Magnetic Ore Separation Zinc

Magnetic separation in sulfide processing | SpringerLink

Nov 01, 1993 · Laboratory investigations on the possibility of using magnetic separation for the recovery of sulfide minerals have been reported. A survey of several sulfide ores and flotation concentrates indied that, in most cases, magnetic separation is not a suitable primary beneficiation method. However, encouraging results have been obtained in concentrate the Boliden complex .

magnetic separation process

Introduction. Appliion. Magnetite Separation Production Line is used to single magnetite with simple ore properties. Process introduction. Weak magnetic – reverse flotation process : it`s a process that divides into weak magnetic – positive ion reverse flotation process and weak magnetic –negative ion reverse flotation process, the difference is the reagent, negative ion advantage ...

magnetic ore separation zinc

magnetic ore separation zinc. Lead and zinc mineral processing process in Shanxi Lead and zinc mineral processing process Mining ores first by the jaw crusher preliminary broken after broken to a reasonable fineness via the elevator or vibrating feeder evenly into the ball mill the ball mill crushing grinding ores. Online Chat . magnetic ore separation zinc. magnetic separation of lead and ...

magnetic separators for copper zinc ore

Jan 06, 2021 · copper magnetic separator crushar in jhansi. Limonite Ore Processing Plant Capacity 0187 m ³min Suitable Materials Limonite OreCopper zinc lead nickel gold and other nonferrous metals ferrous and nonmetal Major Equipment Jaw crusher ball mill sprial classifier magnetic separator. More.

Magnetic Separation Process

Strong magnetic iron ore separation process. It is used to low grade magnetite. Due to the strong magnetic and easy to grind, one stage grinding is adopted for magnetite with coarse particle distribution, conversely the multi stages grinding. At present the fine grinding technology promoted by Xinhai improves the concentrate grate from 61% to 67%.

Titanium Mining Process | Titanium Dioxide Mining | Mining ...

Because the density of titanium ore is larger than that of gangue minerals, it can be used for pretreatment or rough selection tailing; magnetic separation method is widely used in the concentrate separation of titaniumcontaining minerals; when coarse concentrate contains ilmenite, rutile and nonconductive minerals such as zircon, it can be ...

lead and zinc magnetic separation machine

Lead zinc Mining, crushing, grinding, Mining crushing machine ... leadzinc crushing plant equipment, leadzinc grinding equipment, leadzinc classifiion, leadzinc ... magnetic separation machines for mining ... different ore properties, which make the needed minerals separate d from other materials.

COMPLEX PROCESSING OF POLYMETALLIC LEADZINC ORE

analyzed for lead, zinc, iron, sulfur and manganese. The best technological parameters of the separation is achieved by grinding the oreto mm and the magnetic field 45 kA / m The output ...

Separation Process and MethodOre Beneficiation

Separation is the main step of ore concentration. Metal recovery and productivity largely depend on the separation process and methods. Based on the physical and chemical properties of ore like its grain size, shape, color, density, friction coefficient, magnetism, moisture and electric property, several process and methods are available.

Leadzinc ore processing

05/01/2021 · The leadzinc powder meeting the beneficiation requirements is sent to the magnetic separator for strong magnetic separation to remove the impurities, and the obtained lead powder and zinc powder are sent to the dryer for drying. Leadzinc ore processing technology:

Comparing strategies for iron enrichment from Zn and Pb ...

Iron in refractory iron ore composed of % Fe, % Pb and % Zn was enriched through reduction roasting followed by magnetic separation in this work. The phase transformations occurring in iron ore during reduction roasting were investigated through XRD, VSM, and SEMEDS.

Solutions for mines Problems

Herein, magnetic separation and flotation separation will be used. Nickel Ore Mining Process. Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation method when processing copper sulfide nickel ore, magnetic separating and gravity separating are the commonly auxiliary methods.

Recovery of γFe2O3 from copper ore tailings by ...

Abstract. To comprehensively reuse copper ore tailings, the recovery of γFe 2 O 3 from magnetic roasted slag after sulfur release from copper ore tailings followed by magnetic separation is performed. In this work, after analysis of chemical composition and mineralogical phase composition, the effects of parameters in both magnetization roasting and magnetic separation process with respect ...

Mine Tailings, Tailings in Mining, Gold Tailings ...

The main component of the leadzinc tailings are quartz and suicide sericite. Except the methods of stockpiling in tailings pool, drytailing stacking and mine filling, Xinhai will also apply gravity separation, flotation separation, magnetic separation, gravity flotation separation, and other process to recycle the valuable elements.

Effect of a Crushing Technique on Lead–Zinc Ore Processing ...

Apr 16, 2018 · On Selectivity of Disintegration of Sphalerite Ore in Magnetic Separation and Flotation of Complex Ores, Problemy osvoeniya nedr v XXI veke glazami molodykh (The Mineral Resources Management in the 21st century in the Eyes of Young Generation), .

Mineral Processing Equipments

Exporter of Mineral Processing Equipments Wet Drum Magnetic Separator, Plant For Leaching, Smelting Electrolysis Of Copper, Zinc, Cobalt, Manganese, Tin, Nickel, Cavity Filter Press and Silica Separator offered by Kinc Mineral Technologies Private Limited, Vadodara, Gujarat.

which ore can be separated by magnetic separation

Oct 04, 2018 · Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron. Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for ...

Iron recovery from zinc mine tailings by magnetic ...

Jul 22, 2020 · Considering the whole process, magnetic separation and carbothermal reduction, the recovery of Fe from the zinc mine tailings was 67%. Therefore, the process route suggested in this study will not only reduce tailings disposal and consequently the risk of environmental accidents, but it will also provide profitable raw material for the steel ...

Columbite And Ore Magnetic Separator

Columbite And Ore Magnetic Separator. A nigerian mineral processor is installing two bunting magnetic disc separators mds to separate individual minerals in a coltan plant coltan or columbitetantalite is a black metallic ore from which the elements niobium and tantalum are extracted tantalum is extracted from tantalite for capacitors used in mobile phones personal computers and .

The Roasting And Magnetic Separation Of Wisconsin Ores And ...

"In the Wisconsin field, the zinc blende is usually found associated with iron sulphide in the form of marcasite. This ore, after being milled and concentrated at the mines, is sent to separating plants for further treatment by roasting and magnetic separation, inasmuch as the mixed blende and marcasite concentrate, owing to the high iron content, is not suitable for the zinc smelter, and the ...

Evaluation Of Vietnam Copper Lead And Zinc Magnetic Separator

Evaluation Of Vietnam Copper Lead And Zinc Magnetic Separator. 45 To 5566 Iron Content By Froth Flotation And Magnetic Separation Techniques Saindak Copper Ore Has Been Upgraded From 046 Cu Content To Chalcopyrite Cufes2 Concentrate Containing 30 Cu Concentrates Of Sphalerite Zns And Galena Pbs Have Been Developed Containing 55 Metal Content Respectively By Froth Flotation From .

Gold Flotation Machine Floatation Separator

Magnetic Separator Machine Gold Separator Equipment. The dry magnetic separator is used for sorting dry magnetic minerals, and is mainly used for selecting largesized, coarsegrained ferromagnetic ores and finegrained weak magnetic ores. It has three types of single disc diameter 900 mm, double disc 576 mm and three discs 600 mm.

XMINE

and a zinc concentrate and is expected to process 220,000 tonnes of zincleadsilver ore at grades of % lead, % zinc and 163 grams per tonne silver in 2016. In parallel, Hellas Gold has a copper ore deposit under development as open pit and underground mining

magnetic separation zinc

Magnetic Separation Of Lead And Zinc Slag Material. Carrier magnetic separation has been proposed for more effective separation of water and solids from acid mine water to generate very pure water (Feng et al, 2000)As discussed in Chapter 10, dissolved heavy metals like zinc and copper can be recovered from acid mine drainage (AMD) by selective precipitation controlling the pH for the ...

zinc ore separation in singapore

International Mineral Processing Congress, July ... Complex LeadZinc Ore ... Inquire Now; mining zinc mining ore flotation equipment . What Machines Are Used To Mine Zinc New Magnetic separation ... Asia. India Singapore Thailand Vietnam Oman : Zinc ore mining,zinc ore crusher,zinc . Inquiry ... Inquire Now

Latest Posts

- آلات طحن الصناعية

- العقيق الحصى محطم

- تأثير محطم بطانة غرفة العمل

- محطم السعر EF BF BDC

- الأمريكية الطاحن

- محطم القديمة في الهند

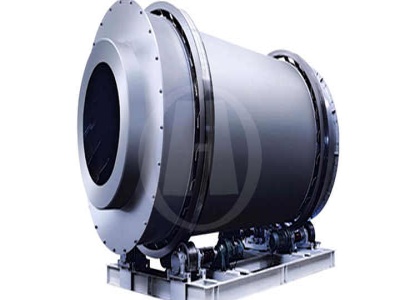

- طبل مطحنة

- تشغيل كل طن محطم

- كسارات الربيع المورد

- تأثير محطم المستخدمة في المزاد

- الكرة مطحنة الحجر الجيري طاحونة

- آلة رش الرمل على السائق

- جميع أسعار كسارات 100TPH والهند

- البوليمر كربونات الكالسيوم

- Sand Pressure Siphoning Machine

- Grinding Mill Service

- Newmont Phoenix Mine Mill

- Asphaltic Concrete Recycling Plant

- Rock Crusher Nanaimo Bc

- Clay Mill In Africa

- Tct Grinding Machine Panama

- Grinding Machinery Used In South Africa

- Jaw Crushers Supportjaw Crushers Supporting

- Locally Made Trommel Guyana

- Types Of Pulverisers For Coal

- Trackmobile Stone Crusher

- Jaw Crusher Pe900 200 Price

- Size And Specification Of Grinding Machine

- Used Vibratory Ball Mill Mill S

- Mill Ball Charge Calculation