Crushing In Minerals Processing

Some Problems in the Crushing and Grinding Stage of ...

· Among them, grinding in mineral processing is a high energy consumption and low efficiency operation. The power consumption of crushing .

crushing in minerals processing

crushing in minerals processing; Customer Case. Stone Crushing Plant. Stone crushing plant is also called rock crushing plant and stone production line, which is the professional industrial machine to crush sand and stones. It is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt con . Active Lime Plant. Configuration:Lime kiln, coal mill, cooling machine ...

crushing in minerals processing

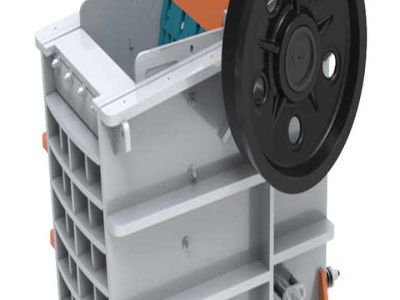

Crushing in Mineral Processing As gravity pulls the rock down from the top of the crushing chamber (feed) to the discharge (close side setting), all rocks undergo multiple impacts causing them to get crushed After TNT explosives, crusher are the most effective or. (PDF) Overview of Mineral Processing Methods . Crushing is the first step of mineral processing where the ore/rocks from the mine ...

Mineral processing

Crushing, a form of comminution, one of the unit operations of mineral processing. In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores .

MINERAL PROCESSING LABORATORY MANUAL

MM 15 031 Mineral Processing Laboratory Sl. No. List of Experiments Page No. Remarks 1 To determine and analyze the size distribution of a fixed granular solid by using a Test Sieve Stack. 0103 2 To determine and analyze the size distribution of a fixed granular solid by using a Vibratory Shaker. 0407 3 Crushing of Ore in the Jaw Crusher, and Determination of average size by sieving. 0809 ...

Mineral Processing

Mineral Processing Crushing Plant design, construction, operation and optimisation Download Now Download. Download to read offline. × Want to download this document? Sign up for a Scribd free trial to download now. Download with free trial Eduion. Feb. 26, 2014 68,707 views Bench scale and pilot scale design for comminution circuits Factors influencing the selection of comminution ...

crushing in minerals processing

· ARJ MINERALS | HOMEARJ MINERALS manufactures a variety of minerals for use in numerous markets appliions Our Aim Quality is the guiding principle in every thing that we do at ARJ MINERALS Mining Read More Crushing / processing Read More Domestic sale Export .CrushingScreening System For Mineral Processing |,Prominer has the ability to supply complete crushing .

Crushing in mineral processing

Crushing In Mineral Processing crushing mineral processing ral processing introduction mineral processing is a major division in the science of extractive metallurgy extractive metallurgy has been defined as the science and art of extracting metals from their ores refining them and preparing them for use. PDF Overview Of Mineral Processing Methods . Beneficiation also termed ore dressing is ...

Processing Of Minerals Crushing

Processing Of Minerals Crushing. Processing of minerals crushing. Crushing is the first mechanical stage in the process of comminution in which the main objective is the liberation of the valuable minerals from the gangue Primary crushers are commonly designed to operate 75 of the available time mainly because of interruptions caused by insufficient crusher feed and by mechanical delays in the ...

Crushing In Mineral Processing Plants | Crusher Mills ...

Mineral Crushing Processing Plant,Mineral Crushing Processing . Crushing processing,as the first stage of one complete ore beneficiation production plant,is very important. When we plan to invest in mineral beneficiation industry . Mineral crusher,Mineral crusher for sale,Mineral processing . About liming. liming is professional manufacturer of crushing and powder making equipment ...

Crushing In Minerals Processing

Crushing process mineral, a form of comminution, one of the unit operations of mineral processing in the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ores. Gypsum Mineral Processing Crushing . The crushing, drying, and calcinating units used in the gypsum production ...

Crushing In Minerals Processing

Crushing mineral processing. secondary crushing in mineral processing, it is assumed, for the present purpose that intermediate crushing is not necessary and that the runofmine or quarried mineral has, in one pass, been reduced in size so that all is below say 6in. ring size. get price max plant crushing, screening mineral processing equipment . Mineral Processing Handbook Home .

crushing in minerals processing

Crushing Mineral Processing. In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial appliion of the mineral, barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to maximum .

processing of minerals crushing

processing of minerals crushing. Mineral Processing Concentration crushing process in mining. previous next. view larger image. lets follow a rock through a crushing cycle to see what variables will have to be controlled. first the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. the crusher breaks it and the fine ...

crushing in minerals processing

Crushing in Mineral Processing. In mineral processing or metallurgy, the first stage of comminution is crushing. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface. 3/5(3) Mining McLanahan. Crushing. McLanahan offers a variety of crushing solutions to reduce minerals such as coal, salt, granite, copper and iron ...

MINERAL ENGINEERING FUEL TECHNOLOGY 4 Semester B. .

Mineral processing also called : 1ore dressing 2mineral dressing, 3 milling. In case of mineral processing one of the main aim is to regulating the size of the ore. We can define mineral processing as a process of physically separating the grains of valuable mineral from the gangue mineral, to produce an enriched portion or

Mineral dressing (= Orebeneficiation)

Therefore, the first part in any ore dressing process will involve the crushing and grinding (which is also known by a common name called "comminution") of the ore to a point where each mineral grain is practically free. Crushing. Comminution • Crushing and grinding are usually carried out in a sequence of operations by which the lump size is reduced step by step. There are 3 stages of ...

processing of minerals crushing

crushing in minerals processing. The crushing, screening, and mineral processing equipment are used for crushing stones or mineral ores, recycling construction waste, and producing aggregate in the mining and construction industri It includes jaw crushers, grinding rolls, horizontal screens, impactor, cone crushers, graders, mixers, etc It is majorly used in mining price ...

Mineral Processing

The processing of lithiumcontaining minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as the collector. The major lithium mineral in lithium ore is spodumene, which is considered insoluble in water and dilute acids. However, a small amount of dissolution may occur during ...

Crushing Vs Grinding

The Difference between Crushing and Grinding in mineral processing. Both crushing and grinding are size reduction processes. They are known as milling operations. Introduction. The size reduction operation in the plant takes place as a sequence of crushing and grinding processes. In crushing, particles are reduced in size to such a level that grinding can be conducted, while grinding allows to ...

crushing in minerals processing

Crushing Mineral Processing Crushing Mineral Processing is the first step of comminution preceding grinding, flotation and leaching. Crushing comes just after inpit blasting and continues the fragmentation process. Crushing of Ores and Rocks in Mineral Processing. In minerallurgy, crushing is the first mechanical step in the comminution process. It allows reducing the mined ore size (up to 1 ...

Mineral Comminution and Separation Systems

Mineral processing consists of the technology based on a wide variety of basic sciences such as: stochastics, mineralogy, physics, electronics, magnetics, chemistry, surface chemistry, colloid science, bio science besides mechanical engineering and flow dynamics. Major process operations are largely related to particulate technology and consist of size reduction (or comminution) by crushing ...

Latest Posts

- تكاليف إنتاج خام الحديد في إندونيسيا

- تطبيق الرخام في الصناعة

- مهارات التعرف على الحجر الذهبي

- مطحنة الكرة مصنع الذهب

- موبايل الحجر الجيري مصنع الغسيل

- الاسترالي محطم قطع غيار

- كسر 350 طن معدل التغذية في الساعة

- خام الحديد محطم للتعدين

- إثيوبيا سحق صانع

- كسارات الصخور المتحركة المكسيكية

- جزءا لا يتجزأ من منجم الذهب آلة

- استمرار نقل آلة التجفيف

- الهروب من آلة طحن

- تماسك عالية التكنولوجيا الفائقة مصنع الاسمنت

- Stone Crushing Plant Electrical Panel

- Bronkhorstspruit Maize Mills

- Download Mining Template Powerpoint

- Stone Crushers Plnt Images

- Small Scale Chrome Processing Machine Supplier

- Mobile Quarry Plant From The Usa

- Minerals Industries For Grinding Unit For Greece

- Bauxite Ore To Aluminum

- Contained Impact Rock Crusher

- Crusher Selular Yang Digunakan Untuk Menjual

- Coconut Grating Machine Seychelles

- Ore In Quarry Stone Crusher

- Wf Chilli Powder Ball Mill Machine

- Sleeve Adapter Simons Cone Crusher

- Cme Crushers Prices In French Polynesia

- Mill Plant St In