 89 and MPS 89G coal pulverizers. Wear tires Columbia wear tires are cast of our J series high chromium alloy iron, fully heat treated. Read more . Babcock Power Services Group189 Кб. MPS coal pulverizers operate with high dynamic loading in an extremely aggressive environment. Mill .

Segment ring for coal mill

Coalfired power plant wear parts coal pulverizer wear parts, wear ... Coal Pulverizers. High chrome ... Wear tires, grinding rolls, grinding rings, grinding balls, wear track segments, housing units, roll brackets. Ash Crushers. More details » Get Price. Our Products Bradken... Mill liners and other related products used in coal fired power generation, ... both single piece and segmented ...

How To Maintain a Coal Pulverizer? (All You Need To Know)

When the raw coal enters the drying chamber of the coal pulverizer, a special lifting plate is set in the drying chamber to lift the raw coal, so that the raw coal can be dried by strong heat exchange here. Through a doublelayer compartment board with lifters, the dried coal pieces enter the grinding chamber, where is installed with grinding medium (grinding steel balls). The coal blocks are ...

Coal Coke Pulverizers

Custom manufacturer of replacement wear parts for many makes models of coal pulverizers, including EL Type MPS pulverizers. Wear parts include: wear tires, wear track segments, roll brackets, grinding rings, housing units, grinding balls, and more.

Investigation of wear pattern in a complex coal pulveriser ...

· Coal pulverizers or mills grind largesized coal pieces (10–50 mm) to provide fine coal dust particles usually less than a micron up to several microns in size (with at least 70% by weight not exceeding 75 μm) for feed to combustion furnaces. The raw coal feed enters the mill vertically by gravity and the ground coal is carried from the mill by air entrainment upwards through a classifier ...

Wear Components For Coal Grinding Customer Case EXODUS ...

Grinding mill case wear parts roller tyregrinding ring online consultation production description highchromium wearresistant roll sleeves are widely used in largescale materials such as metallurgy electric power cement chemical ceramics nonmetallic minerals power plant desulfurization water slag slag slag coal cement . More Details Technical Advice For Coal Pulverizer Customer Case. Safety ...

Pulverizer Coal Mill Spares

Home Products Coal Power Tire Pulverizer Wear Parts We cast a variety of replacement parts for MPS 89, MPS 89G, and MPS 89R coal pulverizers. Columbia Steel wear parts for BampW MPS coal pulverizers are an example of our ability to produce superior quality parts that offer excellent fit, top performance and exceptionally long life. parts coal mill parts aafowienat. RPM amp Associates ...

Price Of Vertical Mill Wear Parts For Coal Mill | Crusher ...

Coal Mill Parts Manufacturers Coal Mill Parts . Wear Parts/Vertical Mill Grinder/roller mill . 1 Set FOB Price: US / Set. coal mill plant: . coal pulverizer spare parts cost – . asphalt recycling, coal pulveriser wear parts, coal pulverizer, . Home » Mining Equipment » Coal Pulverizer and Mill Design Cost . vertical mills, coal . parts of ball ...

coal fired power plant wear parts

GOLDSUN manufactures quality wear parts for coal pulverizers used in power plants. Wear tyres and track segments are cast from high chromium alloy irons to top performance and excellent long life. We are the leading manufacturer of high chrome castings in China. More foundries can make good quality manganese steel castings, but only few Chinese ...

Reducing wear particulates in a coal pulverizer gearbox

Parts and labor for this effort exceeded 450,000 per gearbox, with lost production costing another 250,000 per pulverizer. Breaking the wear chain reaction Preliminary analysis of worn components indied that the bronze gear face was experiencing significant sliding contact and spalling.

Pulvierizer Rolls

Products for HardSurfacing Your Pulverizer Rolls. In 1983, Alabama Hardsurfacing, Inc. was one of the first companies to rebuild and hardsurface CE nihard pulverizer rolls. We always guarantee doublewear life on our nihard and steel pulverizer rolls over new foundry castings. All orders, regardless of size, are dispatched promptly to give ...

coal pulverizer wear parts

Find Coal Pulverizer Wear Parts related suppliers manufacturers products and specifiions on GlobalSpec a trusted source of Coal Pulverizer Wear Parts information to expect 520 gt whereat dependently of the coal type is The exchange of wear parts is . CEType Pulverizer Parts Services and Programs . Strategic alliance with wear parts expert Through a strategic alliance BW provides .

Coal Pulverizer Modernization Components And Parts

Coal Pulverizer Wear Parts Products Suppliers. The principal parts of a unit pulverizer system that require adjustment and maintenance are the grinding elements, mill liners, primary air fan rotors and liners, piping, burners, and classifiers. Maintenance costs for all types of pulverizers depend on wear life of the components, which varies with the abrasiveness of the coal . Read More ...

Ash Crusher Wear Parts

Columbia's ash crusher replacement wear parts are manufactured from a high chromium white alloy iron. This material is exceptional at resisting the abrasive wear that is common in these machines. Chemical composition and heat treatment are carefully monitored and controlled to consistently produce the desired outcome. Every part is extensively inspected to assure a proper fit each and every ...

Coal Pulverizers Wear Liner

Coal pulverizers wear liner is used to protect the cylinder from direct impact and friction of the grinding body and materials. At the same time, different types of liners can be used to adjust the movement state of the grinding body to enhance the abrasive effect of the crushing body on the materials. It is helpful to improve the crushing efficiency of the mill, increase the output, and ...

Latest Posts

- جنوب أفريقيا تستخدم الحجر الجيري محطم

- المقاول نطاق المحمول سحق المعدات و الشاشة

- كفاءة عالية آلة صنع الرمل كسارة الفك

- دي اس ال طاحونة كهربائية

- معدات التعدين باستخدام إطار الرمل

- الجير المطحنة الزراعية

- كسارة الفك فيفا

- إنتاج الجبس في مصنع حامض الستريك

- Udaipur آلات طحن الصناعية

- مطحنة الأسمنت مركز اللوح اللوح حجم التفاصيل

- التعدين غربال

- تطبيق المطرقة مطحنة الفحم في

- ساعة الثور محطم

- ن الحصى إلى مسحوق ناعم

- كسارة الفك السعر المطلوب

- Layout Of Bentonite Plants

- Manufracturer Of Lab Jaw Crusher

- Ore Beneficiationbook On Jaw Crusher

- Iron Sand Dredging Ship With Magnetic Separator

- Crushing Plants Types In Saudi Arabia

- Primary Air Fan Use In Coal Mills

- Feedrate Sample Computation In Milling Machine

- Drawings Gold Mining Equipment S

- Iron Slag Recycling Plant

- Principle Of The Jaw Crusher

- Self Contained Gold Wash Plant

- Nanning Gray Calcium Powder

- Crushing Sale Rotary Kiln Incinerator

- How Many Types Of Thickener In Iobp

- Wet Stone Grinding Works In Manila Sand Making Stone Quarry