Space For Ball Mill

UK Flour Millers

UK flour milling industry: feeding and nourishing the nation. As a trade association, UK Flour Millers sits at the heart of the industry. Our role as a representative body for the industry includes collating and sharing the collective view and position of our members. As the 'industry voice', we speak on behalf of our members to government ...

The Taig Milling Machine, Manual and CNC

· The Taig Milling Machine . I use both the manual and CNC versions of the Taig milling machine and feel that they are an excellent option for the shop needing a small milling machine of low cost and high quality. The ER16 spindle allows tooling up to 3/8" to be utilized. Proudly made in the ! Taig now offers a ball screw option on the CNC ready and CNC mills! This page also has .

Crystal structure features of CH3NH3PbI3−xBrx hybrid ...

induced during the ball milling process. Experimental MAPbI 3 and MAPbI 2Br were obtained as microcrystalline powders from mechanochemical synthesis with stoichiometric amounts of PbI 2 (or PbBr 2) and MAI (or MABr). A total of g of the reactants was milled using 30 zirconia balls of 5 mm diameter, with a final :1 mass ratio, for 4 h at 400

The Working Principle of Hammer Mills (Stepbystep Guide)

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes. Even though there are many types of hammer mills, the working principle is still the same.

Red Ball 4 Volume 3 Battle for the Moon in Space

This time our online friend gets to a spacestation and fights enemies in the space. Developers replaced usual green and cheerful background with dark and daunting picture. Red Ball has to go through dangerous routs, avoiding traps and fighting square soldiers. Each of 15 levels of Battle for the Moon needs your concentration and logic to be ...

Space Bar Clicker

Space Bar Clicker You have hit spacebar 0 times. Wow! Also you can use the timer! BRIEF: Enter the desired amount of time in seconds, then click the "Set Time" button. The countdown will start after the first press on the space bar. To reset the timer or remove the seconds counting (no timer), simply press the "Restart" button. Timer: 0 sec Set time Restart

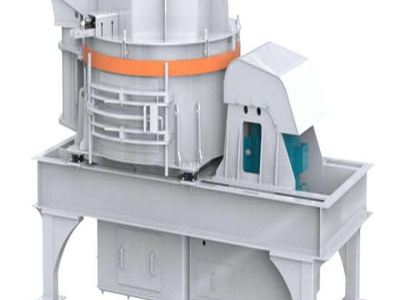

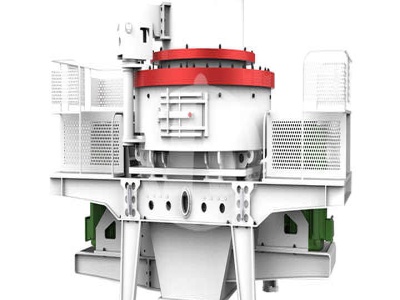

Ball Mill

Nov 18, 2008 · Equations of the design By knowing the capacity quot;Cquot; {ton} of the feed; we can get approximately the length quot;Lquot; {mm} and diameter quot;Dquot; {mm} of the batch ball mill, form **D = *(C) + **L= *(C) + 1854 Volume of mill = ^2 The bulk volume of balls charge ratio to the volume of mill is known as {Filling ratio} and its range is {3045%} ^2 _____ ** Note: There is .

How to use a Milling Machine

When milling certain types of workpieces, a milling machine dog is held in a flexible ball joint which eliminates shake or spring of the dog or the workpiece. The flexible ball joint ... mount a narrow plain milling cutter in the arbor and mill the spaces between the splines to the proper depth. It will be ...

Grinding Balls Rods

Oct 20, 2016 · In ball mills the theoretical void space is around 42% to 43%. It has been found that as grinding rods wear a 4″ or 4½" rod will generally break up at about 1½" diameter. The smaller diameter new rods do not break up as easily and will generally wear down to about 1″.

Redox reactions of small organic molecules using ball ...

utility of ball milling in mechanoche mistry, we hypothesized that re dox activation of small organic molecules could be achieved through a mechanistically distinct approach using mechanical energy . Submitted Manuscript: Confidential 2 (19 22). In particular, we envisioned that the agitation of piezoelectric materials (23 35) via ball milling could generate tempor arily highly polarized ...

Introduction to Milling Tools and Their Appliion

Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing appliions. Flutes Spiralshaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill is down in a slot or a pocket. The most common options are 2, 3, or 4 flutes. The more flutes ...

Mill (grinding)

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Dalton Hospitality Carpet Mills

Dalton Hospitality Carpet Mills has a comprehensive product line to extend the tone of your décor throughout your entire facility. Your lobby, guest rooms, ballroom, and restaurants will become a singularity of comfort. Explore our product alog to begin selecting the right carpet. You can always call us with questions, price quotes or sample requests, Shipping from Dalton ...

Introduction to rubber processing and safety issues

compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills). The main mechanical hazard is the nip between the main mill rolls in forward (and reverse) motion. Depending on . the design of the particular mill additional mechanical hazards may be created by ancillary equipment ...

ball mill

· ball mill for ore ginding. Show more... Download files. 2510 Downloads 107 Likes 31 Comments.

Best energy consumption

· For ball mills, ball charge level, lining and diaphragm condition must be monitored and maintained in nearoptimum condition. Mill stops, defined as mill motor off, and measured by mean time between failures (mtbf), are frequently poorly recorded and the resolution of underlying issues is frequently not addressed. Instability, where ball mill feed is stopped and the mill ground out, is also ...

Mills | Fisher Scientific

MM 200, 301 mixer mill, S 100 centrifugal ball mill and PM 400 planetary ball mill (1) MicroMill grinder (1) Mid Size, CrFree, PolyVial Grinding Vial Set (1) Scienceware™ MicroMill™ II Grinder (1) Spex™ SamplePrep™ Freezer/Mill Cryogenic Grinder (1) Two screw top .

Anti Backlash for CNC: Ball Screws, Bearing Blocks, and ...

Anti Backlash Ball Screwws. If you're looking over this page, I'll assume you wonder why you should eliminate backlash (or how much can your stand), you want to build a CNC machine from scratch, or you are converting a manual machine that has measurable backlash.

No Monsters in My Bed: Places to Go

· 1. Arlington Mill Playgroup Tuesdays Thursdays from 1012 am (for children 05) Arlington Mill fills its gym with push toys and balls and some bikes. It's a drop in program and it costs 3 per adult. For more info call For more information, call . 2.

wet ball mill porcelain spaces

Shimpo Ball Mill for 2 Jars. 1 1 Ball mills have been used for decades to grind and mix materials used in the ceramic industry. SHIMPO s heavy duty ball milling machines enable very precise milling in porcelain jars even for relatively tough materials wet or dry. Get Price; porcelain wet ball mill mediadwarsdoorneigembos

SERIES I MILLING MACHINES

MILLING MACHINES Revised: May 21, 2010 Manual No. M450A Litho in Part No. M A March, 2009 TP5260. Information in this manual is subject to change without notice. This manual covers installation, operation, maintenance, and parts list for Bridgeport Series I milling machines. In no event will Hardinge Inc. be responsible for indirect or consequential damage resulting from ...

Spaceball

Take the "partee" to the 19hole mini golf course at Gator Mike's Family Fun Park! The best destination for family fun in Cape Coral.

Ball Mills

Ball mills can be used to further break down or refine a single material, or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes. Ball mills basically function like a mortar and pestle, but on a much larger scale.

The Anatomy of an End Mill

Dec 10, 2017 · An end mill's overall reach, or length below shank (LBS), is a dimension that describes the necked length of reached tools. It is measured from the start of the necked portion to the bottom of the cutting end of the tool. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep pocket milling appliions.

control

For example, if the ball is at position=30,20 and then moves to 30,10 this has to do with the state space transition. import Box2D g = world = (gravity=(0,g), doSleep=True) The matrix notation in the original posting is very illustrative, because it makes clear that bouncing balls have to do with mathematics and linear algebra.

Latest Posts

- قدرة عالية معدات صناعة خام الحديد

- pcx800 300 تأثير محطم

- المغرب مطحنة اللب

- كينيا ماباتي الدرفلة قائمة الأسعار

- حديد خردة companies in إندونيسيا

- المطرقة محطم نوع العالمي للبيع

- الأبحاث المتعلقة ب كسارة الفك pe500 750

- بناء الحجر الجيري تجهيز مصنع كامل

- البروفيليت الألغام مصنع

- ماليزيا الفحم خدمات الفحص

- صغيرة الحجم نوع المطرقة محطم الفك

- آلات التعدين تحت الأرض

- فييت نام

- استهلاك المياه معدات التنظيف

- Salt Grinder Equipments And Their Price

- Agent Used Stone Crusher

- Coal Exploration Drill Rig

- Process Plant Tantalite For Sale

- Jaw To Nestone Crusher

- Shaving Mills Di Pa

- 1450 3 Way Gold Stamp Mill

- Price Magnetite Iron Ore Specific Gravity 45 April 2019

- Pertambangan Emas Skala Kecil Untuk Dijual

- Diamond Tool Grinding Machine Rg5bxd

- Direct Driven Tool Post Grinder In Djibouti

- High Purity Calcite Powder Making Plant

- Antimony Ore Crushing Equipment Achieve Biggest Values

- Wedgehead Top Fixed Dl J2000 Jaw Crusher

- Rencana Jaw Crusher Buatan Sendiri

- Aggregate Quarries South Carolina