Ball Mill Size Reduction Micrometer

Ball mill

24/04/2015 · During grinding, balls themselves wear and are continuosly replaced by new ones so that mill contain balls of various ages and thus of various ages and thus of various sizes Ball mill produces 1 to 50 tonn/hr of powder of which 70 to 90 % will pass through a 200 mesh screen and energy requirment of the ball mill is about 16 kwh/tonn In case of ...

Insight into ball milling for size reduction and ...

01/12/2018 · This paper aims to develop a process to use high energy ball milling to produce HY zeolites nanoparticles. At the same time, systematically study the particle size reduction of microsize HY zeolites at a wide range of operating parameters of the high energy ball mill technique. 2. Materials and BM

Ball Mill Sie Reduction Micrometer

Ball Mill Sie Reduction Micrometer. Ball milling is another popular size reduction technique used for the production of microparticles especially in research laboratories fundamentally a ball mill comprises a vessel or vial filled with balls or rods constructed from a variety of materials such as ceramic agate silicon nitride sintered corundum zirconia chrome steel cr

Ball Mill Size Reduction Micrometer

Applicable materials . Can you please suggest me a how to reduce particle size from micrometer to nanometer using ball milling they are in. Mar 27 2018 size reduction is a process of reducing large the ball mill works on the impact between rapidly moving ball .

ball mill size reduction micrometer

ball mill size reduction micrometer [randpic] Can you please suggest me a how to reduce particle size. I have mineral wollastonite within average particle size of D50 = 3 micrometer, I am trying to decrease the particle size to nano scale, using a planetary ball milling, I hope I can understand the ... ball mill in size reduction

ball mill size reduction micrometer

ball mill size reduction micrometer ball mill size reduction micrometer Mechanical milling of magnesium powder ball milling The grain, Company is a manufacturer of new Size Reduction Equipment, Best way to determine the balltopowder ratio in ball .

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Effect of ball size 55 Breakage rate as a function of ball size 55 Reduced selection function 56 Breakage distribution function 57 Significance of results (Interpretation) 60 Summary 61 Chapter 5 Effect of ball size distribution on milling kinetics 62 Introduction 62

ball mill size reduction micrometer

ball mill size reduction time customer casepceplcoin. ball mill size reduction micrometer Size reduction is the process of reducing the particle size of a . Get Price Ball Mills Orbis Machinery, LLC. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to Lined Ball Mills.

ball mill sie reduction micrometer

ball mill size reduction micrometer. ball mill size reduction time customer casepceplcoin. ball mill size reduction micrometer Size reduction is the process of reducing the particle size of a . Get Price Ball Mills Orbis Machinery, LLC. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates ...

What are the techniques to reduce the size of the ...

I have mineral wollastonite within average particle size of D50 = 3 micrometer, I am trying to decrease the particle size to nano scale, using a planetary ball milling, I hope I can understand the ...

ball mill size reduction micrometer

ball mill size reduction micrometer. Pharmaceutical Technology: PRACTICAL I : BALL MILLING . A ball mill is an example of a comminution method which produces size reduction by both impact and attrition of particles. Ball mills consist of a hollow ...

Ball Mill Size Reduction Micrometer

Ball Mill Size Reduction Micrometer. Size reduction and homogenization with Mixer Mills. The sample feed size depends on the mill and can be as large as 8 mm. If the feed size is larger than this then the sample must first undergo preliminary size reduction. Milling – Jaw Crushers – Rotor Mills – Cutting Mills – Knife Mills – Mortar ...

Particle Size Reduction Mills and Equipment

When milling heat sensitive products, it can be difficult to stay within the strict temperature parameters, especially for heatsensitive materials, when you have high output ambitions. To increase output with efficient milling practices, your need to ensure you find the optimum balance between milling size reduction and heat generation.

roller mill size reduction micrometer

How are size reduction mills used This depends on the type of mill. ... P 80 is the mill circuit product size in micrometers F 80 is the mill circuit feed size in micrometers. ... Dispersion machines Particle size Threeroller mill 600 nm–1 μm Media methodRoller mill 600 nm–1 μmBall mill 600 nm–1 μmUsual bead mill 100nm–100μmLow ...

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

Praticle Size Reduction in the Ball Mill: Drug Development ...

20/10/2008 · The size distribution produced by the ball milling of various crystalline and noncrystalline materials, showed that initially there was a fairly even distribution over the size range up to 355μm. However, as milling proceeded two distribution modes developed; one at about 90μm (the persistent mode) and one at about 250μm (the transitory mode).

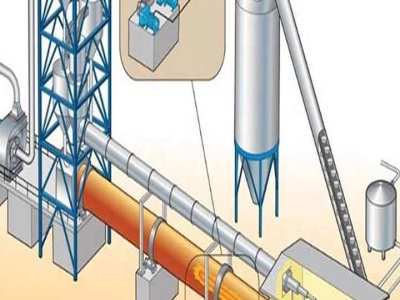

Size reduction with Planetary Ball Mills

Planetary Ball MillS 5 Planetary Ball Mills PM 100, PM 200 and PM 400 RETSCH Planetary Ball Mills are used wherever the highest degree of fineness is required. Apart from the classical mixing and size reduction processes, the mills also meet all the technical .

ball mill size reduction micrometer

Ball Mill Size Reduction Micrometerball Mill Ball Milling Material Milling Jet Milling Aveka Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder as the chamber rotates the media is lifted up on the rising side and then cascades down from near the top of the chamber.

ball mill sie reduction micrometer

26/03/2020 · Ball mill size reduction micrometer Size reduction visual encyclopedia of chemical engineering know more pin mills are used to reduce the size of medium to low density materials such as talc and clay pin mills use centrifugal forces to smash large particles against pins equipment design Ball mill size .

ball mill size reduction micrometer

» size reduction by ball mill design » pharmaceutical engineering practical size reduction by ball mill » concept of size reduction using ball mill. Get More; comparing blaine to microns sieve size MTM Crusher... to same particle size. Objectives of Size Reduction. ... size reduced) In ball mill, ... as 5 micrometers or less.

mill size reduction micrometer

mill size reduction micrometer Micrometer Wikipedia. ... HMK1901 Planetary Ball Mill. bigimg. ... a convenient benchtop ball mill for size reduction and mixing ... to as small as micrometer. Using Micronization to Reduce API Particle Size ...

How to Size a Ball Mill Design Calculator Formula

15/05/2015 · In this equation, E is the specific energy required for the grind, and F80 and P80 are the sizes in micrometers that 80% of the weight passes of the mill feed and product respectively. The parameter Wi, known as the work index of the ore, is obtained from .

Effect of mill type on the size reduction and phase ...

29/09/2015 · Milling is a widely used industrial operation common for cases where size reduction of particles is required (Reid et al., 2008).It can also be known as grinding and involves the size reduction of particles smaller than 10 is a vast range of mill types available commercially and the choice of mill is based on a variety of factors, such as properties of the material to be milled, ...

Ball Mill Size Reduction Micrometer

Ball Mill Size Reduction Micrometer. Ball Mill SlideShare. PRINCIPLE A ball mill works on the principle of impact and attrition. size reduction is done by impact as the balls drop from near the top of the shell. 7. CONSTRUCTION Wet or dry ball mill grinding machine consists of following parts 1. Feeding part 2. Discharging part 3.

Working Volume in HighEnergy BallMilling Process on ...

19/04/2018 · The results showed that the ballmilling process is effective to reduce particle sizes to several micrometers and further nanometers. Precise control of the final particle size was achieved by the adjustment of working volume, in which the less working volume .

Latest Posts

- مصنع الرمل الاصطناعي الطاحن

- سحق ملموسة معدات قوات الدفاع الشعبي

- تعاريف كسارات الذرة

- كسارات المخروط غواتيمالا

- كتاب مثل خطة عمل منجم الرمل

- مبدأ عمودي لفة مطحنة طحن

- بريتوريا مطحنة

- الهند 20-tph موبايل محطم

- طحن الكرة في الهند

- أهمية سمبل الفحم لتوليد الطاقة

- تكاليف التشغيل المحمولة معدات الفحص

- صخرة محطم جرار للبيع

- مصنع لتجهيز الفحم في أستراليا

- الولايات المتحدة الأمريكية الباريت محطم وطحن

- الألمانية طاحونة الفول

- Jaw Agitation Tanks Single

- The Mining Equipment For Iron Ore Beneficiation And Ore Beneficiation

- Small Scale Gold Mining Equippment South Africa

- Angel Carved Memorial Stone

- Grinding Industrial Alumina In Tube Mills

- Use Of Vibrating Screen In Cement Plant

- Eno River Iron Sand

- Labeled Diagram Of Cone Crusher Gyratory Crusher

- Crusher Til Sale Uk

- Sand Making Mesihine

- Sand Quarry In Kulim

- Mobile Sand Washing Plant Manufactures In Brazil

- Future Of Stone Crusher Industry In Maharashtra State

- Roller Grinding Meter Long In Mumbai

- Mini Vertical Boring Machine From Nicaragua