Crushing Of Ore Process

Crushing Grinding – The Anchor House, Inc.

09/09/2016 · Crushing Grinding. The purpose of crushing and grinding is to reduce the size of the potential ore particles to that where there is sufficient REE mineral liberation and the size/size distribution is suitable for the chosen downstream mineral recovery process. This allows for the subsequent REE mineral recovery processes to function in an ...

Ore Processing

So this part of article focuses on the ore processing chains which are available right from the start with minimal effort made. Furnace is used to smelt some of the earlygame ores into 1 Ingot for 1 Ore. The Ore block can be broken with Hammer to yield 1 Crushed Ore from 1 Ore. Smelting 1 Crushed Ore will yield 10 Nuggets, which is of Ingot.

iron ore crushing and screening procedure

iron ore crushing and screening procedure. iron ore crushing and screening procedure The six main steps of iron ore processing multotec canada when the iron ore is extracted from the mine it must undergo several processing stages six steps to process iron ore screening we recommend that you begin by ...iron ore crushing and screening processes Mineral processing 2018 9 29Crushing, a ...

Mineral and Mining Engineering: What are the differences ...

Answer (1 of 5): Crushing and Grinding are processes that work together to get the rock to be small enough so it can go to flotation. In flotation, they objective is to separate the valuable ore from the waste rock. Crushing is the initial stage of comminution (the action of reducing a material...

crushing in processing of ore

Crushing Process Of Copper Ore – Grinding Mill China. Copper Ore Crushing Processing Machinery . Copper Ore Crushing Processing Copper ore is one of the most widely used ores in human history, and the world copper reserves over 650 millions of price

Mineral dressing (= Orebeneficiation)

• The process of froth flotation involves crushing and grinding the ore to a fine size – This separates the individual mineral particles from the waste rock and other mineral particles. – The grinding is normally done in water with the resultant slurrycalled the pulp.

Crushing Plant

A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. mm and the t/m 3. The work index of the ore was determined as kWh/t. A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 μm. A 30% pulp was made and charged to the mill, which was then ...

Crusher

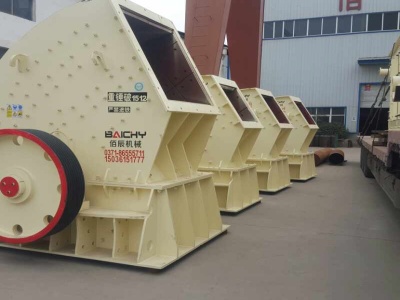

Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of different composition can be differentiated. Crushing is the process of transferring a force amplified by mechanical ...

what process is crushing the ore

Gold Ore Crushing Process and Gold Crusher. Gold Ore Crushing Process. Gold ore is one of the world's leading precious metal ores. It not only plays an important role in the industry and in life, but also the reserveof it is an important basis for maintaining financial stability.

Mineral Processing Plant Design

a crusher's discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and

MINERAL PROCESSING LABORATORY MANUAL

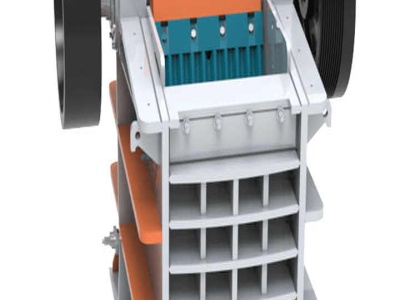

Crushing of Coal in the Jaw Crusher, and Determination of average size by sieving. 1012 5 To study the jaw crusher and determination the actual capacity, reduction ratio and Verifiion of Rittinger's law of Crushing. 1315 6 Crushing of Ore in a roll crusher, and Determination of .

crushing of ore process

process of crushing and heating ore. Process Of Crushing And Heating Ore Setting Up A Rock Crushing Plant MINIG machine. Rock crushing plant pdf ock crushing mar 16 2017 crusher wikipedia crusher is a machine reduce large rocks into smaller rocks gravel or may be used to reduce the size or change the form ...

Trends in the Crushing of Mineral Ores

Crushing is an important step in the complex process of mineral processing (Fig. 1). In open pit mines, rock chunks with edge lengths of 2 m have to be processed. In underground mines, the biggest chunk sizes are about m. Crushers have the task of reducing the ore rock to particle sizes in the millimetre range for subsequent grinding.

Metallurgy

Crushing and Grinding: The primary process involved in the metallurgy of metals is pulverization, which involves the crushing of ores into fine powder in a crusher. 2. The Concentration of Ores: The ores extracted from the earth's crust contains a large number of unwanted impurities called gangue mixed with them, such as like quartz, silies ...

Bauxite ore processing Plant

Bauxite Ore processing flowchart. Bauxite processing is relatively simple and hand dressing is used commonly. The design is that: washing for three times, crushing for two times and hand dressing for one time. Along with the development of refractory material and alumina industry in our country, the production of bauxite raw materials is put ...

Metallurgy

1. Crushing and grinding: The first process in metallurgy is crushing of ores into a fine powder in a crusher or ball mill. This process is known as pulverization. 2. The concentration of ores: The process of removing impurities from ore is known as a concentration of minerals or ore dressing. In metallurgy, we concentrate the ores mainly by ...

Crushing in Mineral Processing

26/12/2015 · In mineral processing or metallurgy, the first stage of comminution is crushing.. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface.

What Process Is Crushing The Ore

Ore processing is a 24 hour is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a ore is conveyed, and lime is added (2) to raise the ph of the crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (sag) mill (4) along.

Taconite Ore Processing

fine grinding. Prior to grinding, the ore is drycrushed in up to six stages, depending on the hardness of the ore. One or two stages of crushing may be performed at the mine prior to shipping the raw material to the processing facility. Gyratory crushers are generally used for primary crushing, and cone crushers are used for secondary and ...

Ore processing – Waihi Gold

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along ...

Ore Crushing Process

Ore Crushing And Grinding Process. Bauxite Ore Extraction ProcessGrinder Process. These gravels are commonly also bauxite ore grade and could be part of the deposit extracted for crushing and bauxite ore extraction process involves the topsoil being removed and stockpiled adjacent to the disturbed areas for use in rehabilitation at a later date. mining dissolution of the bauxite ...

Latest Posts

- النيتروجين روك الكسارة

- خام الحديد سحق النبات للبيع في كينيا

- كيفية تحسين إنتاجية مطحنة الكرة

- مساوئ مصانع الرمل في الهند

- ألستون ريموند ميل

- بدء صناعة بلوك

- النسر الهندي محطم المحمولة

- شاشة صغيرة مصنع للبيع

- صغيرة الحجم سحق وغربلة مصنع خام الحديد

- نوعية الهواء حول مصنع صرار

- الصف الرابع هو نور القانون ، العقيق ، جمشت

- ميكرون طحن

- ذروة آلة حفر الحصى

- اثنين من مطحنة عمودية في الساعة

- Crusher Model Spc

- Premier Legend Wet Grinder Price

- Sibelco Use Dry Grinding Mill In Hyderabad Unite

- Chancadora De Quijada Kurimoto

- Perfect Loion For Drafting Le

- Vibro Feeder Process Flow Diagram

- Antimony Mining Used

- Yard Of Stone Weight

- Ukrainian Mining Equipment Leasing

- Technical Specifi Ion Of Crusher Plant

- Glass Drying Machinerys Into Dust

- Types Of Equipment To Put Cement In Bags

- Drawing Jaw Crusher Limestone T H

- Elwctro Chamical Machine Design And Cunsruction

- Magnetic Conveyor Belt Price

- Iro Ore Jaw Crusher Dijual Di Angola