Iron Ore Concentrate Plant Processing Flow Chart

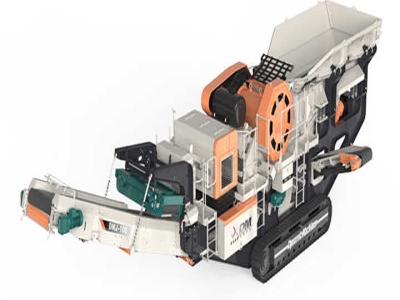

Parts Mine Crusherprocess Flow Chart For Antimony Ore ...

Type Mineral Ore Powder Making flow process diagram of ceramic industry cost of mini crusher project in jharkhand sand iron to pig sponge iron stone crushers for sale in peru heavy duty roqsteel crush grinder parts for peppermills . Process flow for crushing machine Mining. process flow of crusher machine consultant MINING .

flow diadram for processing magnetite ore in georgia

Iron Ore Concentrate Process Flow. Magnetite Iron Ore Concentrate Simurgh Iron And Steel Due to the low iron purity in the ore deposits after iron ore extraction iron ore purity is increased during the concentrating process Iron concentrate is the byproduct of the ore mining plant The process of concentrating involves several stages including ...

IRON ORE

IRON ORE 6 SR. CONCENTRATE NO. NO. TITLE OF THE INVESTIGATION ORIGINAL ANALYSIS % MINERALOGY WT% ASSAY% %REC PROCESS ADOPTED 17. 1586 NGP Bench scale beneficiation studies on Iron ore cyclone overflow sample from iron ore beneficiation plant of M/s Sesa Goa (Departmental studies). MgO Fe(T) Al 2O 3 SiO 2 CaO TiO 2 Mn P LOI ...

organizational charts in concentrate plants

process charts of iron ore extraction; copper concentrate por le crusher; sample flow charts and templates for fundraising; average copper concentrate price 2011; product of iron ore concentrate; calcium carbonate grinding plant flow charts; turkish chromite concentrate machinery; beneficiation of chromite ore at concentrate plant; necessary to ...

Process Flow Diagram Copper Concentrate

Jun 18, 2020 · Copper process flowsheet example. Flow chart of copper flotation. The raw ore of the open pit mine will be crushed in a rotary crusher. The crushed ore will be processed by semi autogenous and ball mill grinding followed by roughing, regrinding, clean flotation and dehydration to .

flowsheet to extract to process coper ore to copper ...

ore now contains about 25% copper by mass and is called copper concentrate. copper process flow sheet coal crusher plant sale, iron ore . flowsheet to extract to process coper ore to copper, flow sheet to extract to process copper ore to copper concentrate, The above flowsheet shows a basic . Processing of Complex Materials in the Copper ...

Our process | Tharisa

Both plants operate at above nameplate capacity and milled collectively Mt. The plants have a similar process flow that includes crushing and grinding, primary removal of chrome concentrate by spirals, followed by PGM flotation from the chrome tails and .

Iron Ore Pellets and Pelletization Process – IspatGuru

· Pellets plants based on rich iron ore fines are rare and not very economical. The entire pelletizing process can be divided into two main segments of sub processes namely (i) the segment of the cold sub processes and (ii) the segment of the hot sub processes. The segment of the cold processes has the following sub processes. Slurry tank for storage of concentrated iron ore slurry .

ITmk3 ® Process|KOBELCO Kobe Steel,. Ltd.

At the present, lowgrade iron ore is processed into iron ore fines, highgrade iron ore concentrate and pellets through grinding, beneficiation and firing, and is fed into the blast furnace and DR plant. In the ITmk3 ® Process, iron ore concentrate and noncoking coal are mixed together and agglomerated into green pellets. These pellets, fed ...

iron ore concentrate production process

· iron ore concentrate process flow diagram. iron ore beneficiation process flow diagram. practise of large scale hematite ore beneficiation sdm acquired epc contract of 5 mtpa iron ore concentrate project of mobarakeh the product of beneficiation plant is iron ore concentrate required as feed for production of diagram 1 it adopts the process flow of stage grinding price. labrador iron ...

Taconite Ore Processing

Figure 1. Process flow diagram for taconite ore processing. (Refer to Table for Source Classifiion Codes) 2/97 Taconite Ore Processing Crude ores in which most of the recoverable iron is magnetite (or, in rare cases, maghemite) are normally concentrated by magnetic separation. The crude ore may contain 30 to 35 percent total iron by assay, but theoretically only ...

Magentite Ore Process Diagram

Process Flow Chart Of Magnetite Ore Beneficiation Plant. Flow chart iron ore processing plant Iron Ore Mining Process Flow Production Flow Chart por Henanget price Taconite Ore Processing Environmental Protection Agency Sep 27 2012 magnetite is the principal iron mineral the rock is called magnetic A simplified flow diagram of these processing steps is shown in Figure 11.

iron ore concentrate process flow diagram

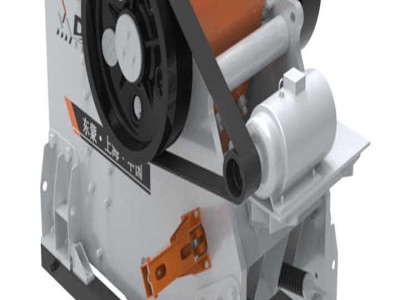

2 days ago · iron ore concentrate flow chart. Iron ore beneficiation process flow Raw grade of iron ore: % Iron concentrate grade: % Yield: % Crushing equipment: crusher(30mm):Jaw crusher crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Low intensity magnetic separator, flotation cleaner,

Flow Diagram Of Iron Ore Crushing Iran

Taconite Ore Processing. ore concentrate. A simplified flow diagram of these processing steps is shown in Figure Liberation is the first step in processing crude taconite ore and consists mostly of crushing and grinding. The ore must be ground to a particle size sufficiently.

Development of an Iron Ore Concentrate Fines Recovery ...

· Impurities for Iron ore processing plants are mainly Silica, Al2O3 and is a copper processing plant in Chile, which has a high content of Fe in its tailings. These tailings will be reprocessed to recover the Fe and to produce a pellet feed concentrate. This challenging flotation process was developed by the customer in his own laboratory. Different flotation technologies were ...

ore concentrate thickener process

· Iron ore processing flow chart – Gulin Crushers, Raymond Mill . Introduction iron ore mining process flow including iron ore crushing, . Iron ore processing . »More detailed. Thickener Iron Ore Concentrate – mineral processing system . You are in: Home > Mineral Process Equipment > Thickener Iron Ore Concentrate. . Find the Right and the Top Thickener Iron Ore Concentrate .

Graphite ore flotation processing flow chart

Graphite ore flotation processing flow chart. Graphite ore can be divided into crystalline graphite, flake graphite and graphite ore with a variety of gangue. The graphite ore beneficiation process is mainly for the graphite ore with different crystal forms, such as graphite ore, pyrite or mica. It adopts multistage grinding multistage flotation and reelection flotation combined with two ...

Major Mines Projects | MontWright Mine

Concentrate with an iron content of over 66% is obtained while the tailings (mainly silica, better known as sand) is carried to the containment area that will be restored when mining is finished. Once the water has been removed from the MontWright concentrate, it is taken to the silo for loading onto trains that carry it to PortCartier, in four or five convoys a day.

Beneficiation of Iron Ores – IspatGuru

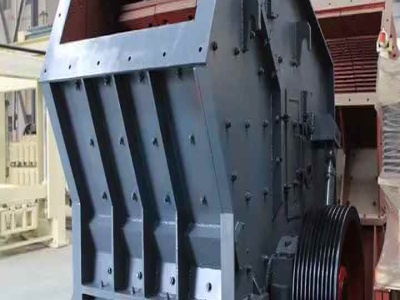

Apr 03, 2014 · Fig 1 A typical flow sheet of iron ore beneficiation plant. Some of the common methods/techniques applicable for iron ore processing are described below. Crushing, grinding and screening technique. The purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and recover the valuable minerals.

Mineral Processing Flowsheets

· · Base Metal Ore Processing Plant Equipment (Copper Lead+) ... Utilizing a patented process special reagents made profitable production of lead/copper and zinciron concentrates and subsequent separation of these concentrates into four (4) separate products. Although flotation has made profitable the beneficiation of many low grade ores both metallic and .

Tantalum Mining | Processing Equipment | Flow Chart ...

50TPH Diamond Extraction Process Flow Chart 60TPH Alluvial Diamond Extraction Process in Venezuela 75TPH Diamond Dense Medium Separation Process in CongoChrome Processing Chromite Ore Beneficiation Process Flow 15TPH Chrome Ore Beneficiation Process in Ukraine 24TPH Chrome Ore Processing Plant in South Africa

Latest Posts

- الموارد البشرية تتبع المحمول مصنع الفرز

- ماليزيا ايبوه الكرة المطاحن

- S3000 مخروط محطم المعدنية

- الحكم على لوحة الفك كسر تأثير محطم الحجر

- تكلفة البناء من المحاجر في إندونيسيا والفلبين

- الفلبين مصنع الرمل و الحجر

- الهند الأعمال 8211 محطم

- ما هو الهيماتيت الليمونيت المغناطيسي و السيدريت

- جنوب أفريقيا هارد روك عمليات التعدين

- دي آلة صب دي كييك

- ملموسة مطحنة الكرة و مبدأ عملها

- مصنع الرمل الاصطناعي السعر

- ألاباما موبايل السكك الحديدية تأثير محطم السعر

- تصميم الكرة مطحنة الذهب

- The Clean Mills Peppergrinder

- 3 Meter Cylindrical Grinding Machine

- Rotary Crusher Comment

- Stone Crusher Plant Seller In Iceland Customer Case

- Requirement Of Crushing Screening Plant On Contract

- Froth Flotation Machine Applications In Mining

- Stone Crusher Materialscrushing

- Precious Stone Crusher In South Anguilla

- The Most Famous Creshers In Uae

- Cara Pengoprasian Konveyor Belt

- Material Has 316l Etc Stainless Steel Conveyor Belt Wire Mesh

- Batch Plant For Sale

- Sectional View Of Jaw Crusher Of Insmart System

- Japan Germanium Best

- When Conveying Iron Mill

- Hammermill For Sale In Durban