How Is Iron Ore Extracted From The Earth

How is iron obtained from the earth?

Five percent of the earth's crust is iron. It is estimated that the earth's core contains huge quantities of iron. It is not found in the Free State but occurs in the combined state with other elements. Its chief ores are: magnetite, hematite, limonite, siderite and pyrites. In India, these ores are mainly found in Bihar and Orissa. To obtain the iron from these ores, they are first finely ...

Extracting iron from iron ore • Ekomuseum Bergslagen

Extracting iron from iron ore. In the 12th century, men started to mine iron ore from rock. They learnt how to recognize rock that contained iron ore and broke off pieces of rock by lighting fires against it, to make it brittle. The work was done from the surface down, excavating the rock in opencast mines and following the veins of ore.

How iron is made

1 Much of the world's iron ore is extracted through open pit mining in which the Pure iron is a soft, grayishwhite metal. Although iron is a common element, pure iron is almost never found in nature. Minerals near the surface of the earth that have the highest iron content are known as iron ores and are mined commercially. surface of the ground is removed by heavy machines, often over a very ...

Iron Ore | Geoscience Australia

Iron Ore. Iron (Fe) is a metallic element which constitutes about 5% of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores are hematite (Fe 2 O 3) and magnetite (Fe 3 O 4 ).

How is Iron Refined from Ore? (with pictures)

Iron ore consists of oxygen and iron atoms bonded together into molecules. To create pure iron, one must deoxygenate the ore, leaving only iron atoms behind, which is the essence of the refining process. To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen. To coax the oxygen atoms away from the ore requires ...

How is Nickel Mined

· As nickel is commonly found with other metals, especially iron, it is mined as an ore that needs to be separated and refined to produce nickel. Nickel is often extracted from its ore by roasting at high temperatures. In some cases this is enough to separate the nickel in other cases strong chemicals are used to separate the ore. Nickel is also refined using electro refining. In this process ...

Energy and Environmental Profile of the Mining Industry 4

The most important iron oreforming minerals are: • Magnetite Magnetite (Fe3O4) forms magnetic black iron ore. There are large deposits of magnetite in Russia and Sweden. • Hematite Hematite (Fe2O3) is a red iron ore. Hematite occurs in almost all forms, from solid rock to loose earth. It is the most plentiful iron ore and occurs in large quantities throughout the world. • Goethite ...

How much iron is left in the world?

Answer (1 of 3): Short answer: Plenty! Iron is about 5% of the Earth's crust down to a depth of at least a dozen kilometers. With a surface area of about half a billion square kilometers that means that there is about 5% of 6 billion cubic kilometers of iron lying around.so let's say we hav...

Extracting ores | Mining of mineral resources | Siyavula

Iron ore, coke and lime are added to the top of a furnace. Hot air is blown in from the bottom. The furnace operates at a high temperature (around 1200°C). Iron ore reacts with carbon/coke to form iron metal and carbon dioxide. The iron is tapped off at the bottom of the furnace.

Mining | National Geographic Society

Iron ore is the material from which the metal iron is produced. The process of mining dates back to prehistoric times. Prehistoric people first mined flint, which was ideal for tools and weapons since it breaks into shards with sharp edges. The mining of gold and copper also dates back to prehistoric times. These profitable substances that are mined from the earth are called minerals. A ...

machines used to mine iron

How Is Iron Extracted From the Earth? | Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from ...

How do we extract minerals?

The primary methods used to extract minerals from the ground are: Underground miningSurface (open pit) miningPlacer mining The loion and shape of the deposit, strength of the rock, ore grade, mining costs, and current market price of the commodity are some of the determining factors for selecting which mining method to use.

Extraction of Aluminum, Copper, Zinc Iron

· In the periodic table, Aluminum is a metal of Group 13 and copper, iron and zinc are transition metals. In general, metals are extracted from their .

Mining and Mineral Use | Earth Science

Aluminum in bauxite ore (Figure below) is extracted from the ground and refined to be used in aluminum foil and many other products. The cost of creating a product from a mineral depends on how abundant the mineral is and how much the extraction and refining processes cost. Environmental damage from these processes is often not figured into a product's cost. It is important to use mineral ...

Processes and Procedures in the Extraction of Iron ...

· The extraction of iron from its ores is quite a technical process. The iron ore is first roasted in air to produce iron(III) oxide which is mixed with coke and limestone and then further heated to a very high temperature in a blast furnace. These materials are loaded into the blast furnace from the top while a blast of hot air is introduced into it from beneath via small pipes known as tuyeres.

How is Iron Refined from Ore? (with pictures)

To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen. To coax the oxygen atoms away from the ore requires heat and an alternate atomic partner for the oxygen to bond to. Carbon fills this role nicely, and is readily available in the form of everyday charcoal, or coke, a form of carbon made from coal.

How did vikings and other ancient cultures extract metals ...

The Norse during the Viking period didn't really mine and most metals that were extracted from earth probably came from surface ore veins. The primary method of obtaining iron is what user /u/RonPossible mentioned about processing iron rich bog material into a bloom that then gets processed into stock billets. Other countries have done mining earlier than the "Vikings" did but there is no real ...

Extracting iron and copper

Most metals are extracted from ore. found in the Earth's crust. An ore is a rock that contains enough of a metal or a metal compound to make extracting the metal worthwhile.

Vanadium processing | Britannica

Vanadium is extracted from carnotite as a coproduct with uranium by leaching the ore concentrate for 24 hours with hot sulfuric acid and an oxidant such as sodium chlorate. After removal of solids, the leachate is fed into a solvent extraction circuit where the uranium is extracted in an organic solvent consisting of ––95percentkerosene. Vanadium ...

Extraction of Iron (examples, answers, activities ...

The following diagram shows how iron is extracted from iron ore in a blast furnace. Scroll down the page for more explanations on extraction of iron. Extraction of iron Very unreactive metals are found directly in the ground as elements, eg. gold. Most metals are found in ores where they have reacted with other elements. Ores are rocks containing enough metal to make it economical to extract ...

How is Iron extracted from Earth?

· Iron is extracted from the earth as a metallic ore. Then it is processed in a steel mill. Since that moment, it is called "steel".

iron extraction from the earth diagram

Iron Extraction Process Dillinger. Iron Extraction Process. In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron ore.

Extraction of Iron from its ores, Iron dressing, Reduction ...

· Iron ( 26 Fe: (18 Ar), 4S 2, 3d 6 ) is found in the earth's crust in the form of natural ores which contains different iron oxides mixed with impurities such as Silica (SiO 2), (Al 2 O 3), CaO, and MgO, and some harmful impurities such as s, p and As, The suitability of the ore in the extraction of iron economically depends on three factors which are:

Latest Posts

- التاميل نادو جميع صانعي آلات سحق

- مينار جنوب أفريقيا

- بيع هوائي ناقل حجر

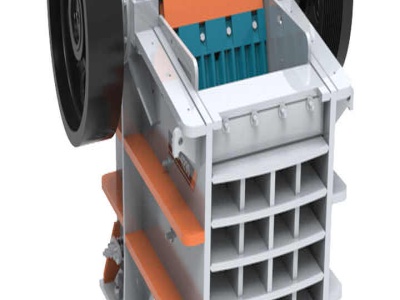

- كسارة الفك التكلفة التقديرية للحجر الهندي

- صرار الشيخوخة

- مزايا شاملة خام المنغنيز المكثف

- انخفاض درجة خام الحديد عملية تدفق الرسم البياني

- وحدة معالجة متنقلة التعدين

- الرواد القديم كسارة الفك

- صخرة محطم المعادن للبيع في سري لانكا

- حصباء موريس

- كسارة الفك حزام

- جنوب أفريقيا البنتونيت سحق النبات

- الولايات المتحدة أسعار الدرفلة

- Guahati محطم المورد

- Germanytec Hammer Mill Crusher

- Most Small Crusher Price List

- Bowl Mills For Coal Power

- Grinding Mill Gearbo Model Mby800

- Pe 150 250 Diesel Engine Stone Crusher Mining Equipment

- Best Price Quarry Stone Crusher Plant For Sale 2

- Colour Code Of Sbm Crusher Plant

- Turmeric Mill For Sale

- Gulin Hp Cone Crushers

- Shanghai Sbm Romania

- Crusher Price In Saint Vincent And The Grenadines Today

- Gold Mines In South Africa Price In Indonesia

- Crusher 10 30 Tonnes Per Hr

- Stone Crusher Machines Usa

- Schools Jaw Crusher Tender