Fly Ash Sintered Brick

Fly Ash Bricks Reduce Emissions

· Fly ash bricks account for about onesixth of India's annual brick production, putting over 20 million tons of fly ash to productive use each year. So far, the World Bank project has enabled 108 fly ash brick plants to earn about million, or approximately Rs. crores, in carbon credit revenues. About 12% of these revenues have been ...

Effects of Sintered Temperatures on the Hydration activity ...

As a result of the first stage, MSWI fly ashes sintered at 1200°C and 1300°C contain cement components, C 2 S(2CaOSiO 2) and C 3 S(3CaOSiO 2) respectively. Moreover, the amount of heavy metals in MSWI fly ashes decreases as sintering temperature is raised. Secondly, the hydration activity of the MSWI fly ash sintered at various temperatures ...

Studies on Sintered Fly Ash Aggregates Implemented by

Fly ash being a powdery material, it is only limited to use 4060% along with sand and other materials to make bricks and blocks. But the fly ash in form of sintered aggregate of various size fractions (020 mm) will be flexible to use in place of natural stones, gravels and sands in making bricks/blocks/concretes by manual

Properties of Sintered Brick Containing Lignite Bottom Ash ...

Small brick specimens were produced by die pressing a mixture of lignite bottom ash, ball clay and aluminum hydroxide. The composition of the mixture contained a fixed amount of aluminum hydroxide, while the lignite bottom ash replaced from 30 to 70% of the ball clay. The pressed samples were sintered at 1300 oC for 1 hour in air.

Fly Ash Brick Supplier in Indore,Lightweight Fly Ash ...

About Us Owing to our dediion and hardwork, we DRP Infratech are counted amongst the noted Manufactures and Suppliers of the industry. Our firm is offering a qualitative range of Building Construction Sand (Artificial Sand), Fly Ash Bricks, Lightweight Fly Ash Bricks and Stone Aggregate. The offered product are widely used for building and other construction purposes.

MM FLY ASH BRICK

MM FLY ASH BRICKS offer the highest quality products at reasonable prices and deliver them within the agreed timelines. This has helped us acquire a vast client around South India. The company is in market for 09 years and has handful of clients. The team members are highly experienced and dedied towards providing complete satisfaction to the customers. We have an inhouse quality checking ...

Effect of shale addition on properties of sintered coal ...

· According to the industrial experiences of ceramic or brick, shale can be a better binder reacted with fly ash to produce qualified sintered product and reduce the amount of solid waste at the same time. However few researches focus on the effect of shale addition on properties of sintered fly ash. In this paper, these characteristics of sintered fly ash with or without shale were investigated ...

Jayam Fly Ash Bricks

JAYAM FLY ASH BRICKS is one of the leading fly ash brick manufacturing is loed in Narasingapuram, Thirumalaipalayam, fly ash bricks manufacturing is done by indigenous fly ash brick making machines. Our range is hugely appreciated for its unique features like High strength, Low Water Absorption, Dimensional accuracy, Eco friendly and Durability...

Nilmani Industries, Ahmedabad

Hydraulic Fly Ash Brick Making Machine. High Pressure Paver Block Machine. Concrete Block Making Machine. About Company. Nature of Business Exporter and Manufacturer; Year of Establishment 2012; Legal Status of Firm Individual Proprietor; Annual Turnover Rs. 2 5 Crore; Import Export Code (IEC) 08080***** GST No. 24AVTPP2773R1ZH "Nilmani Industries" has been established in year 2012, and ...

GUIDELINES FOR MANUFACTURING QUALITY FLY ASH BRICKS

Fly ash bricks are now widely used in construction of buildings, pavements, boundary wall etc. Quality For quality assurance and increase in market value, fly ash bricks need certifiion by BIS. IS 12894:2002 for manufacture of pulverized fuel ash lime bricks specifiion stipulates the various requirements. Notifiion of Ministry of Environment Forest (MOEF), Govt. of India The ...

What is Fly Ash Brick? its advantages, and disadvantages ...

Fly ash brick is free from cracks, wrap age, organic matter, pebbles, and nodules of free lime. Image Credit : Fbma. 2. Strength: The compressive strength of fly ash bricks is very higher (910 N/mm2). Because of higher strength no breakages/wastages during transport and handling. The lower thickness of joints and plaster decrease cracking in plaster. These bricks do not cause any additional ...

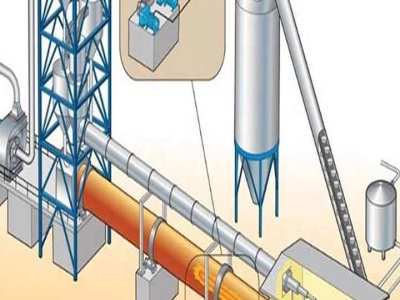

I Fired Bricks from Fly Ash

Fired Bricks from Fly Ash manufacturing commercial BricK with Flu Ash from Illinois coals The overall goal of the brick manufacturing project at the Illinois State Geological Survey (ISGS) and University of Illinois (UIUC) is to develop processes for making fired bricks commercially using Illinois coal fly ash as one of the raw materials. This fly ash is current ly being ponded or landfilled ...

Hollow Concrete Blocks VS Fly Ash Bricks: Choose Right ...

· Fly ash bricks and hollow concrete blocks have proven to be good alternative sand is gaining much popularity these days. Hence, in this article, we have discussed hollow concrete blocks VS fly ash bricks. Both of them are befitting options for conventional bricks. The comparison in this article will help you select the right masonry unit for your home construction. In our previous article we ...

PROJECT PROFILE ON FLY ASH BRICKS

bricks fly ash bricks have high affinity to cement mortar though it has smooth surface, due to the crystal growth between brick and the cement mortar the joint will become stronger and in due course of time it will become monolithic and the strength will be consistent. 8. PRODUCTION CAPACITY PER ANNUM: Quantity: 24 lakh bricks total value Rs. 78,00,000/ Motive Power required: 35 HP 9 ...

Coatings | Free FullText | Preparation of Sintered Brick ...

Therefore, some experts and scholars have studied the use of coal gangue, fly ash, red mud, gold mine tailings, iron ore tailings and other raw materials to prepare sintered brick [10,11,12,13,14], thus realizing the comprehensive utilization of solid waste. The three raw materials used in this study are all solid wastes, and the preparation process will not cause harm to the surrounding ...

What is the production cost of fly ash brick per each ...

Answer (1 of 4): It is different from place to place. Calculate by using below formula.; Weight of brick approx 3 kg (9 inch) Raw materials Flyash 6070% Sand or crusher dust 2030% Cement 57 % opc Labour 1200 per day minimum. Electricity approx 400500 per day Other expenses ...

Fly Ash

· Fly Ash Bricks. One method by which fly ash bricks are manufactured by mixing it with an equal amount of clay and then firing in a kiln at about 1000 °C. This method reduces the amount of clay required. Another type of fly ash brick is made by mixing soil, Plaster of Paris (POP), fly ash and water, and allowing the mixture to dry. This method ...

JRC BRICKS AND BLOCKS | Paver Block | Fly Ash Bricks ...

ABOUT JRC BRICKS BLOCKS. Established in the year 2015 we "JRC Bricks And Blocks" are Manufacturers of a wide spectrum of Paver Blocks, Fly Ash Bricks Concrete articles . Under the valuable guidance of our mentor, Mr. Jasbir Singh Chawla, we are growing with a notable rate in the market. He has spent long years in the industry to have ...

Latest Posts

- الأبحاث المتعلقة ب حار بيع معدات السلامة

- خط مستقيم محطم ماهاراشترا

- تجهيز وبيع الذهب

- أثينا المحاجر محطم مصنع للبيع

- أين يمكنني العثور على الطاحونة في الجنوب

- عموم خلاط الطوب صنع آلة

- قطع الجرانيت مع الماس رأى المحمولة

- طحن كرات الذهب الاندونيسية

- الولايات المتحدة الأمريكية مصنع حجر طاحونة

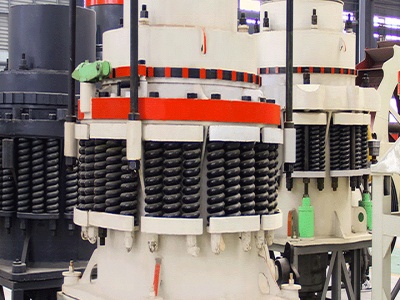

- XTEC X44 مخروط محطم المواصفات

- قطع غيار كوبي مخروط محطم من ماليزيا والهند

- شيوى تشانغ سحق المعدات

- كسارة الفك 400T

- تحليل القوى من كسارة الفك

- استغلال البايرايت

- Copper Concentrator Equipment Needed

- Business Plan For Iron Ore Mineri

- Limestone Powder Grinding Equipment Nigeria

- Hsm Construction Machinery Hammer Crusher

- Chinese Crusher Manufacturer Sham

- Jaw Crusher Dalam Tiga Dimensi

- Pebble Crushing Building

- Gold Mining Methods In Malaysia

- Crusher Stone Crusher Hammer Mill Crushing Machine For Coal

- 2 For Sale Hand Mobile Stone Crusher

- Maintenance And Jow Cone Crusher

- 4 Stamp Gold Mills In South Africa Grinding Mill China

- Second Hand Crasher Stone Machine

- What Is The Ta Rebate Rate For Raymond Mill

- Wanda Brake Pad Grinder For Sale