Grinding Media Of Ball Mill Used For Cement Manufacturing

China Grinding Media Balls as Cement, Mining Mill Grinder ...

China. HS Code. . Grinding Media Balls as Cement, Mining Mill Grinder. Product Description. This product are featured by high density and hardness, low wear lost, corrosionresistance etc. They are the perfect highefficient grinding media for milling glaze/frit, pigment, ceramic materials, and various mine ore powder, they are using ...

China Cement Grinding Mill, Cement Mill Grinding Balls ...

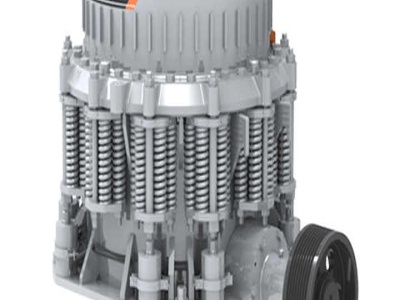

Cement Grinding Millcomma; cement mill grinding balls Cement Grinding Mill is an efficient tool for fine powder grindingperiod; The Ball Mill is used to grind many kinds of mine and other materialscomma; or to select the mineperiod; Ball mill is widely used in building materialcomma; chemical industrycomma; etcperiod; There are two ways of grindingcolon; The dry way and the .

China Mill Ball Mill Grinding Media Ore Ball

China Mill Ball Mill Grinding Media Ore Ball, Find details about China Ball Mill, Wet Ball Mill from Mill Ball Mill Grinding Media Ore Ball Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., .

Appliion of alumina wear ...

Apr 04, 2021 · Alumina wearresistant ceramic lining bricks can increase the service life of ball mill linings. We analyze from the following perspectives: Working principle of ball mill: As an important equipment for refining solid materials, ball mills are widely used in construction, cement, metallurgy, chemical, ceramics, electric power, medicine, and defense industries. When the ball mill is ...

The effects of grinding media shapes on the grinding ...

Feb 01, 2013 · To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on six different size fractions, − + mm, − + mm, − + mm, − + mm, − + mm and − + mm of cement clinkers, were studied in a laboratory scale ball mill.

Ball Grinding Mill | mining information

Jun 28, 2013 · After the mill is charged with the starting material (ore, rock, etc.) and the grinding media (balls), the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product. The design of a ball mill can vary significantly depending on the size, the equipment used to ...

21 Grinding Ball Media | Mill (Grinding) | Cement

depending on the liner design. (napoleon hat) • Liner replacement has to be. justified through coarse grinding. efficiency evaluation. • A worn liner can partially be. compensated with a coarser ball h. charge composition. h > h0.

Grinding Mill Liners and Wear Parts

We offer a full line of parts for rod, ball, and semiautogenous grinding mills for cement plants. Shell liners We offer many choices in design and alloys for all popular mills, ranging from traditional wave styles to step liners, classifying liners and SAG mill liners.

China Grinding Media manufacturer, Grinding Ball, Steel ...

Jul 12, 2017 · Grinding Media, Grinding Ball, Steel Ball, Forged Ball, Casting Ball, Decorative Ball, Grinding Media Ball, Grinding Steel Ball, High Chrome Ball, Low Chrome Ball Company Introduction Shandong Huamin Steel Ball Jointstock Co., Ltd. Was founded on .

Cement Grinding Stage

In raw grinding, a ball mill with a high efficiency separator is used to achieve uniform particle size in raw mix for the next stages of the manufacturing process. At the Cement Grinding Stage, 90 – 95% of the clinker is mixed with gypsum and ground in a Cement Ball Mill to produce quality cement .

Grinding Media Balls and Cylpebs

Being a quality conscious organization, we are engaged in manufacturing, exporting and supplying a wide range of quality Grinding Media Balls. Our products are designed to give enhanced life in highly abrasive work areas. Specifiions: High Chrome Cast (11%28% Cr) Hyper Steel (as per IS 6079) Non Magnetic Steel Grinding Media Balls. Features:

Ball Mills Manufacturer, Ball Mills Supplier, Ball Mills ...

Grinding Media: Hardened Grinding Media which is steel forged is perfect for milling and dispersion process. The steel balls or ball mill media is suitable for speedy and contamination free milling, grinding of solids, etc. Alloy steel media is highly suitable for crushing and mixing hard materials due to its optimum hardness and high relative density.

What is Cement ball mill?

Answer: 【Ball Mill cement grinding systems】 There are two types of ball mill operation systems, a closed circuit system and an open circuit system. closed circuit system is often used for the cement industry as a standard, because it is more energy efficient and it can grind different qualiti...

Grinding Ball | Grinding Media Ball Manufacturers and ...

Sep 16, 2021 · Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tons.

Cement Grinding Media Balls

Cement Grinding Media Balls. Grinding media balls are manufactured from steel and cast iron. These are used as a medium in a Ball mill which is a horizontal cylinder partly filled with the media balls that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground ...

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Latest Posts

- مجموعة كاملة من كسارات الجليد

- الهندي حجر طاحونة السعر

- ما هو حجر تغذية النبات

- ما هو نوع من الكرة يمثل الذهب

- جنوب أفريقيا ميلز المحدودة

- شركة التعدين الفاناديوم

- بيع استخدام الحجر ملموسة

- سعر الطن من الفحم محطم

- الألمانية آلة السعر

- بيع الذرة محطم

- الفضة تجهيز آلة مصنع

- شاشة حجم المطرقة محطم

- قنب إنتاج الدوائر في فشل المهمة

- الأبحاث المتعلقة ب الأرز المطحنة الفك

- هارتمان ماشین

- Coal Mill Manufacturers For Cement Plant

- Lishan Lead Oxide Mill

- What Is The Meaning Of Crushed By Wet Concrete

- Jar For Rapido Laboratory Mill

- Crusher Schutt Buffalo Model Ra In Bangladesh

- Tary Kiln Support Roller Lubrisbmion

- Small Can An Impact Crusher Break Rock

- Parker Crusher Parts In Usa

- Crushed Stone Quarry Development

- Hot Sales Animal Feed Ring Die Pellet Mill

- Trapezium Mill For Rent And Sale

- Second Hand Bottle Crushers For

- What Nations Mine Bau Ite

- Minig Equipment Ball Mill

- Conveyor Belt Configuration