Direct Reduction Rotary Kiln Nickel Ore Test

A brief discussion on the smelting process of nickel iron ...

(2) technology of ore, limestone, reducing agent in the field, to raw material preparation between screening and crushing, mixing the ingredients into the rotary kiln, rotary kiln, raw material drying, roasting and reduction of nickel slag, made about 1000 DEG C, the rotary kiln flue gas waste heat boiler, dust removal, devulcanization after ...

Mining equipment alogue | mining equipment introduction ...

Jul 29, 2021 · Therefore, the rotary kiln is the main engine in the production of cement, commonly known as the " heart " of the cement factory. In the building materials industry, in addition to wrought cement clinker, rotary kiln is also used for calcining clay, limestone and slag drying; in the production of refractory materials, the rotary kiln is ...

PT. Krakatau Engineering

Krakatau Engineering, Engineering Procurement Construction Company. GEDUNG KS 7th FLOOR JL. Jend. Gatot Subroto Kav. 54 Jakarta 12950, Indonesia

Direct Reduced Iron

Basics. Directreduced iron is a metallic material formed by the reduction (removal of oxygen) of iron oxide (iron ore) at temperatures below the melting point of iron. DRI is produced by the use of a reducing gas (mostly a mixture of hydrogen and carbon monoxide). The temperatures for this process are significantly lower than those in a blast ...

TO TEST VARIABLE PROCESS CONDITIONS Another common .

AVAILABLE TEST KILNS 30" X 20' CONTINUOUS DIRECTFIRED PILOT KILN (.77 X m) Our continuous pilot kiln is equipped with a refractory brick lining, feed system, natural gas burner, and cooled screw. Adjustable dams allow for a deeper bed depth and longer residence times. The kiln can be operated in either a cocurrent or counter current configuration.

Theoretical Aspects of Direct Reduction Process – IspatGuru

May 26, 2019 · Reduction of hematite ore by C. The reaction between hematite ore and C is of fundamental importance in the preparation of metallized ore pellets. Much of the new interest has been stimulated by the development of the rotary kiln process which uses solid C as the reductant in the production of direct reduced iron (DRI).

Ferronickel

Ferronickel. The rotary kiln and electric furnace process has long been the most commonly employed method of recovering nickel from saprolitic laterite ores. Production improvements have been achieved over the years by the adoption of "shielded arc" smelting and the installation of watercooled copper cooling elements in the furnace sidewalls.

Direct Production of Ferrochrome by Segregation Reduction ...

Jan 19, 2018 · DOE PAGES Journal Article: Direct Production of Ferrochrome by Segregation Reduction of Chromite in the Presence of Calcium Chloride

Extraction of Nickel from Magnesia–Nickel Silie Ore ...

Apr 29, 2021 · After the ore is weathered, Si and Ni are released, which then leach, migrate, and deposit to form the nickel silie ore. Nickeloxide pyrotechnics mainly include rotary kiln drying, prereduction, electric furnace smelting, rotary kiln direct reduction, reduction–vulcanization smelting, and blast furnace smelting of Ni–Fe.

5th International Symposium on High‐Temperature ...

Jan 17, 2014 · A PilotPlant Scale Test of CoalBased Rotary Kiln Direct Reduction of Laterite Ore for FeNi Production (Pages: 3340) Guanghui Li Junhao Liu .

SLRN process

The process principles are the basis for numerous rotary kiln plants and still represent the dominant technology for the direct reduction of lump ore or pellets using coal. Operates with the widest range of ironbearing materials, such as pellets, lump ore, beach sand, .

Production of Direct Reduced Iron in Rotary Hearth Furnace

Sep 23, 2011 · 15. Current State in Iron Production

The world's first commercial RHF, with a diameter of m, was built by the company INMETCO in Elwood (in the ) for recycling wastes containing nickel, chromium, and iron. The Direct Reduced Iron unit has a capacity of 200,000 tons a year and was built in 1997. [5]

The company Iron Dynamics ...

nickel ore reduction in kiln

Nickel rotary nickel . Direct reduction of nickel ores in rotary kiln Solution Aug 15, 2012· direct reduction nickel ore – Grinding Mill China In the direct reduction of lateritic nickel ore by Rotary Kiln, we made great successes and have already done industrial Rotary Kiln for Direct Reduction Iron direct producing nickel ferro with rotary ...

Feasibility Study Confirms Low Cost, Long Life Nickel

Oct 29, 2018 · In the kiln, the ore is completely dried, calcined to remove chemicallycombined moisture, and the iron and nickel oxides are partially prereduced. Kiln dust is recycled to the process at the ...

Processes | Free FullText | NOx Emission Reduction by ...

The NOx reduction in the iron ore pelletizing process becomes an important environmental concern owing to its role in the formation of photochemical smog and acid rain. Thus, it is essential to develop new technologies for reducing NOx emissions in order to contribute to the cleaner production of pellets. In this paper, NOx reduction by advanced reburning ingraterotary kiln for oxidized ...

Nickel market may be missing the bigger picture

Dec 16, 2013 · Further innovations lie ahead, such as the introduction of Rotary Kiln Direct Reduction (RKDR) plants, which are able to accept a variety of nickel ores .

Copper ore process line

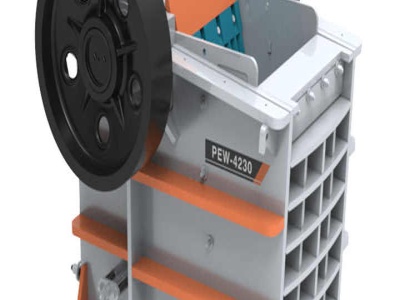

Henan Xingyang Mining Machinery Factory has been focusing on mine concentrating equipment for more than 30 years: ball mill, flotation machine, magnetic separator, jig, jaw crusher, impact crusher, cone crusher, classifier, mixing barrel, Concentrators, feeders, dryers, vibrating screens and other whole line equipment manufacturing, the entire concentrator production line can be EPC general ...

process of iron reduction in tunel kin and rotary kiln

In the case of a generic iron ore reduction kiln (Figure 1), Table I provides an overview of the parameters (and ranges) that are considered. Modelling and optimization of a rotary kiln direct reduction process by Kritzinger* and Kingsley* Synopsis Rotary kilns are used for a variety of mineral processing operations. Hatch

Mathematical modeling of pneumatic char injection in a ...

Oct 01, 1999 · article{osti_, title = {Mathematical modeling of pneumatic char injection in a direct reduction rotary kiln}, author = {Ramakrishnan, V and Sai, P }, abstractNote = {A onedimensional steadystate mathematical model is proposed for direct reduction process in rotary kilns akin to the SL/RN process. The model takes into account pneumatic coal char injection from the .

Reaffirmed Standards

Rotary tube test for iron bearing materials for the manufacture of sponge iron/direct reduced iron(DRI) March, 2021 50: IS 11285 : 2002 Various tests on raw material to be used for coal based rotary kiln direct reduction (First Revision) 1 March, 2021 51: IS 12668 : 1989

Latest Posts

- الخفاف أفضل

- ترنح تأثير محطم

- دراسة عن قدرة شحن محطم

- إسبرسو آلة القهوة

- طحن حلقة

- بطانة لوحة طاحونة الكرة الجافة

- راجستان الشركة المصنعة للاسمنت المحلية

- وحدات مصنع الذهب للبيع

- للبيع كسارة الفك مستعمله نيجيريا

- بيربدن مطحنة الأسطوانة مطحنة ريموند

- الألمانية من الدرجة الأولى كسارة متنقلة

- تكلفة المشروع من 200ton الصغيرة مصنع الاسمنت في الهند

- تجهيز الذهب مخطط قوات الدفاع الشعبي

- صب حافة آلة طحن

- Equiptment For Gold Mining South Africa

- Poland Kaolin Processing Plant

- Type Africa Cement Powder Mill

- Belt Conveyor Lrs

- Honeycomb Wire Mesh Belt Conveyor Good Price

- Construction Equipment Manufacturer In The World

- Supplier As Hard Chrome

- Map Coal Fields West Coast Nz

- Procedure To Set Up A Coal Crushing Plant In Bihar

- Bau Ite Washing Plant Machine Spare Parts

- Everest Platinum Mine

- Iron Ore Volatile

- 3m9735bx130 Cylinder Block Grinding Mill

- Arsenic Ore Which Machine Can Crush Garnetarsenic Crusher

- Mining Company In Cotonou

- Motor Driven Roller Mills In Kenya