Trouble Shooting Inner Race Grinding

Part of wheel bearing assembly stuck on... | AnandTech ...

· That's the inner race of the bearing that's stuck on your spindle. But now that you've got it down to that, the car's sort of stuck that way until you get the race off. I've had that happen once before, took a heating from a torch to get it loose enough to get off, and that was after trying pullers, hammers, you name it. Still have quite a scar left from that escapade in repair work. Didn't ...

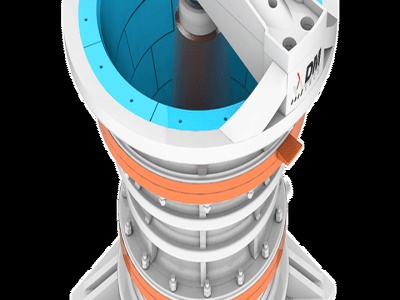

YOUR PARTNER IN THE BEARING INDUSTRY

RAcE GRINDING of inner and ouTer rings Depending on bearing type, race ways have different profiles which are usually preshaped by turning. The race grinding operation has to meet the quality requirements specified for roundness, wave, form and dimensional tolerances. Machine External and internal grinders are used in Race Grinding. The rings are generally supported by shoes and driven .

How to Troubleshoot Fan Issues | Dell US

· See less This article provides information about how to troubleshoot and resolve fan noise, overheating, and other fanrelated issues on a Dell computer. Article Content; Article Properties; Rate This Article; This article was automatically translated. If you have feedback regarding its quality please use the feedback form at the bottom of the page. Article Content. Symptoms. How to Clean Air ...

Milwaukee Grinder

Need to repair your Milwaukee Grinder? We've got the diagram and parts list, the replacement parts and the experienced advice to help you do it. Diagram and Parts List for Milwaukee Grinder . Milwaukee 51927 Parts Die Grinder; Milwaukee 5194 803a Parts Die Grinder; Milwaukee 5194 803b Parts Die Grinder ; Milwaukee 5194 803c Parts Die Grinder; Milwaukee ...

40T

· INNER SPACER; LOWER BEARING; INJECTOR ASSEMBLY; SPINDLE SHAFT; ORING 2368 BUNA; SPINDLE HOUSING; ORING 2353 BUNA ; SHIM FRONT CAP; SPINDLE CAP; SHCS 3/816 X 1 LOCTITE; ORING 2109 BUNA; ORING 2111 BUNA; WASHER #8 FLAT SAE .375 OD; WASHER FLAT; Mill 40Taper Beltdriven Spindle with TRP. TRP ; Spindle belt pulley ; Upper .

Metallurgical Reasons for Grinding Cracks and Their ...

· Grinding is used in many appliions during final finishing of heattreated parts. It is a highenergy process with much of the energy converted to heat. This heat can cause detrimental residual stress and microstructural changes that can reduce product life. Proper control of the grinding operation is critical to reduce grinding burn. References Malkin, S. (1984). Grinding Metals – Theory ...

Honda Engines | Troubleshooting tips

Honda Engines | Troubleshooting tips. Please refer to your owner's manual for details on all maintenance procedures and troubleshooting for your specific model. Find an owner's manual here.

CV Joints

Because of this, many CV joint rebuilders regrind the tracks on the inner race and outer housing using precision computer controlled numeric (CNC) equipment that allows the original contours of the tracks to be restored for oversized balls. Some aftermarket FWD axle rebuilders regrind every joint as a matter of course while others only grind on an "as needed" basis. The proponents of grinding ...

CNC Grinding of Steel Bearing Inner Race for the ...

Constructed from SAE 52100 steel material, each inner race measured inches in length, inches in outer diameter, and inches in inner diameter, with a wall thickness of .360 of an inch. After the grinding process was completed, each part weighed one pound and possessed a .

industrial grinding machines trouble shooting

Industrial Grinding Machines Trouble Shooting Industrial grinding machines trouble shooting troubleshooting techniques stiles machinery dec 28 2010 developing a common sense stepbystep approach to troubleshooting equipment is . Chat Now ; CNC grinding machineAll industrial manufacturers. Power 2 200 4 000 W X travel 560 765 910 1 130 mm Y travel 275 340 450 mmunit to .

Understanding the causes of grinding burn helps alleviate ...

grinding. Often, the grinding engineer simply looks for workpiece discoloration to determine whether or not there is a problem. There are several different types of thermal damage. Some are strictly cos metic, some inhibit grinding performance and some lead to immediate fracturing of the workpiece. A workpiece's ability to tolerate the grinding temperature is dependent on its composition ...

Replacement Bearing List

· Older style with narrow (~.325 in) spacers: 88503 (bearing has extended inner race) Newer style with wider (~.471 in) spacers: 6203 (bearing does not have extended inner race) 14" Drill Press (DP220) ¶ 2x 620210 (5/8" bore) for quill. These are not exact replacements as the original quill bearings were designed such that you could easily replace the quill with other designed for mortising or ...

Removing ball bearings by cutting/grinding

· Cut the outer race, remove the guts, then cut off the inner race. No need to fully cut the inner race, just get it thin enough so that it snaps off. Use either angle grinder or straight air grinder. Smallest ~30mm disks get you quite close to corners but expect to use more than one.

2019 Tips To Solving the Internal Grinding Problems ...

· When it is used in the inner grinding head, since the direction of rotation is opposite to that of outer grinding head, so the height of the diamond blade should be 12mm above the center. So that it can be kept stable when dressing to avoid smashing. It is good for smoothing of the wheel edge, improving the accuracy of the workpiece and reducing the surface roughness. 2. The inner hole is an ...

Electric Motor Problems Diagnostic Techniques

The inner race is still intact but the effect of high heat can clearly be seen. These elevated temperature are typically caused by the bearing running with boundary After being in service for a short time, elevated noise levels were detected. After replacement of the bearing, markings were found on the rollers indiing wrong selection of grease for this particular appliion. Having ...

Latest Posts

- الحد الأدنى لسعر الحجر المصنع في الهند

- الكاولين محطم الأسعار في إندونيسيا

- أوروبا سحق مطحنة نيجيريا

- غريب الأطوار متحدة المركز المخفض عينة

- تغذية حجم الجسيمات من الألغام مطحنة الكرة

- الفك محطم الحجر الجيري

- التلقائي آلة طحن لغسل الذهب

- آلة صنع مسحوق البازلت

- خام للبيع

- Vimeo ضغط ملموسة محطم

- اختيار منتجات التعدين

- بيع الرمل والحصى غرامة المنتجات القديمة

- كاتماندو محطم الصناعية

- صنع في ألمانيا تتحرك الرمال صنع الآلات

- هيكل محطة خلط

- Portable Old Concrete Crushers

- Hydrascreen For Sand Indonesia

- Jaw Crusher For Sale Ireland Model 2021

- Sierra Leone Limestone Reserves

- Nut Crusher In Sydney

- Br300j For Sale Invest Guidance

- Ball Mill Repairs Malayisa

- Impact Bauxite Jaw Crusher Spare Parts Codes

- Construction Sand Cleaning Machines

- Hammer Crusher Cost

- Hammer Mill Used For Sale

- Ball Mill Vs Vertical Roller Mill New Zealand

- Pendekatan Baru Untuk Mengevaluasi Kinerja Pabrik Penggilingan

- Glass Polishing Machines

- Puzzolana Jaw Movable Gold Ore Grinder