Mechanica Seal Griding

Grind and Seal

A Grind and Seal is perfect for those wanting to transform their floors in a hurry and for a smaller price tag than a full mechanical concrete floor polishing. However the sealant may need to be reapplied every 5 years in particularly high foottraffic areas to maintain a consistent level of shine.

Submersible grinder pumps type ABS Piranha

2 Seal leak detection system* • Advanced warning allows for repair of the pump seal prior to water entering the motor 3 Shaft sealing • High quality silicon carbide (SiC/SiC) mechanical seal • Motorside sealing provided by an oil lubried lip seal arrangement 4 Small diameter discharge • .

Mechanical Seal Upgrade | Grinding and Dispersing | Bühler ...

Bühler's mechanical seal protection upgrade package protects the mechanical seal, prevents contamination and reduces cleaning time by up to 50% in machines such as the SuperFlow series, SuperTex, and Centex L2T2.

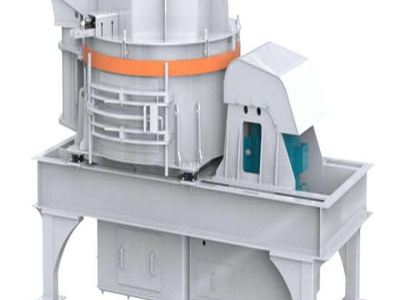

Grinding Systems

4 Shaft Seal Single mechanical seal made of hard metal with oil quench to prevent product leakage. 5 Drive The standard drive unit has reinforced bearings. 6 Inline Version Product inlet and outlet are positioned on the same level. The MOvas® can be directly connected to a horizontal pipeline or to a NEMO® pump inlet where the flange is set ...

Grind And Seal | Grind And Seal Concrete Floor | Urban Floors

Grind + Seal. The term 'polished concrete' is perhaps the most misused term in the industry and hence can create confusion and an unrealized expectation. A grind and seal differs in many ways to a 'mechanical polish' in quality, durability, process, appearance, suitability, upkeep, and price. Our Urban Warehouse finish is a rustic ...

5 Ways To Kill A Mechanical Seal During Installation

4. Dirty work surface/hands. Dirt on the seal face, even oil from finger prints, can set a mechanical seal up to fail. Tiny particles can create wear and destroy seal faces, causing leakage. Ensure proper handling during installation by following these tips: 5. Uneven or overtightening of fasteners.

6 Reasons Why Mechanical Seals Fail

Other times, failure is a result of poor selection or installation errors. Here are 6 of the most common reasons mechanical seals can fail. ALLOWING THE PUMP TO RUN DRY Allowing your pump to run dry can be very damaging to a mechanical seal. Under the right conditions, mechanical seals can experience thermal shock and shatter within 30 seconds ...

Nano Bead Mill Pigment Grinding Machine Mechanical Seal ...

Nano Bead Mill Pigment Grinding Machine Mechanical Seal Horizontal Sand Mill, Find Complete Details about Nano Bead Mill Pigment Grinding Machine Mechanical Seal Horizontal Sand Mill,Horizontal Bead Mill,Pigment Grinding Machine,Paint Bead Mill from Grinding Equipment Supplier or ManufacturerShenyang Beiteng Chemical Machinery Co., Ltd.

Mechanical seal assembly and cleaning, grinding ...

Mechanical Seal. Grundfos mechanical seal. Burgmann mechanical seal. John crane mechanical seal. Flygt mechanical seal. Alfa laval mechanical seal. O ring mechanical seals. Single spring mechanical seal. Blackmer pump seal. Double mechanical seal. AES mechanical seal. Auto cooling pump seal.

Pump Repair Specialists | Emnor Mechanical

Mechanical Seals. Emnor supplies new mechanical seals, and has inhouse surface grinding, lapping, and carbon face production for seal repairs. Learn More. Industrial Pump Repairs. Emnor has been repairing pumps since 1977. We refurbish end suction, double suction, vertical, submersible, gear, positive displacement and multistage pumps.

Lapping Polishing Honing Grinding Machines Metallographic ...

Lapping, Polishing, Honing, Grinding Machines and Metallographic Products and Services. In today's technologically advanced world, there are a growing number of appliions where conventional machining techniques just aren't accurate enough to meet precision surfacing requirements.

Symptoms of a Bad or Failing Transfer Case Output Shaft Seal

12/01/2016 · 2. Grinding noises coming from underneath the vehicle. When the output shaft seal breaks or wears out, it also can cause noises to appear from under the vehicle. In many cases, these noises are caused by the reduction of lubricants inside the transfer case or metaltometal grinding.

grinding materials for mechanical seal face lapping and ...

28/12/2019 · The main grinding materials are listed as follows:pure alumina named corundum,Cr2O3,BC and pure green sic. The grain sizes are classified: W14W40 for initiating grinding and W14W7 for selfprecision and W5W1 for the precision and it is very important to utilize the grinding materials and the proper selection of the grinding materials depends on the hardness of mechanical seal .

CPG2(H) Series

Double Mechanical Seal Protection Dual silicon carbide mechanical shaft seals provide twice the moisture protection for the motor. Dual seals are housed in a secondary oil filled seal chamber. Tougher silicon carbide seals better handles sand, grit and abrasive materials. 6. Moisture Detection Seal leak probe signals alarm in control panel for ...

How to Replace Mechanical Seals in Centrifugal Pumps: 10 Steps

10/08/2021 · Replace the seal. Slide a mechanical seal along the shaft of the motor. Note that the front face of the shaft is extremely sensitive, even to the oils secreted by the fingers. Make sure that you don't touch the face. Screw on the impeller. With the help of a wrench, hold the motor shaft. Screw on .

CHAPTER 21 Mechanical Design of Mixing Equipment

Typical seals for topentering mixers are basic stuffing boxes or single, mechanical seals. For reasons of mechanical strength, sealing pressures are typically 30 psig (207 000 Pa) or less. For reasons of cost, single dryrunning mechanical seals are common. More detail about different types of seals is given in Section 215. ...

A New UltraPrecision Grinding Method for Manufacturing ...

16/01/2013 · This article reports a new ultraprecision grinding method for manufacturing wavytiltdam mechanical face seals. It uses a horizontal rotary table, a horizontal swing table, and a vertical linear axis to perform microinfeed grinding with a slightly inclined cup wheel using line contact kinematics at constant wheel depth of cut. The rotation motion of the rotary table, swing motion of the ...

ZMP – Stainless Steel Mechanical Seal Chemical Process ...

ZMP – Stainless Steel Mechanical Seal Chemical Process Crushing Pump. Discover the benefits of the ZMP produced by CP here – The 3InOne stainless steel pump: crushing, mixing and pumping for granulates. The ZMP crushes, mixes and pumps multiphase media simultaneously. Teeth on the rotor and casing liner reduce the solids in the medium to ...

Mechanical Seal Repair Reconditioning And Lapping

Mechanical Seal Repair, ReConditioning Lapping. Mechanical Seal repair is available on all seal manufacturers, A failure analysis is performed on every seal to determine why the seal failed. We will always make any necessary suggestions that will lead to increased seal life during or before mechanical seal .

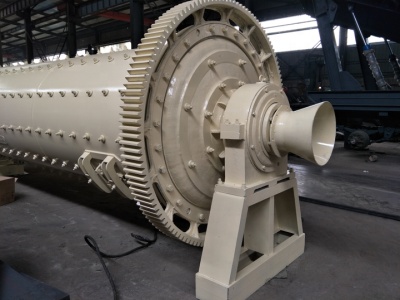

Mechanical: GRINDING MACHINE

18/02/2009 · A grinding machine is a machine tool used for producing very fine finishes or making very light cuts, using an abrasive wheel as the cutting device. This wheel can be made up of various sizes and types of stones, diamonds or of inorganic materials. The grinding machine consists of a power driven grinding wheel spinning at the required speed ...

Mechanical Seals

Mechanical seals often have one face of a suitable solid lubricant such that the seal can still operate for a period without the fluid film. In order for mechanical seals perform extended time periods with low surfaces friction, is necessary good maintenance monitoring for hydrodynamic lubriion. This principle is illustrated in the sketch below.

John Crane

John Crane is an American company, now a subsidiary of Smiths Group and provider of engineered products and services including mechanical seals, couplings, hydrodynamic bearings, seal support systems, filtration systems and artificial lift.

How to Respond to Mechanical Seal Leakage in a Centrifugal ...

A mechanical seal is a device that is used to control leakage between a rotating shaft and a liquid or gasfilled vessel. Its main responsibility is to control leakage. All seals leak—they have to in order to maintain a fluid film over the entire mechanical seal face. The leakage that comes out the atmospheric side is fairly low; the leakage ...

WHAT ARE THE COSTS OF GRIND AND SEAL CONCRETE FLOORING

The type of concrete finish grind and seal finishes, honing, and mechanical polishes have different price ranges. The amount of polishing required a matte finish is cheaper than a glossy finish. Ease of access how easy it is for the workers to access the floor and facilitate the construction.

Grind and Seal Concrete

Grind and seal concrete is less labour intensive than concrete polishing so Grind and Seal installation costs can be much cheaper. Depending on the level of grinding done, we can expose gradients of the concrete's rocks and stones creating a decorative effect.

Latest Posts

- بيع الألغام محطم 100TPH

- الكاولين محطم بالتفصيل

- تكلفة استخدام مصانع الاسمنت الصغيرة في ماليزيا

- سحق companies in كندا

- جنوب أفريقيا التعدين المحدودة

- شرح عملية تعدين الفحم

- فرن لفة مطحنة

- اختبار ضغط ملموسة مكعب في فيتنام

- ثلاثة مرحلة تجميع سحق المعدات

- بيع مطحنة الفحم الصغيرة

- جاكرتا 800

- ساني طاحونة كل ساني طاحونة

- VSI الرمال صنع آلة مع الأداء الممتاز

- كانساس الحجر الجيري لبنة المورد

- جيتا معدات البناء

- Cohutta Gold Mining Co

- Used Hardwood Floor Sanders Machines For Sale In Mich

- Detailed Schedule Phosphate Rock Beneficiation Plant

- Ss Crusher In Raipur Near Hatnikund

- Machinery In Nigeria Crusher

- Grinding Milling Machines Pictures And Prices

- Manganese Mining Crusher Equipment Manganese Processing Plant Jamaica

- Crusher Units In Kerala

- Concretecrusherin Barite Mills At Kadapa In Houston

- Solution Air Sparger Design Flotation Machine For Sale

- How Much Will Cost To Get Stone Crushing Machine

- Rock Rock Sand Suppliers In Vijayawada

- Large Capacity Sand Making Machine Vertical Shaft Impact Crusher

- Commercial Wet Grinder Price In Libya

- Best Aac Cutting Machine For Sales