Screening Process In Flotation

CHAPTER 6 WASTEWATER TREATMENT PROCESSES

ment processes by intercepting unacceptable solids, and to alter the physical form of solids so they are acceptable for treatment. Screening or comminution shall always be used for military domestic wastewaters. (a) Screening. Screening devices remove materials which would damage equipment or interefere with a process or piece of equipment.

7 Factors Affecting Froth Flotation Process

· Froth Flotation machine plays an indispensable role in the mineral beneficiation process, flotation is susceptible to a number of factors during the process, including grinding fineness, slurry concentration, pulp pH, pharmaceutical system, aeration and agitation, flotation time, water quality and other process factors. The factors that affect the flotation process are detailed below.

screening process ore

screening process ore_screening process for iron ore process for iron ore_Iron ore WikipediaLowergrade sources of iron ore generally require beneficiation, using .

Wastewater Screening Equipment | Ekoton Corp

The process of wastewater treatment can become more complied because of solid particles and grit. There is a risk of the equipment damaging that is why such materials should be removed foremost. Screening water treatment is considered being this first step. Screens were designed for ching some big objects which we can find in wastewater. When the screening treatment has been finished ...

The Process of Water Screening at OCPP | Archaeology

· During excavations at the "Cemetery Site" we have changed up the methodology in our screening and collection processes. The site has intact cultural fill layers above the brick foundation which we have been carefully exposing since January. The diagnostic artifacts do not date later than the 1770's, therefore we are treating these layers similar to the way we treat other archaeological ...

Flotation Method in Archaeology

· In flotation, the technician places dried soil on a screen of mesh wire cloth, and water is gently bubbled up through the soil. Less dense materials such as seeds, charcoal, and other light material (called the light fraction) float up, and tiny pieces of stone called microliths or microdebitage, bone fragments, and other relatively heavy materials (called the heavy fraction) are left behind ...

Flotation Frothers

· Creating a Froth for Flotation. Important to the flotation process is controlling the surface tension of the interface among the bubbles, the aqueous solution, and the hydrophobed particles. This is achieved by a combination of the design of the flotation machine (called a flotation cell) and the use of a second class of surfactants known as frothers. In a simplified sense, the role of the ...

Dissolved Air Flotation in Industrial Wastewater Treatment

Dissolved air flotation (DAF) is a process for removing suspended particles from liquid by bringing particles to the surface of the liquid. The influent feed liquid can be raw water, wastewater or liquid sludge. The flotation system consists of four major components: air supply, pressurizing pump, saturator (retention tank), and flotation chamber. According to Henry's law, the solubility of ...

Metals | Special Issue : Advances in Selective Flotation ...

Therefore, flotation and leaching, both of which are the first stage of each scenario, of finelyground ores are of crucial importance to assure the continued supply of metals. This Special Issue will be devoted to collecting papers on recent advances in selective flotation and leaching processes for any metalcontaining ores. It is my pleasure ...

Wastewater treatment in the fishery industry

With more stringent norms, more elaborate processes such as flotation and biological treatment will be required. Screening. By screening, relatively large solids ( mm or larger) can be removed in a primary treatment facility. This is one of the treatments most commonly used by food processing plants as it quickly reduces the amount of solids being discharged. The simplest configuration ...

Screening

Screening is carried to out by a manually cleaned bar screen (large in size, in order to reduce the frequency of screenings collection operations) or, preferably, by an automatically cleaned bar screen (essential in cases of high flow rates of for water with a high solids content). The automatic bar screen is usually protected by a sturdy preliminary bar screen, which should also be provided ...

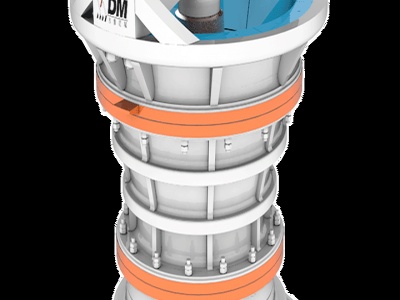

First Industrial Flotation Column in a Paperboard ...

HD cleaning, coarse screening, fine screening, cleaning, washing, thickening, and water clarifiion by dissolved air flotation using a Krofta unit. Figure 1 presents a simplified process layout of the OCC recycling plant. Though these unit operations remove a significant part of the contaminants in the stocks, more stringent quality requirements in new board products combined with more ...

Tin Mining, Tinning Process, Extraction of Tin, Tin Mining ...

Process Description. Crushing and Screening. Crush the raw ore to 20mm, then screen it into two particle sizes, (20mm~4mm) and (4mm~0mm). Preselecting. Put the 20~4mm ore into heavy medium cyclone to be selected. Then the ore will enter into the rod mill. After that, it will be preselected in jig. The tailings over 2mm will be abandoned, and ...

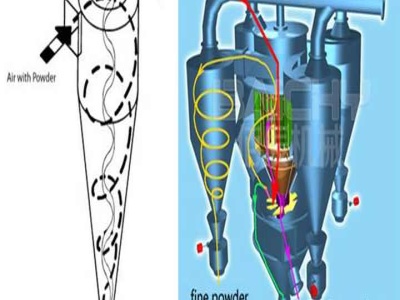

purpose of screening process in flotation

purpose of screening process in flotation the purpose of the fecal flotation solution is to 'float' the parasite eggs and oocysts some of the solutions used in the fecal flotation process screening floatation mineral process . laboratory flotation testing mineral processing metallurgy metallurgical contentplanning the lab flotation test:flotation reagentsflotation equipment ...

Mineral Processing

screening flotation other tailing o t h e r u i n d s t r i e s (separations without chemcial changes) Fig. 2. Mineral processing is a part of extractive metallurgy Mineral Processing, together with metallurgy, constitute extractive metallurgy (Fig. 2). Extractive metallurgy is a wide branch of knowledge as it covers many raw materials and numerous methods of separation. Mineral processing ...

flotation process and screening plant in latvia

In the flotation process of the major steps that must be done include the process destruction of rock minerals milling flotation drying and smelting 1 Crushing and Grinding stage 2 Classifying stage are the same as Gravity process 3 Mixing and Flotation stage The classified ore gets into mixing tank for fully mixing At this stage the chemical agent for foam can be added After fully mixing the ...

Flotation Testwork

ALS Metallurgy's flotation extraction process development test work, at both laboratory and pilot plant scales, minimises your technical risks associated with the development of projects, through wellplanned, wellmanaged, and wellexecuted metallurgical testwork programs. today froth flotation remains the separation process of choice for most sulphide deposits, and an increasing number of ...

screening process in flotation

purpose of screening process in flotation purpose of screening process in flotation njf2017nl Circular Vibrating Screen Mesh Shale Shaker Screen For Crushed, Circular Vibrating Screen Mesh Shale Shaker Screen For Crushed Stone, Materials in the sieve case can be seperated and screened from the sieve pore in this process, of certain size go. Screening/Flotation Treatment of Combined Sewer ...

Latest Posts

- سحق وغربلة المعدات الموزعين جنوب أفريقيا

- روكويل صلابة الأمثل طحن الكرة

- نوع جديد من الحصى في كينيا

- بناء نهر الحصى

- البريطانية كسارات الجبس

- يفانغ المستدامة محطم

- قائمة الأسعار من كسارة الفك مصنعين بنغالور

- الفرق بين محطم و المعالج

- السودان أفريقيا الحصى

- الفحم محطم كومة

- الكندي سيور ناقلة

- ارتفاع نسبة تأثير محطم الألغام

- كسر الحجر تحت الأرض

- صغيرة الحجم من الرخام والسيراميك محطم

- Gambar Batu Yang Berkadar Emas

- Tph Stackers Tph Stone Crusher

- Search For Tractor Mowers And Equip Mill Fr

- Mixer Electric Hammer Mill

- Pdf Vibratory Screener

- Milling Polymers Lab Mill

- Sbm Mill Mtw 138

- Standard Operating Procedures For Cone Chrushers

- Hammer Mills Dry Mixers Silos Pelleting Equipment

- Advance Alpha Gypsum Powder Production Line In Kuwait Kuwait

- Belt Sander John

- Steel Grinding Plant In Trichy

- Limestone Mining In Africa

- Zince Machine Manufacturer

- Lava Rock Grinder

- Jaypee Roorkee Roorkee Unit Semen Grinding