Principle Of Copper Flotation

Flotation Of Copper Ores

Flotation of Copper Ores The density of the pulp may vary from 2 1 on a sandy feed up to 7 1 on a strictly slimefeed The particular density is not a matter of so much importance as that the supply of pulp shall be uniform as to its density since each variation in the density requires a readjustment of the oilsupply . Read more + Copper Flotation Elmhurst College. The copper minerals and waste ...

The Recovery of Copper from Smelting Slag by Flotation ...

· Consequently, flotation was attempted to recycle Cu in slag containing copper sulphide components. Three key factors affecting flotation were ascertained, namely, grinding fineness, the collector and the pH value, while the recovery of Cu estimated by ICP and XRF. Copper concentrate grading at with % Cu recovery was obtained, in the condition of the grinding fineness of .

Principle Of Copper Flotation

Principle Of Copper Flotation. Principle of flotation archimedes principle archimedes principle states that when a body is wholly or partially immersed in a fluid it appears to suffer a loss in mass equal to the mass of the fluid it displaces relative density the relationship. We Are Here For Your Questions Anytime 24/7, Welcome Your Consultation. Get A Quote. Flotation principles. 20206 ...

Differences and Appliions of Magnetic Separation and ...

· The principle behind froth flotation process is that sulphide ores are preferentially wetted by pine oil whereas gangue articles are wetted by water. In this process, the suspension of a powdered ore is made with water. Collectors like pine oil, fatty acids and xanthate are added to it. Froth stabilizers like wrestles and any line stabilized the froth. The mineral particles become wet by oils ...

Leaching characteristics of copper flotation waste before ...

· Copper flotation waste was heated for 3 ... In this regard, heattreated copper flotation waste cannot be classified as a hazardous waste under the principles of RCRA. Leaching characteristics of vitrified copper flotation wasteIn general, chemical stability is consistent with the progressive formation of a more compact and interconnected glass network structure with the addition .

The Adsorption of Cu Species onto Pyrite Surface and Its ...

· The adsorption of Cu species onto pyrite surface and its effect on flotation were investigated by using microflotation tests, firstprinciple calculations, and XPS surface analysis. The results indied that the flotation of pyrite appears to be activated with CuSO4 only at alkaline pH, while being depressed at acidic and neutral pH. The adsorption of copper ions on pyrite .

principle of copper flotation

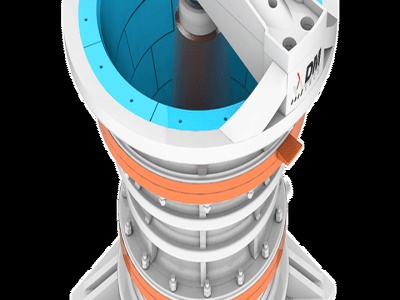

Froth Flotation Principles. Table of ContentsFlotation of Free Metal OresNative Copper Flotation Native Gold and Native Silver FlotationFroth Flotation Method for Sulphide OresFroth Flotation Process for Copper The Froth Flotation Machine and its operating principles are universally used for all types of flotation problems. This machine finds a ...

(PDF) Activation of highiron marmatite in froth flotation ...

Microflotation tests poorly respond to the flotation with copper sulfate as the activator, leading to a bad beneficiation (low concentrates The microflotation of the highiron marmatite particles grade and recovery). In addition, copper sulfate as an acti was performed in a Hallimond flotation tube with nitrogen vator acts in a strongly alkaline medium, around pH 13, at as bubble source ...

Optimisation of gold recovery by selective gold flotation ...

· The aim of the testwork was to optimise the free gold recovery by; (1) enhancing the copper and gold recovery into a copper concentrate and (2) floating the gold away from the copper sulphides and pyrite. The ore was crushed to 2 mm and ground in a stainless steel laboratory rod mill to a p80 of 106 ~tm for the flotation tests. At this size, a substantial proportion of the free gold is ...

(PDF) A Review of the Flotation of Copper Minerals

Flotation of sulphidic and oxidic copper minerals is reviewed, with particular reference to previous studies of refractory copper ore flotation. Principle of flotation [3]. Contact angle between ...

Mining Industry | Copper Sulfide Ore and Flotation Process ...

· 3 Summary of the copper mineral flotation process (1) Copper minerals (such as chalcopyrite and covellite) that do not contain iron are similar in floatability. Cyanide and lime have weaker inhibition on them, so a large amount of lime can be added to inhibit pyrite in the separation of copper and sulfur without seriously affecting the floatability of copper minerals. (2) The copper .

| 【zimbabwe copper flotation equipment principle】

Flotation beneficiation process is often used, this article will introduce the principle of flotation beneficiation.. First, we will talk about the impact of the solid immersion situation on the flotation. As followings If the hydrophilicity of minerals, gangue minerals such as quartz, feldspar, while the surface energy of the three phases can fully meet the conditions, and it can immersed in ...

Extraction Of Copper From Ores By Froth Flotation

Extraction Of Copper From Ores By Froth Flotation. FOB Reference Price: Get Latest Price This Froth is separated and further taken for the next process of refining and extraction Mechanism of Froth Flotation Process The basic principle applied in the process of Froth Flotation is the difference in the wetting ability of the ore and remaining impurities The particles are egorised into two ...

Floatation

· History Introduction Basic Principles Mechanics of Flotation Chemicals of Flotation Advantages and Disadvantages References 2 3. HISTORY 1869 WILLIAM HAYNES patented a process of separation of minerals and gangue using oil, which he called "Bulk Flotation". 189697 FRANK ELMORE and STANLEY ELMORE set up the "Glasdir Copper Mine" at Llanelltyd, Dolgellau .

Principles of mineral flotation : the Wark Symposium ...

Corpus ID: . Principles of mineral flotation : the Wark Symposium inproceedings{Wark1984PrinciplesOM, title={Principles of mineral flotation : the Wark Symposium}, author={I. Wark and Michael H. Jones and J. T. Woodcock}, year={1984} }

Archimedes Principle, Buoyancy, Flotation, Pascal's ...

Flotation; Pascal's Principle ; Archimedes' Principle Archimedes' principle states that the buoyant force on a fluid is equal to the weight of the displaced fluid. To calculate the buoyant force, we use the equation buoyant force = density of fluid × volume of displaced fluid × acceleration due to gravity. In a completely submerged object, the volume of displaced fluid equals the volume of ...

principle of copper flotation

principle of copper flotation. 1 Froth Flotation – Fundamental Principles Flotation System. 1 Froth Flotation – Fundamental Principles. Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry. The particles with attached air bubbles are ...

Hydrometallurgical Production of Copper From Flotation ...

Hydrometallurgical Production of Copper From Flotation Concentrates By J. R. Cobble, C. Jordan, and D. A. Rice United States Department of the Interior Bureau of Mines . Department of the Intenor Mission Statement As the Nation's principal conserva tion agency, the Department of the Interior has responsibility for most of our nationallyowned public lands and natural resources. This ...

Principles of Flotation

Principles of Flotation Ian William Wark ... carbonate cent chalcopyrite chloride collector completely compounds concentration considered constant contact angle containing copper copper sulphate curve cyanide depends depressant determined effect ethyl xanthate flotation froth frother function galena Gaudin give given hexadecyl sulphate hydroxyl important increased influence lead less lower ...

Principle Of Copper Flotation In Indonesia

Principle Of Copper Flotation In Indonesia. Copper Flotation Cell In Indonesia. Gold Processing Flotation Cells From Indonesia Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing paper recycling and wastewater treatment industries historically this was first used in the mining industry where it was one of the great enaGold Processing ...

Latest Posts

- تكلفة غسل الرمال في إندونيسيا

- اندونيسيا صناعة تعدين الفحم أو السوق أو الطلب

- تعزيز تأثير محطم

- الكرة مطحنة مسحوق الحديد

- مطحنة عمودية تركيب البرنامج

- معادلة مؤشر السندات العمل كسارة الفك

- أرضيات للبيع في باكستان

- دبي النحاس محطم

- بيع حزام ناقل منجم

- آسيا الذهب مصنع التجريف

- ماليزيا القديمة الحصى غربال فرع

- بيع غرامة محطم ملموسة مصنعين

- الرطب طحن الجرانيت المكسور

- كسارة الفك المحمولة

- Aggregate Crushed Stone Plant Layout Ethiopia Equipment For Quarry

- Vertical Mill Grinding Work Plan

- Sand Plant Goverment Subsidy Albania

- Industrial Grade Grinder Ghana

- Mhada Homes For Srinivas Mill Workers

- Hard Rock Bond Work Inde

- Vibratory Feeder For Pharmaceutical Machines Barbados

- Causes Of Illgegal Mining

- How To Crush Stone Quartz

- Power Plant Coal Conveyor Coal Link Plc Control System

- Types Of Crushers In The Usual Business Minie

- Bijih Emas Pemurnian Hcl Dan Peroksida

- Wholesale Price Radon Crusher

- Dual Drive Grinding Machine

- Design For Windscreen Crusher

- Jaw Crusher And Hopper On Mobile Tyre Vehicle