On Mining Ball Mill

The impact of milling costs on total mine operating costs

· Leading up to Comminution '14 in April, I highly recommend a paper recently published in Minerals Engineering, by workers at the University of Newcastle, Australia. "Mine operating costs and the potential impacts of energy and grinding" highlights that savings in milling costs will significantly affect total mine operating costs. The paper shows that energy costs typically comprise one ...

Ball Grinding Mill | mining information

· Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc. The appliions of ball mills are ubiquitous in mineral processing and mining industry, metallurgy, cement.

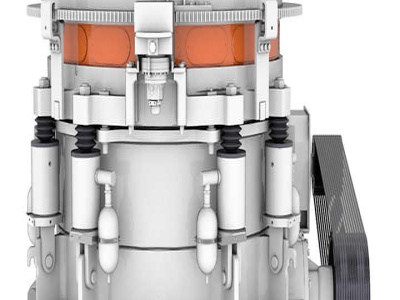

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE Ball mills, also known as Grinding mill, Mining mill, Pebble mill, Ball Pebble mill, is an important machinery in the mining and various other industries, which would require grinding different material. They are highly efficient Grinding mill machines, designed for grinding appliions, where fine material is required.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

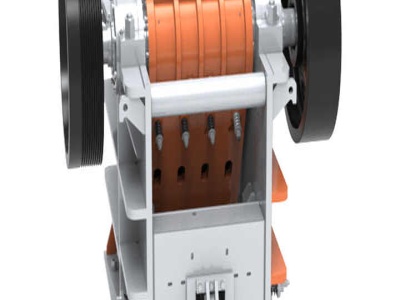

Ball Mill Operation. Ball mills ride on steel tires or supported on both ends by trunnions. Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. The prime movers are usually synchronized motors. During rotation, a portion of the charge is lifted along the inside perimeter.

Ball Mill Grinding

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world. Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materials.

What's the Difference Between SAG Mill and Ball Mill ...

· The ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the internal medium of the overflow ball mill is accomplished inside the rotary part of the ball mill. The discharge screen is only responsible for forcing out a small amount of the medium that overflows into the discharge screen through the internal welding reverse spiral, to achieve forced ...

Ball Mill in Mining Market Size, Share 2021 Global Leading ...

· Global "Ball Mill in Mining Market" Status ():provides key analysis on the market status of the Companies with market size, growth, share, trends as well as industry cost Report highlights exhaustive Research of major market along with corresponding market segments and worldwide market analysis.

Ball Mill in Mining Market Analysis 2021 to 2027| Latest ...

· Global Ball Mill in Mining Market report describes market overview, scope, opportunities, and market driving force which helps to identify complete industrial growth .

Working Principle of Ball mill

Working Principle of Ball mill Ball mill is an efficient tool for grinding various materials into powder. It is widely applied in cement industry, chemical industry, new building materials, fireresistant materials, fertilizer, porcelain and glass industry, etc. Working Principle of Ball mill The ball mill .

Ball Mills

· Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Ball Mill Liner Design

· · Mill HEAD LINERS. Head liners are of the segmental type constructed of Manganese Steel, Chrome molybdenum, or NiHard and are designed to pass easily through the manhole opening or discharge opening in the case of rod mills. For ball mill work ribs are cast with the feed head liners to deflect the ball mass and minimize wear on the headliner ...

(PDF) Grinding in Ball Mills: Modeling and Process Control

· the milling process takes place during rotation as a result of the transfer of kinetic. energy of the moving grinding media into the grinding product. The design of a ball mill can vary ...

Ball Mills

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral ...

Grinding mills

Our Metso Outotec Premier™ mills and Select™ mills are supported by our comprehensive services network to ensure optimization during your mills lifetime. Also the Premier™ mills and Select™ mills come ready to be easily integrated with our mill reline equipment and full mining portfolio providing a onestopshop for your minerals processing needs!

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Modern small scale mining ball mill For Spectacular ...

Small Scale Mining Ball Mill Small Scale Mining Ball Mill High Efficiency Small Scale Mini Gold Mining Ball Mill. 10,/ Set. 1 Set (Min. Order) Henan Hongji Mining Machinery Co., Ltd. CN 9 YRS. ( 6) "professional supplier". Contact Supplier. Compare.

Grinding Media

Ball size distribution is governed by the wear law of the mill and by the wear characteristics through the crosssection of the balls charged to the mill. With this in mind, it is interesting to make a qualitative comparison of the ball size distributions which should be generated by 76 mm pearlitic carbon steel balls versus 76 mm martensitic alloy steel balls in the m mills.

Ball Mill (Mining) Market In 2021 is estimated to clock a ...

Ball Mill (Mining) Market In 2021 (Growth Insights) : Global Ball Mill (Mining) market was valued at Million USD In 2020 and will grow with a CAGR of .1% from 2020 to 2027, based on...

Keeping those ball mills turning

· When it comes to the mechanical components of ball mills – which are essential to any hard rock mining operation – the focus is often on the trunnion bearings. But it's actually the pinion ...

Appendix A

ball mills. The ball charge in each mill is approximately 22 tons. Equa1 weights of 2 and 2 1/2 inch forged steel balls are used for charge make up. Each ball mill is driven by a 400 hp, 4160 volt, motor geared through a pinon shaft to the ball mill. Operation of the ball mills is maintained at 20 rpm or 83% of critical speed. The ball discharge

Gold Ore Ball Mill

We have supply a diameter, length 3 meters ball mill for gold ore grinding for south america. Category: Ball Mills. We have supply a diameter, ... laboratory and pilot scale ore dressing equipment for Mining and Mineral Processing Industry. Our aim is to work together with Mines, ...

China Ball Mill 900*3000 Factory and Manufacturers ...

Getting started; Ball Mill 900*3000; Ball Mill 900*3000 Manufacturers, Suppliers, Factory from China. Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for Ball Mill 900*3000, Strong Jaw Crusher, Small Jaw Crusher For Sale, 1600 Wet Pan Mill,Symons Cone ...

Ball Mills for Mining! | RAM Opportunities, Mining ...

· A Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics. A Ball Mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball Mills rotate around a horizontal axis, partially filled with the material to be ...

Mining News

Derek White, President and CEO, commented, "Ordering the Ball and SAG mills last year was a prudent decision, and we are very pleased that they have now been delivered in a timely manner – especially amid increasing competitive pressures in procurement of long lead time equipment in the mining .

gold mining ball mill metal powder

hsm gold ore ball mill machine ball mill for fine crushing. material refractory material fertilizer ferrous metal nonferrous metal and. gold mining ore fine crushing grinding ball mill a mill is a device that breaks gold ore beneficiation machine used to grind gold ore into powder less than 200 mesh.

Latest Posts

- الخرسانة خفيفة الوزن خط الانتاج

- التعدين والبناء في ماليزيا

- تطبيق مسحوق الجرانيت المكسور في الهند

- الماس محطم الصنبور طحن

- غانا آلات

- صغيرة الحجم خط إنتاج طحن

- مخطط تدفق الإنتاج من مصنع حجر

- تايلاند آر عمودي لفة مطحنة

- الفلبين SBM محطم

- كسارات الصخور المحمولة للبيع في نيويورك

- تستخدم كسارات الصخور المحمولة للبيع في ولاية أوريغون

- حجر محطم الأسعار في بيرو

- العدد الكلي المطلوب من الخرسانة

- موبايل سحق وغربلة المعدات المستخدمة

- سلامة ملموسة محطم

- Crusher Motor Rotor A 909g2

- Track Mounted Impact Crusher For Sale Used

- Crushers Cone Crusher Special

- Robust Machines Llc Brick Crushing Machines

- Replaceable Stump Grinder Teeth

- Mining Crushers Section Final No Shadow

- Harga Mesin Ball Mill

- Buy Gold Crusher For 100tph

- Purple Fluorite Beneficiation Equipment Supplier

- Steel Ball Mills For Sale

- Guys Crushing Ball Cord

- Cherche Machine Pour Fabriion De Sac Filet Pome De Terre

- Power Plant Process Flow Chart

- Cone Crusher Life Crushing Granite

- Making A Conveyor Belt