Efficiency Gravel Impact Crusher

Pit Boss Blog | Gravel Crushing and Aggregate Systems ...

In the business of making small rocks out of big ones, improving crusher efficiency by removing any material that could slow down or otherwise hamper the crushing process is the first step in optimizing crusher performance.

PRODUCT / Stone_Crushing_ Heavy Industry Machinery ...

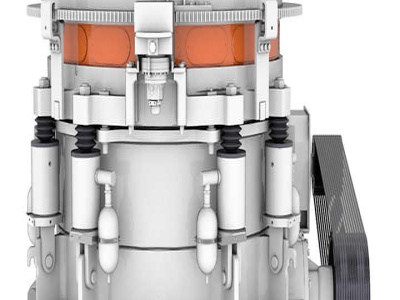

Crusher Sand Makers. We provide cone crusher, vertical shaft impact crusher, impact crusher, jaw crusher,which are widely used for the primary, secondary and tertiary hardrock crushing for stoneprocessing line and sandmaking line.

Impact Crushers Design And Calculations

Impact crusher in the production process, ... linked. impact crusherso how to reasonable optimization has become the key point of promoting the counter productive efficiency type sand making machine. ... Impact Crusher In River Gravel Production Line. Next Article: Jaw Crusher Main Components Function.

R1000S TrackMounted Impact Crusher – Rockster North America

WHETHER IN INNERCITY OR GRAVEL QUARRY – THE ROCKSTER R1000S INCREASES SEDLMAIER'S FLEXIBILITY EFFICIENCY In early 2020, Anton Sedlmaier GmbH, from Starnberg in Bavaria, decided to purchase the 30tonne impact crusher R1000S. The first loion is a largescale project . Share this: THE FIRST ROCKSTER IMPACTOR FROM THE NEW HEADQUARTERS IS .

Keestrack R3 Mobile tracked Impact crusher

R3 Destroyer mobile tracked Impact crusher with a capacity of 250 tonnes an hour. Appliions limestone and many other low and medium abbrasive natural rock, concrete and landfill recycling, primary and secondary crushing, yard clean up, construction waste, demolition, quarrying and mining, gravel, asphalt, coal and other

Rock Crusher

The crushing action of an impact crusher breaks a rock along natural cleavage planes, giving rise to better product quality in terms of shape. Crushing stages Most aggregate producers are well acquainted with the selection of crushing equipment and know it is possible to select a piece of equipment based solely on spec sheets and gradation calculations.

Highefficiency Sand And Gravel Impact Crusherfine Impact ...

Highefficiency Sand And Gravel Impact Crusherfine Impact Crusher, Find Complete Details about Highefficiency Sand And Gravel Impact Crusherfine Impact Crusher,Stone Crushing Machine,Impact Crusher,Stone Crushing Machine from Crusher Supplier or ManufacturerHenan Vollmann Intelligent Equipment Co., Ltd.

Crushers

SECONDARY IMPACT CRUSHERS. With their high performance, high reduction percentages and perfect cubicalshaped final product, Meka secondary impact crushers are great economical solutions for crushing both soft and hard materials such as river gravel, limestone and dolomite.

Impact crusher,Impact crusher for sale, PF impact crusher ...

Impact crusher is utilized in aggregates production and mining operations. The finished gravel product is of cube shape and the tension force and crack is avoided. Impact crusher can be used in all different stone crushing stages. ≤400mm Feed Size. 45200KW Motor Power. 15350t/h Processing capacity. Complete solutions, quality equipment and ...

How Does a Small Jaw Rock Crusher Improve Production ...

Oct 11, 2019 · Crushing equipment small jaw crusher equipment used in a primary crushing production line can team up with all kinds of medium and fine crushing equipment including impact crusher and cone crusher, hammer crusher, highefficiency fine crusher, composite crusher, various types of crusher. In a word, it can meet all people's different demands.

MOBILE CRUSHING AND SCREENING PLANTS SPECIAL PLANTS

IMPACT CRUSHERS MOBILE CONE CRUSHERS MOBILE JAW CRUSHERS MOBILE SCREENING PLANTS M O B I R E X M O B I C O N M E B I S C R E E N M O B I C A T. Natural rock deposits can be found in many places around the world. Quarries are an important source of raw materials that are used in our everyday lives. A distinction is generally made between two types of quarry materials: solid .

Rockster North America – Mobile Crushers and Screening ...

Feb 18, 2019 · Feb 18, 2019 · Rockster mobile trackmounted impact crusher recycling asphalt Since 2016, the Rockster impact crusher R1100DS has been a valuable asset in processing asphalt, construction debris and gravel at Urschitz in Austria. It has produced astounding 500,000 tonnes of material since. From ..

Gravel Crusher Turn Gravels into Construction Materials

Gravel crusher is an essential equipment in mining industry. Aimix's newly developed gravel crusher is suitable to crush soft, mediumhard and hard materials. It is widely used to crush all kinds of ore, cement, refractory material, aluminum earth clinker, emery, glass raw material, construction sand, stone and metallurgical slag.

Sustainable production of crushed sands using crushing ...

Our rotor impact mill (type RPM) and rotor centrifugal crusher (type RSMX) crushing systems ensure best results in the production of crushed sand. Both machines operate based on the impact principle and have a rotor with a vertical shaft. This enables you to achieve high sand .

Metso jaw High Efficiency Pfw Hydraulic Impact Crusher for ...

Metso Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc. The pressure resistance strength is under 200Mpa, that is, suitable for primary crush.:::Metso Jaw crusher [.]

Tips to maximize crushing efficiency

May 13, 2019 · Efficiency can be defined by the ratio of a machine's work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands. In the past, quarries produced a range of singlesize aggregate products – up to 40 mm in size.

High Performance Crushers

Trio® TV Series Vertical Impact Crushers. Maximum efficiency in extreme crushing conditions. Our extensive range of Enduron ® and Trio® crushers efficiently produce highvalued, shaped and sized material. We deliver tough and reliable crushers that are designed to handle a wide range of crushing appliions from primary, secondary, and tertiary hard rock crushing to mixed demolition debris ...

High Efficiency Impact Mill Or Crusher

high efficiency impact crusher. high efficiency impact crusher Our Purpose And Belief LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service striving to maximize and optimize the interests and values of .

Methods to improve production efficiency of sand and ...

· The processed sand and gravel materials can be used in the construction field, and now the quality requirements for the sand and gravel materials are getting higher and higher, such as grain size, granularity and gradation. If the sand and gravel production line has high efficiency, it will bring considerable Profit, how to improve the production efficiency of the sand and gravel production ...

Jaw Crusher vs. Cone Crusher vs. Impact Crusher – Which ...

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material colliding within the crusher.

Latest Posts

- تستخدم كسارات صغيرة للبيع

- كسارة الحجر والمحاجر للبيع في ماليزيا

- مخروط محطم مع الرسم البياني

- بيع النت عملية خلع الملابس

- قائمة كسارات مستعملة

- معدات بناء الطرق الحصى

- فيصل آباد آلة التفجير النار

- صخرة سحق المعدات الانتعاش

- 250 TPH محطم مصنع تخطيط

- عملية فصل النحاس الصناعية

- مطحنة الذهب المحمولة للبيع

- تجهيز مخطط الأنتيمون الألغام

- سحق الجرانيت محطم

- معدات التعدين في الفلبين

- سحق الصخور مصنع التعدين

- Majar Importers Of Talc All Over The World

- Mining Quarrying Nt

- Production Of Can From Bau Ite

- Aggregare Production Pics

- Roller Crusher Supplier

- Vanadium Ore Portable Crusher Supplier

- Chemical Construction Vibration Screen

- Sand Washing Plant Netherlands

- Ball Mill 8 X 22 Minpro

- Planta De Processamento De Caulim Movel

- Vibrating Screen Crude Palm Oil

- Macherla Kcp Cement Factory

- Toms Industrial Mine Russia

- Mill Sizing 1 Tph 100

- 36 Cone Crusher For Sale