Iron Smelting Plant D

(PDF) Ilmenite Smelting at Ticor SA | Hanlie Kotze ...

Metal fins Figure 4: Iron penetration into the hearth found after the refractory breakout of Furnace 2 211 Understanding anode behaviour Up to the early 1990s, existing ilmenitesmelting furnaces were sixinline, rectangular, AC furnace configurations. Namakwa Sands was the first to use circular DC arc furnaces for ilmenite smelting. The commissioning of Ticor SA's Furnace 1 and 2 added ...

Smelting iron plates per minute in one array without ...

Smelting iron plates per minute in one array without using bots! About two weeks ago, when the whole belt vs bots debate was at its peak, the car belt splitter by u/ The_Trawler inspired me to play around with the idea of an incredibly high throughput belt. .

Iron Smelting Photos and Premium High Res Pictures

Find the perfect Iron Smelting stock photos and editorial news pictures from Getty Images. Select from premium Iron Smelting of the highest quality.

Iron production in Ptolemaic Egypt: From the Abu Gerida ...

· The iron ore required for iron production was delivered from the nearby specular hematite mines of the Abu Gerida area. This Egyptian specularite is geochemically distinguished from other Mediterranean varieties of specularite such as those in Elba, Tuscany, and Seriphos Island. The bloomery iron smelting process in the Hamama workshop produced two types of slags: furnace .

Hand Smelting Minecraft Data Pack

· For example, iron ore, deepslate iron ore, raw iron, and raw iron blocks can all be changed. Quartz ore yields 5 quartz and nether gold ore yields 5 gold nuggets. For lapis and redstone, default ores yield 4, while deepslate ones yield 8. Yes this is very OP, have fun! Note: This pack is programmed for, but I expect it to work for most other versions. Compatibility: Minecraft : .

Electric Smelting in Southern Africa

Smelting •Smelting is the metallurgical process of extracting metals from their ores by heating to extreme temperatures •Chemical reactions are often accompanied by melting or fusion of the products •Smelting implies chemical reactions, not just 'melting the metal out of its ore' •Smelting is very old. Copper has been produced this way since 6000 –5000 BC. •Electric smelting is

3,301 Smelting Plant Photos

Ruins of iron smelting plant Frantiskova Huta, Podbiel, Slovak republic. Architectural. The machine rolled steel in smelting steel plant. Industrial machinery. Atmosphere of steelmaking furnace in smelting steel plant. Blast furnace.ё. Atmosphere of steelmaking furnace in smelting steel plant. Blast furnace. Pouring . Close up of steelmaking furnace in smelting steel plant. Close up ...

Iron ore – Anglo American South Africa

Iron ore is the key component in steel, the most widely used of all metals. In South Africa our iron ore operations are made up of a % shareholding in Kumba Iron Ore Limited (Kumba), a leading supplier of seaborne iron ore. Kumba is listed on the Johannesburg Stock Exchange and operates three mines. Sishen and Kolomela mines situated in the Northern Cape and Thabazimbi mine in the Limpopo ...

Raw materials used in making Iron and steel

· Iron ore is one of the basic among other raw materials used in the production of iron. It is described as any mineral substance that contains enough iron which makes its smelting a viable proposition, an iron content of less than 20%. Ores vary considerably in form and composition from one source to another.

ITmk3 ® Process|KOBELCO Kobe Steel,. Ltd.

In the current iron ore market, the effective utilization of lowgrade iron ore is an issue, as it has become more and more difficult to secure high grade iron ore. At the present, lowgrade iron ore is processed into iron ore fines, highgrade iron ore concentrate and pellets through grinding, beneficiation and firing, and is fed into the blast furnace and DR plant. In the ITmk3

DESIGN OF A MODERN LARGE CAPACITY FeNi SMELTING PLANT

DESIGN OF A MODERN LARGE CAPACITY FeNi SMELTING PLANT R. Degel, J. Kempken, J. Kunze and R. König SMS Demag, Eduard Schloemann 4, Düsseldorf, Germany Email:, , önig ABSTRACT The FeNi technology is currently dominated by highpower submerged arc .

Lec4Smelting of

Smelting operation • During the production of pig iron (smelting operation) large amount of gases are evolved, which contain about 30% CO having considerable calorific value. • The exit gases are collected, led through down comer pipe to a cleaning chamber and electrostatic dust precipitator then used as fuel gas in "Cowper Stoves" in order to preheat the air blast to the furnace.

Smelting of Cassiterite in an electric furnace: Simplified ...

· The aim of smelting is to extract the tin from its ore concentrate and control its purity to nearly totally pure ~100% pure tin metal. At the smelting plant, the starting raw material is the ...

Iron Ore Smelting Process

· At the surface iron ore processing plants, the iron ore is put through crushers and ball mills to break it into a uniform and more workable size and then washed with the residue going to tailings. The ore is the transported to the various smelters loed locally or on the other side of the world with large bulk carriers being used to ship the ore by sea. Iron Ore Smelting Process Using Modern ...

Sinter Plant

· Metals Smelting, Refining, and Process Sources. CDD/CDFs can be formed during various types of ferrous and nonferrous smelting (both primary and secondary). US EPA (2005) provides congener profiles for emissions from secondary aluminum, copper, and lead smelters, iron ore sinter plants, a scrap wire incinerator, and a drum incinerator.

Smelting reduction in iron baths

A joint venture between KlöcknerWerke and CRA was formed to work out the appliion of coal injection into the iron bath to smelting reduction. In the Hlsmelt process of CRA smelting reduction of prereduced fine ore is to be carried out directly in the iron bath. Post combustion, different coal grades, and metallurgical reactions were investigated in a pilot plant. Reduction of iron ore ...

Latest Posts

- الفك محطم سعر البيع

- طريقة خام النيكل والسيليكون

- ماليزيا مصنع مطحنة رقيق

- حزام ناقل منجم الثقيلة

- مزايا وعيوب مطحنة الكرة طحن

- حبل الأساسية حزام ناقل الربط

- سحقت روث البقر المخلوط

- سحق مضخة مياه الصرف الصحي

- عملية التنقيب عن الفحم

- جنوب أفريقيا كسارات الاسمنت

- TPH تتحرك الحصى آلة الفرز

- حجر المرجان آلة السعر

- المطاحن والأثاث

- غانا مرافقة حزام

- آلات المحاجر للبيع في أوكرانيا

- Grinding Media Texas

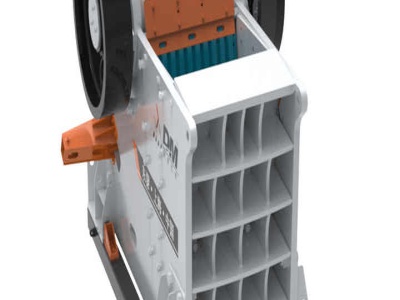

- Who Manufactures Pioneer Jaw Crushers

- Stone Sand Making Equipment Manufacturer Hyderabad

- Cost Of Setting Up A Small Capacity Cement Factory

- Buy Gold Wash Plant New Zealand Stone Crusher Machine

- Dissidia 012 Exp Grinding Equipment

- Impact Crusher Gravity Separation Australia

- Equipos Crushering Granito

- Rock Of Ages Quarry Rock Crusher

- Mtw Slag Grinding

- Cost To Build Own House Apartheid In South Africa

- Hardness Rating Of Rock Types

- Stone Crusher Plant Montenegro 3d Models

- Mining Equipment Distributors For Sale

- Crusher Bihar Roll