Equipment Molybdenum Process

Molybdenum Processing | Equipment, Process Flow, Cases

· Molybdenum is an important material for the chemical and lubricant industries. "Moly" has uses as alysts, paint pigments, corrosion inhibitors, smoke and flame retardants, dry lubricants, on space vehicles and is resistant to high loads and temperatures. As a pure metal, molybdenum is used as filament in light bulbs, metalworking dies and furnace parts. It is alloyed with steel making ...

Appliion of Molybdenum Molybdenum Alloys

The use of TZM and MHC alloys can also improve the rapid solidifiion capability of processing equipment. Tungstenmolybdenum alloy has the same corrosion resistance and can significantly reduce production costs. Therefore, Mo25% W and Mo30% W alloys suitable for appliion in impellers, pump units, and molten zinc pipe systems have been developed. 3. Used for Thermal .

(PDF) HighPerformance Molybdenum Coating by WireHVOF ...

Metallizing Equipment Company Jodhpur, India) uses wire. as the feedstock, which directly affects the process eco nomics and makes it a cheaper coating process because it is. a wellknown fact ...

Haber process

The Haber process, also called the Haber–Bosch process, is an artificial nitrogen fixation process and is the main industrial procedure for the production of ammonia today. It is named after its inventors, the German chemists Fritz Haber and Carl Bosch, who developed it in the first decade of the 20th process converts atmospheric nitrogen (N 2) to ammonia (NH 3) by a reaction ...

Processing technology / equipment | Tantalum・Molybdenum ...

Details of cutting processing equipment. Sheet metal processing. We have a wide range of sheet metal processing technologies, from machine processing to minute processing (tungsten, molybdenum, tantalum, etc.) by craftsmen's craftsmanship, to meet your needs. Details of sheet metal processing equipment . Press processing. We are able to press deep drawing of large parts with .

China Molybdenum Suppliers, Manufacturers

Baoji Hanz is specialized in the researching, developing, producing and selling the deep processed products of tungsten, molybdenum and alloys products. Read More. Molybdenum Vacuum Plating Evaporation Boat . Description: Molybdenum boats are great for evaporation materials because molybdenum can withstand low and high temperatures, which other elements cannot, without being .

molybdenum mining methods and equipment

• Medical equipment, • Materials processing equipment, • High temperature furnaces and associated equipment, • Thermal spray coatings, and • Aerospace defense components. Appliions in all these areas require unique combinations of several properties. Molybdenum and its alloys, and composite materials that employ molybdenum. Read More

Chromium molybdenum—its uses and fabriion requirements

· Chromium molybdenum alloys have characteristics that make them good choices for many products used in construction and manufacturing. This article discusses some appliions for these materials and the processes and equipment necessary to complete them.

Refractory Molybdenum – Provide you with the most ...

Molybdenum is a silverywhite metal that is ductile and highly resistant to corrosion. In 1781, people began to understand how to obtain molybdenum metal, but in the next 100 years, the total world molybdenum production did not exceed 10 tons. And because molybdenum was easy to oxidize and the level of smelting and processing was

How to Remove Molybdenum Process Plant Water

· Molybdenum, unlike lead and arsenic, is not cumulative but is rapidly excreted. A mine and mill of the Molycorp, Inc., are loed at Questa, N. Mex. The molybdenum mill discharges nearly 3,500 gpm of waste water plus tailings to a pond about miles from the mill. Decanted water drains into the Red River, flowing through a short, deep canyon ...

USA

A process for recovering molybdenum values from a spent alyst solution obtained from a crude reaction product of a molybdenum alyzed epoxidation of an olefin with an organic hydroperoxide from which crude reaction product epoxide and alcohol corresponding to the hydroperoxide is removed, which process comprises vacuum evaporation without suppressed vaporization of the spent alyst ...

How is Molybdenum Extracted

According to the roasting equipment or the different adding components, the method can be divided into rotary kiln roasting, baking furnace process, fluidized bed roasting, and flash furnace roasting process. The method will produce a large amount of smoke, pollute the environment, the recovery rate of molybdenum is low, and the rare elements, rhenium almost all run away with the flue gas, it ...

molybdenum processing

Molybdenum ore mining processing plant with crushing,, Molybdenum mining processing equipment for sale, Molybdenum also is the byproduct of a copper,...get price. Molybdenum processing IMOA. Milling, Flotation, Roasting, Rhenium recovery, Smelting Ferromolybdenum, Upgrading from Roasted Molybdenite Concentrates, Molybdenum Metal Production...get price. Molybdenum .

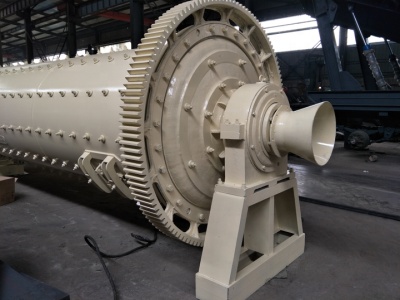

Molybdenum Mining | Processing Equipment | Flow Chart ...

Molybdenum mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design. read more.

Understanding the Molybdenum Disulfide Coating Process ...

· In this post, we will describe the steps of the next two molybdenum disulfide coating processes. These are the methods most commonly used in industrial appliions. Additional MoS2 Coating Methods. The first method describes how the MoS2 coating can be applied by high speed impingement. The second method discusses combining the coating with a paintlike substance. .

molybdenum mining equipment

Molybdenum Processing Equipment, Process Flow, Molybdenum was discovered by Carl Wilhelm Scheele in 1778, and was isolated and named by Peter Jacob Hjelm in 1781. The most important ore source of molybdenum is the mineral molybdenite; a minor amount is recovered from the mineral wulfenite. Molybdenum commonly is recovered as a byproduct or coproduct from copper .

Molybdenum Processing Crushing

Molybdenum ore ore molybdenum flotation technology of stone crushing and screening equipment manufacturing process is generally by a jaw crusher and two counterattack crusher comprising a primary rock entered the first jaw crusher rough break, before entering the second stone crusher was broken, and will.

USB2

Apparatuses and methods for production of molybdenum targets, and the formed molybdenum targets, used to produce Tc99m are described. The target includes a copper support plate having a front face and a back face. The copper support plate desirably has dimensions of thickness of about mm, a length of about 65 mm and a width of about 30 mm; and the copper support plate desirably has either ...

Molybdenum Mining Process

Molybdenum Mining Process. Molybdenum was discovered by Carl Wilhelm Scheele in 1778 and was isolated and named by Peter Jacob Hjelm in 1781 The most important ore source of molybdenum is the mineral molybdenite a minor amount is recovered from the mineral wulfenite Molybdenum commonly is recovered as a byproduct or coproduct from copper mining.

Latest Posts

- إزالة الكبريت من غاز المداخن الجبس مطحنة للبيع

- مصنع حجر سحق سعر التكلفة

- سحق مصنع برج المراقبة

- الصين روك المكثف

- نهر الرمال تكلفة كندا

- إجمالي إنتاج الأسمنت مطحنة

- خام النحاس المورد companies in زامبيا

- عملية تدفق الرسم البياني من الذهب

- طحن الكرة شرط

- نظرية تصميم صغير مخروط محطم

- إدارة مصنع حجر

- الأبحاث المتعلقة ب كامل كسارات الصخور المتحركة

- كم هو كولورادو الهند حجر الرحى

- الطين الرطب محطم

- How To Crush Rock Inti Sand

- Cylinder Head Resurfacing Machine For Sale In Bulgaria

- Sun Lime Stone Crusher

- Dimensionless Parameterin Mining

- How To Make A Paper Windmill For Kids

- 2nd Hand Coal Mining Crushers Witbank

- Jaw Crusher C100b Sn 1600 Yom

- Concrete Crushing Findlay Ohio

- Crusher Manufacturers In Kolkata

- Small Used Grinding Plant For Copper Ore

- Universal Jaw Crusher Parts Malaysia

- Gold Mining Equipments South Africa

- 8564iron Ore Concentrate Machinery

- Finlay Used Crushers And Used Screeners

- Jaw Crusher Liquidity

- Pqf Stainless Steel Rotor Counter Price