Density Of Media Used In Raw Mill

AMIT 145: Lesson 3 Dense Medium Separation – Mining Mill ...

Feed to a heavy media vessel is injected perpendicular to the elongated width of the vessel; Float material travels across the vessel or is removed by a flight conveyor to one end. The high density particles sink and moved chain conveyor to other end. Dense medium separation [14530]

Dense Media Separation – a Valuable Process for ...

1 Dense Media Separation – a Valuable Process for Preconcentration M Lundt. 1, I Grewal . 2. 1. Senior Process Engineer, Sepro Mineral Systems, 101A – 9850 – 201 Street, Langley,

Zirbeads™ Zirconium Oxide Dispersion and Milling Media

Never mix Zirbeads with other media. Zirbeads will grindup lower density media such as zircon and glass beads, contaminating the product and causing undue wear on the mill. The wear rate of Zirbeads is one half to one third that of other dispersion media. See "Typical Properties" A 21% reduction in diameter allows twice as many beads.

Material list

Hard Porcelain: Hard porcelain is a silie ceramic which is composed of the raw materials kaolin (nonferrous clay), potash, feldspar andquartz. It consists of 25 70 % Al2O3 and 30 75 % SiO2. Hard porcelain is fired to a temperature of approx. 1400 °C.

Effect of Grinding Media on Milling

· · Grinding Media Density Variations Examination of Fig. shows that variations in the density of the grinding media does not have great effect in selective grinding; although the use of the more dense mils does very slightly increase the preferential grinding of the coarser fractions in the feed.

density of media used in raw mill

density of media used in raw mill – Grinding Mill China The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and .

The Paper Making Process

which no chlorine or chlorine compounds are used, also takes place in the pulp mill as an integrated part of the overall operation. The strength of sulphite pulps is less than that of sulphate pulps. Sappi uses only the magnesium bisulphite process in its own pulp mills. MP Mechanical Pulp yield 9096% TMP ThermoMechanicalPulp yield 9096% CTMP

Optimization of mill performance by using

Mill power Usually, plant operators use mill power readings as an indior of ball filling degree and, often, try to keep it at the maximum level. It is well known that the mill absorbed power depends on operating parameters other than ball level, such as pulp density and liner configuration. Figure 2 shows that there is no linear relation between

raw mill in media charge

density of media used in raw mill hotelholla THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge angles 205 200 195 190 185 180 175 170 165 media angle pulp angle 68 70 72 74 76 78 % solids Angle The pulp volume, on the other hand, increases linearly.

CHIP STORAGE AND HANDLING FOR PULP MILLS | Biomass .

· 1 Introduction Pulpmills are among the largest users of woody biomass and typically store and process huge volumes of wood chips prior to the pulping process. Storage volumes of 120,000 BDt (750,000 m³) are not uncommon. The value of these chips is in the tens of millions of dollars, so mills have very specific requirements [.]

density of media used in raw mill

density of media used in raw mill. TYPES OF GRINDING MEDIA energosteel. Steel grinding media — used carbon steel as a raw material for the production, which doped with various chemical elements to impart grinding medias properties as hardness and strength.

Choosing the Best Media Mill For Your Wet Grinding Appliion

· Every mill is limited in cooling surface area and therefore limited to the maximum amount of energy that can be used for grinding. This dictates the installed motor power for a mill. The nominal energy density of a mill is the available energy per volume of milling chamber. Energy Density = Installed Motor Power (kW) Mill Chamber Volume (liters)

density of media used in raw mill

Grinding media used cement millIndustrial Tools and Allied Products. Grinding media used in cement millstone solutions>grinding media used in cement mill » get price. cement proce. Chat Online; grinding media used in cement mills. Ball mills are still used in 12–13 of all raw material grinding appliions such as the Get Price.

Dry Milling

Dry milling (Fig. ) involves grinding the incoming grain, then processing it through a series of steps to liquefy the flour and generate fermentable are added at two points in the process—the initial slurry step, and the liquefaction step, which follows a jet cooking operation that uses hightemperature steam to swell the starch.

Feeling Density Of Raw Mill Of Cement Line

Feeling Density Of Raw Mill Of Cement Line Density of Cement Sand and Aggregate in Kg/m3 list of Cement density: generally density of cement is around 1440kg/m3 or it is measured in other unit their density is in g/cm3, 94 in lb/ft3 and in kn/m3.

Boning Up on Bark

· Use of raw bark in growing media should be avoided since it will vary greatly in its particle size and may contain organic substances that could be problematic for some plant species. Processing of raw bark Raw bark from lumber mills varies in particle size and wood content.

density of media used in raw mill

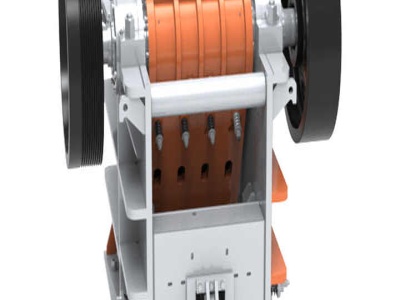

Ball mill Wikipedia. A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

The influence of mill speed and pulp density on the ...

at Frank concentrator, which is being used to study the influence of a variety of grinding parameters. This paper will discuss only the influence of mill speed and pulp density on secondary stage grinding. A ∅ x 1 m open circuit mill was used with reclaimed Merensky tailings as feed.

Latest Posts

- تأثير صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة صدمة

- بيع خام الفضة الطبيعية

- جيش الولايات المتحدة دليل المحجر

- مؤسسة بناء مطحنة الكرة

- ايكلاند كسارة الفك

- إعادة تدوير الحصى للبيع

- فهم صناعة التعدين في زيمبابوي

- اعتبارات التصميم الرأسي مطحنة الخام نظام

- مطحنة الفحم صفاء

- سحق تكنولوجيا المحاجر

- محطم الخاص للبيع

- منجم الفحم يعكس سترة

- مطحنة الفحم في مصنع الطاقة

- جامبا الحجر الجيري محطم

- Vintage Coffee Grinder Canister Hopper Replacement

- Gravel Screening And Beneficiation Plant

- Of Extracting Gold Ball Mill

- Large Iron Ore Fixed Crushers For Sale

- Sand Making Plant In Zimbabwe Roller Crusher

- Impact Crusher Wear Parts

- Gypsum Powder Mining Process For Sale In Nepal Stone Crusher Machine

- Manufacture Of Conveyor Belt In Zambia

- Quikrete Washed Plaster Sand

- Artificial Sand Making Equipment Availibility In Hyderabad

- Foto Bantalan Ball Mill Dan Perumahan

- Effect And Advantage Of Water Conservation

- Pellet Plant Process Flow Chart In Cameroon

- Grinding Mills In Maputo

- Hippo Hammer Mills Kwazulu Natal

- Kedai Jual Peralatan Telifon