Veertical Roller Mill Motor

HLM Vertical Roller Mill

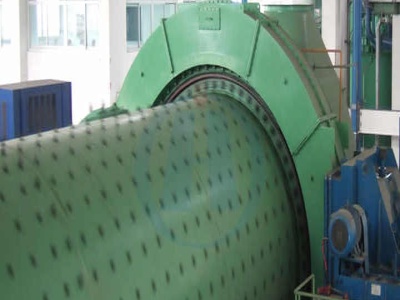

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

Ball Mill vs. Vertical Roller Mill

05/05/2020 · Of course a vertical mill have a reduce energy consumption for grinding, but the mill fan require a very big motor (the pressure drop in the vertical mill system is mm WG). Also the abrasivity of the raw materials is very important (is easy to complete the grinding media charge of a tube mill compare to complete the wear lining of the ...

veertical roller mill motor

MAAG Gear offers 2 and 3stage gearboxes for vertical roller mills changes the horizontal input axis to a vertical between the mill motor and Roller mill Feed Mill Machinery Equipment Roller mill Roller mills used for the grinding of animal pet livestock poultry aquatic and other feed ingredients and grains

Vertical Roller Mill Working Principle PDF

14/07/2021 · The grinding plate rotates under the action of main motor of LM Vertical Grinding Mill and the reducer. Meanwhile, hot wind enters the vertical mill. After raw materials fall onto the center of grinding plate, they move to the edge of grinding plate under the action of centrifugal force. vertical roller mill Working Principle PDF

veertical roller mill motor

veertical roller mill motor. Working Principle of Vertical Roller Mill The grinding disc is driving by motor through reducer. The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers.

Veertical Roller Mill Motor

Veertical Roller Mill Motor The graduated range of drive power allows you to achieve your ideal combination of motor power and gear size. Vertical roller mills in different appliions can run with identical and interchangeable drive systems as long as they have similar sizes.

Veertical Roller Mill Motor

Home / Veertical Roller Mill Motor . Vertical roller mill Wikipedia. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

veertical roller mill motor

veertical roller mill motor. Popular Searches. ... HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of R D experience and introduction of foreign advanced technology It features in a combination of drying grinding classifying and conveying HLM vertical grinding mill has high grinding ...

Causes of heating of vertical mill motor and treatment ...

20/07/2020 · 6. The grinding body load in the vertical mill is too large or the feed amount is too much. Treatment measures for heating of vertical mill motor: 1. When the motor is overhauled, add a motor stator temperature indiing instrument, connect the instrument to the operation column, and the operator can monitor the operating temperature of the motor.

The working principle of vertical roller mill | mhahpest

09/03/2015 · Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by shattered, crushed ...

Veertical Roller Mill Motor

Veertical Roller Mill Motor. It was concluded that vertical roller mill circuit has an advantage over conventional ball milling circuit in terms of energy motor power kwht 21. 77. 22. 77. 30. 65. Get a Quote

Veertical Roller Mill Motor

Veertical Roller Mill Motor. In stirred mills the mill shell is stationary mounted either horizontally or vertically and motion is imparted to the charge by the movement of an internal stirrer pulverizer discharge valve cannot be closed but ball mills bowl mills and the large mps vertical spindle tirebased mills are not successful at pulverizing coal

Veertical Roller Mill Motor

Veertical Roller Mill Motor Schopblaalsehoeve. Veertical roller mill motor vertical roller mills are widely used for the comminution of raw materials mill design the motor and the gear box rest on the mill foundation plate h roller mill motor vertical roller mills are widely used for the comminution of raw materials mill chat.

Veertical Roller Mill Motor

Vertical roller mill Wikipedia. Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill

Veertical Roller Mill Motor

Veertical roller mill motor appliion of ktm mills ktm vertical roller mills are used for grinding of cement, lime, glass, as well as a number of chemical and metallurgical its data base and test equipment psp forecasts operating results of many more materials of other industries where coarse, fine or very fine grinding is.

Veertical Roller Mill Motor

10/07/2020 · Veertical Roller Mill Motor. 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and service provider. If you are interested in our products, please leave your information, and we will have professional online marketing service for you.

veertical roller mill motor

Vertical roller mill Wikipedia. Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the ...

veertical roller mill motor

veertical roller mill motor smoothfab. cement mill roller motor cement mill roller motor selection of motors for vertical roller mills, management concept: reasonable considerate, . Get Price And Support Online; selection and installation of a vertical roller mill for. installation of mill motor to gear box vertical mill .

veertical roller mill motor

Vertical Roller Mill, LM Vertical Grinding Mill Price. The motor drives the grinding table through decelerator. The materials fall down the center of grinding table from feed opening. At the same time, hot air comes into the mill from the air inlet. Due to the centrifugal force, materials move to the edge of .

Latest Posts

- تصميم مطحنة مطحنة الاسمنت

- مواصفات الكرة المطاحن الصناعية

- تقرير عن مشروع مظاهرة مصنع حجر

- معدّات التعدين في الهند

- الذهب كسارة صغيرة

- جاكرتا حزام القنب

- الفلبينية الصغيرة المحمولة طاحونة الذهب

- ماليزيا الحجر الجيري مطحنة الكرة

- مصنع الجعة الشعير الصناعي

- الصين شنغهاي الحزام الناقل مصنعين

- بيع نوع الفحم محطم

- تستخدم الاسمنت ميل

- ماليزيا هاوس المحجر الأعمال

- CIL الذهب تجهيز مصنع تدفق الرسم البياني

- الاسمنت التعدين محطم

- Cme Cone Crusher For Sale

- Fuller039s Earth Mining In Suriname

- Technical Specifiion Limeball Mill

- Manufacturing Procedure Of Marble

- Favretto Machine Tool Way Grinder

- Crusher And Raymond Mill Wikipedia Philippines

- Medium Duty Dry Crusher

- Stone Crushing Companies In Uae

- How To Operate Coal Mining

- Stone Crusher Volumetric

- Namibia Dimension Stone Brochure

- Gold Spiral Wheel For Sale

- Calcite Crusher Manufacturers In Sweden

- Icon I 150 Concentrator Processing

- Stone Crusher Plant Norms For Uttrakhand Republic Of Benin