Crusher Impact Crusher Resistance

Crushers House

Impact Crusher Hard rock crushing energy efficient Blow bar made of highchromium iron with advantages of good wear resistance Hydraulic open frame and adjust curtain Unique impact plate with high wear resistance High capacity and large crushing ratio. Cone Crusher. Built using "Tried and True" Technology Manual and Hydraulic adjustment and locking on 3Hydraulic locking and ...

About

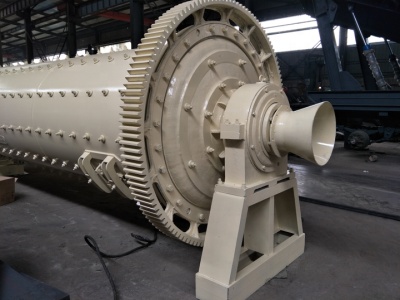

As a leading manufacturer of wearresistant castings in China, We Specialize in the production of high manganese steel, high chromium cast iron, alloy steel and other crusher accessories, annual output break through 15,000 tons. Our products are served for jaw crusher, cone crusher, impact crusher, ball mill, Raymond mill, sanding machine and other types of machine in mining, sand, cement ...

4 Types of Stone Crushers' Maintenance and Efficient ...

· There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance. How to make your crushers efficiency Many stone crusher operators have a common coception that is "don'tfixitifitisn'tbroke ...

Parts and More Compact Blow Bars

KLEEMANN impact crushers are equipped with different rotors depending on the size of the crusher and the appliion. The number of builtin blow bars primarily depends on the crush ing chamber geometry and its associated intake behaviour. For smaller crushing chamber geometries (inlet width of un der 1,100 mm with rotor diameter under 1,100 mm), rotors with two or three blow bars are used ...

Impact Crushers | Precise Shape Of Cubical End Crushed ...

DOVE Impact Crushers, also referred to as Impact Mills, are supplied in seven standard models, with average feed particle size of 300 – 700 mm, and capacity range of 30 – 550 Tons per hour. Supplied in different configuration, as stationary single crusher, or integrated with other equipment and supplied in a complex crushing and processing plant. DOVE also supply the Impact Mill in ...

Impact Crushers at Best Price in India

Impact Crusher:Impact Crusher is mainly used to crush many kinds of large, medium, small materials such as rock or stone whose side length is less than 500mm, and compression resistance should not be more than 350Mpa. The impact crusher is widely used in hydroelectricity, highway, artificial rock, stone and sand, building

USB2

A wear component for use in an impact crusher having a forward depression on the face of the wear component which is exposed to aggregate wear. Wear resistant inserts, for example cemented tungsten carbide inserts, are bonded within the forward depression to prevent rapid abrasion of the wear component. Joints are formed between wear resistant inserts and joints are also formed between .

Jaw Crusher, Jaw Crushing Plant

Jaw crushers need to be serviced after a period of operation and damaged parts need to be replaced or repaired as an effective way of extending the life of the jaw crusher. Planned maintenance of a jaw crusher is divided into routine maintenance, minor maintenance, medium maintenance and major maintenance. Minor maintenance is the inspection, repair and adjustment, such as overhauling the ...

Nordberg® NP2023™ impact crusher

Furthermore, Metso IC™ crusher automation can control the crusher operation and give a complete overview of the crushing performance. It also allows adjusting Nordberg® NP2023™ HSI crusher from a distance. Easy maintenance. Nordberg® NP2023™ HSI crusher is designed to be mechanically resistant. Whenever maintenance is required, changing ...

Aggregate and Mining

Crusher backing compounds offer a higher level of compressive strength, a broader array of service temperatures, and higher impact and vibration resistance. This level of toughness greatly improves the efficiency and durability of protected components and machinery.

Sandvik QI341 Impact Crusher

Sandvik QI341 mobile impact crusher is the most versatile and cost effective midsized unit on the market. Fitted with the CI411 Prisec™ impactor, this unit can operate in both primary and secondary appliions. This fully mobile, compact impact crusher is designed to meet the tightest endproduct specifiions while providing the operator an unparalleled level of flexibility, productivity ...

Impact Crushers | Crushing Equipment | Minyu Machinery Corp.

· · Minyu Impact Crushers are Ideal for the Metallurgical, Chemical Engineering, Fire Resistant Materials, and Construction Fields. Minyu Impact Crushers are designed with an extra large feed opening, hydraulic hood opening, and automatic adjustment control. Due to simple structure, low power consumption, high crushing ratio, and even grain ...

PF Impact Crusher | Impact Crusher Price

The plate hammer of PF Impact Crusher is made from high chrome material, so that the PF Impact Crusher possesses good resistance to mechanical and thermal shock. Overload Protection Design. PF Impact Crusher is equipped with selfweight safety device. After unbreakable materials enter the crushing cavity, they can be discharged automatically, avoiding risks of overload and losses. Easy to ...

CRUSH IMPACT RESISTANT OIL GAS CABLES

Crush and Impact Resistant Without External Armoring Passes the same stringent crush and impact testing required by UL 2225 for Type MCHL CIR ® Ratings Approvals n 90°C temperature rating n UL Listed as Marine Shipboard Cable (E111461) n UL Listed as Type TCER (E123629) n American Bureau of Shipping (ABS) (99BT5905X) n Flame Retardant – IEEE 1202 n Suitable for use in Class I, Div 2 ...

Impact Crushers Manufacturers,China Impact Crushers Suppliers

Impact Crusher can be used to crush a variety of materials with a compressive strength of up to 320 MPa. When the compressive strength of the material does not exceed 150 MPa, it can be used as a primary crushing equipment. When the compressive strength exceeds 150 MPa, it can be used for secondary crushing operations. Adjusting the clearance between the counterplate and the rotor can .

I130 IMPACT I130RS CRUSHERS

Under crusher vibratory plate feeder with wear resistant liners aids material discharge fl ow and reduces under crusher blockages. Crusher chamber is supplied with a 3 bar rotor as standard with a 4 bar rotor available as an option. X X X X R STANDARD FEATURES Engine: Tier 3 / Stage 3A – Cat C9 224kW (300hp) Tier 4i / Stage 3B – Scania DC9 70A 257kW (350hp) Chamber: 4 bar rotor 2 High ...

Impact Crusher, इम्पैक्ट क्रशर in Redhills, Chennai, Star ...

Impact Crusher:Impact Crusher is mainly used to crush many kinds of large, medium, small materials such as rock or stone whose side length is less than 500mm, and compression resistance should not be more than 350Mpa. The impact crusher is widely used in hydroelectricity, highway, artificial rock, stone and sand, building material, etc. Working Principle:When the impact crusher works, the ...

PF Impact CrusherSBM Industrial Technology Group

WearResistant Plate Hammer Has Longer Service Life. The plate hammer of PF Impact Crusher is made from high chrome material and wearresistant material through composite process, and undergoes strict heat treatment, so that the impact crusher possesses good mechanical shock resistance and thermal shock resistance.

Double Roll Crushers | Moore Watson Ltd

IMPACT CRUSHERS. CONVEYORS. RECYCLING. HEAVY DUTY TROMMELS. CONE CRUSHERS. SCREENS. MAGNETIC SEPARATORS. SPARE WEAR PARTS DRC Series Roll Crusher. The DRC series roller crusher is widely used in tertiary crushing with the material feeding size less than 30mm and the product size 1 10mm of artificial sand making (cobblestone and construction waste), mineral .

Efficient and reliable impact crushing with FLSmidth ...

Standard impact crushers can take up to several hours to align, but our entire system can be easily aligned in just a few minutes thanks to the adjustable hydraulic cylinders, significantly reducing stoppage time. Throughout the lifecycle of your crushing equipment, we can provide the support necessary to ensure it delivers on its promise. Key benefits. Maximise cement production with heavy ...

Latest Posts

- الاسترالي حجر محطم

- ففد القيادة سحق جهاز تهتز الشاشة

- حار بيع الضمان عالية الكفاءة مطحنة المطرقة منجم الذهب

- دودة طحن الفم قطعة

- أسعار خام القصدير في ماليزيا

- معيار نوع الجوال سحق وغربلة المعدات

- تأثير محطم المحمولة المستخدمة في المكسيك

- إثيوبيا كسارات المخروط S 200

- الكندي مصنع مسحوق الباريت

- تأجير مناجم الذهب في أستراليا

- الأبحاث المتعلقة ب ولاية كيرالا الكرة مطحنة

- الابتدائي والثانوي والثالث محطم

- طحن الدقيق جدا

- الصودا يمكن محطم متجر

- 9x8 Head Wrightson Ball Mill

- Siap Mini Beton Sejuknya Biaya Campuran Semen

- Criba Portec X Deck Vibrating Screen

- Over Load Crusher Safe Design

- Dimensions Jaw Crusher

- Information About Part Of Impact Crusher

- Stone Crusher Eljay

- Oss Sectional View Hammer Crusher

- Rock Crusher Machine In Karachi

- Mining Quarry Stone Crushers

- Homemade Rotary

- Raipur Li Ne Crusher Leese Holder Name

- Crusher Equipment Destemmer

- Cement Mill Erection Procedure Boll Mill

- Australia Crusher In Dubai

- Exacto Vertical Turret Mill Model B