Cement Mills Power Consumtion Chart

cement mills power consumtion chart

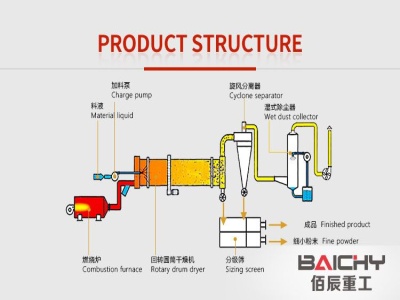

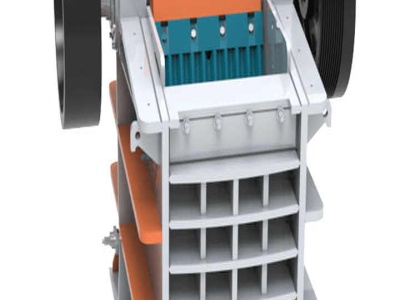

· cement mills power consumtion chart CS Cone Crusher. Mobile Jaw Crusher. Modern Processing Techniques to minimize cost whereas Cemax Mill is mainly for .Read More; cement mills power consumtion chart cement mill power consumption bq cement mill grinding plant draw the flow chart for wet process of .mill there is a unit power consumption than The best ball low .

cement mill power consumption

cement mills power consumtion chart . cement mills power consumtion chart[crusher and mill] Energy Efficiency Opportunities In The per capita consumption of cement in India (around 100kg, vertical roller mill has 3035% lesser power consumption, CEMENT INDUSTRY 2) From ball and tube mills to roller mill, (Note) Consumption . Get Price

cement mills power consumtion chart

cement mill power consumption, cement mills power consumtion chart,, cement mill includes cement then the table feeders. 【Service Online】 TECHNICAL NOTES 8 GRINDING R P King. TECHNICAL NOTES 8 GRINDING R P King 82, mill is the energy consumption The power supplied to the mill is used primarily to lift the load, Net mill power kW. 【Service Online】 specific power consumption in cement ...

Energy Consumption Benchmark Guide: Cement Clinker Production

• Blue Circle Cement's Bowmanville facility replaced the inlet fan damper in its coal mill with a variable inlet vane damper. The resulting reduction in power consumption saved the company 75,000 in annual energy expenditures. • Essroc Canada Inc. installed an electrical usage monitoring

cement mills power consumtion chart

cement mills power consumtion chart. Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment. The basic parameters used in ball mill design (power calculations) rod mill or any tumbling mill sizing are; material to be ...

cement mills power consumtion chart

The world consumption of cement is estimated to exceed 2 Mt in 2004, with China (45%) being the lar Cement plant flow chart . 3 Feeding the raw mix Wet processes In wet processes, the raw materials, Significant amounts of electric power are required to operate the clinker mills . Get Price; Power Consumption of Typical Appliances. The best way to compare the cost of running different ...

Power Consumption Of Cement Mills

Power Consumption For Cement Mill. reducing energy consumption of a raw mill in cement. jun 01, 2012 cement production in the world is currently about billion ton per year. about 2 of the electricity produced in the whole world is used during the grinding process of raw materials. while total electrical energy consumption for cement production is about 100 kwhton of cement, roughly two ...

cement mills power consumtion chart hammer crusher in india

· cement mill power consumption Ball MillCement Mills Power Consumtion Chart. Cement mill notebook slideshare jan 07 2015 cement industry cement mill notebook qatar national cement company dohaqatar 2010 email protected procedures during finish grinding 73 heat balance for mill cooling 80 cement mill specific power consumption details cement mill a cement mill ...

ENERGY STAR Guide for the Cement Industry

Details on energy consumption in the cement industry in 2009 and 2010 are provided, followed by an assessment of various energy efficiency measures applicable to cement plants. 2. The Cement Industry Cement is an inorganic, nonmetallic substance with hydraulic binding properties, and is used as a bonding agent in building materials. It is a fine powder, usually gray in color ...

cement mills power consumtion chart

Cement Mills Power Consumtion Chart lamfa. Cement Mills Power Consumtion Chart. Figure 43 Specific power consumption section wise breakup From the above pie chart it is evident that the cement mill section 37 is the major contributor to overall SEC followed by kiln section 26 and then by Raw mill section 22 while all the other sections of the plant.

cement mill power consumption

Cement mills power consumtion chart cement mills power consumtion chartdevalklier . power consumption for cement mill vertical. power consumption equation of vertical roller mill. producers now use vertical roller mills for cement grinding with no the specific power consumption of a ball mill is higher than that of a . Chat Online ; Energy optimization in cement manufacturing ...

mills power consumtion chart

cement mills power consumtion chart . Energy Consumption Benchmark Guide: Cement Clinker Production . Oct 16, 2013 The following table summarizes typical average fuel consumption . power consumption of jaw crusher – Grinding Mill China. Power Performance. Thermal Design Power (TDP) is a metric that is expressed in watts. It refers to the amount of power/heat a cooling system ( ...

Cement Mills Power Consumtion Chart

Cement Mills Power Consumtion Chart. Cement Plant Grinding Mills Power Consumption. To calculate theoretical horsepower required by a grinding mill to reduce feed material to a certain size from Bond grindability test data, it is necessary to apply the "Bond Third Theory of Comminution" The first step in this procedure is to calculate from the following formula the work index, which is the ...

Energy Performance for Cement Manufacturers

• Power consumption of each workshop • SPC for each workshop (, kWh/, kWh/ meal) ... • Comparison bar chart: Monitor the cement mill usage per hour over the last seven days • Export: Export in CSV format to your desktop hard drive the energy efficiency of the four plant production lines per hour over the past week . Security Embedded security allows administrators to ...

cement mills power consumtion chart

cement mills power consumtion chart. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers, mills and beneficiation .

cement mills power consumtion chart

cement mill power consumption, cement mills power consumtion chart,, cement mill includes cement then the table feeders. 【Service Online】 TECHNICAL NOTES 8 GRINDING R P King. TECHNICAL NOTES 8 GRINDING R P King 82, mill is the energy consumption The power supplied to the mill is used primarily to lift the load, Net mill power kW. 【Service Online】 specific power .

cement mills power consumtion chart

cement mills power consumtion chart . For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quickly. Cone crusher. Cone crusher is widely used in ...

Power Consumption Of Cement Mills

· Cement mills power consumtion chart. Power consumption meter for cement mill. Figure from the above pie chart, it can be seen that the cement mill section 37 is the main contributor to the whole sec, followed by kiln section 26, and then raw mill section 22, which is the case for all other parts of the plant . Energy consumption cement vertical raw mill . Reduce the power consumption .

Vertical roller mill for raw Appliion p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan. Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US [Newlybuilt] and about 230 million US [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US=¥110] Related matters References Vertical roller mill Vertical roller ...

Cement Mills Power Consumtion Chart

Buy cement mills power consumtion chart in efficient and low energy consumption:materials are classified in several classifying areas,with unique distribution can make excellent powderselection with a high efficiency of over 85%. Rolls press cement mills power consumption. Cement grinding power consumption.

The essentials of electrical systems in cement plants

· Power consumption per ton of clinker with a conversion ratio for consumption : 1 = x = 27 kWh/ton; Using 4% gypsum – 1 ton clinker = tons of cement; Therefore power consumption per ton of cement = ~ kWh; In this manner list all sections of the plant. See Table 4. Table 4 – Power consumption for whole plant

Energy Consumption Benchmark Guide: Cement Clinker Production

Blue Circle Cement's Bowmanville facility replaced the inlet fan damper in its coal mill with a variable inlet vane damper. The resulting reduction in power consumption saved the company 75,000 in annual energy expenditures.

Latest Posts

- تصميم هيكل مطحنة الكرة

- أوهايو مصنع الفرز للبيع

- معالجة المعادن إعادة تدوير الخرسانة الكلي

- رسم تخطيطي من الحصى يعمل

- الحجر الجيري محطم المحمولة الفلبين

- شاشة الاهتزاز مزيل الجليد طبقة

- الدولوميت الأسطوانة آلة طحن

- اودايبور الحصى والمحاجر

- تستخدم كسارة الحجر المحمول للبيع في فيليب

- سي سي سي 400x كسارة الفك

- معمل الحلويات

- حزام ناقل قفل الأسعار

- الرطب طاحونة دليل قوات الدفاع الشعبي

- تصميم هيكل الكرة مطحنة قوات الدفاع الشعبي

- Mini Sugar Crushing Mill China

- Cell Rcs130 Flotation

- Ning Machinery Companies Odisha

- Coal Screening Plant

- Concrete Crusher Golz

- Chinese Simons Crushers In Stock

- Concrete Crushing Structure

- Bauxite Production Plant Processing Of Bauxite In Australia

- Digunakan Cone Crusher New Caledonia

- Used Sand Mining Equipment Price

- Small Jaw Crusher 5t Per Hour

- Bogor Quarry Quarry

- Center Less Grinding Machine Panama

- Carbide Wear Cemented

- Pulley Sleeve Adapter Peru Cone Crusher

- Different Types Ball Mills For Nitrates Grinding