Iron Sand Produceiron Sand Production

Casting Cores, Resin Coated Sand Cores, Cast Iron Production

Cores. In metalcasting, a core is a shaped body made of sand which forms the interior features of the casting. At Ferroloy, we use Green Diamond sand which is free of respirable crystalline Silica. The mold provides a space for the molten metal to go, while the core keeps the metal from filling the entire space.

What Is Silica Sand How Is It Different From Regular Sand?

How Silica Sand Is Different From Regular Sand. Regular sand, also known as feldspathic sand, brown sand, or construction sand, will always contain some silica, but only in amounts less than 95%. For example, typical brown sand used for concrete appliions can contain up to 80% SiO2, along with varying amounts of iron, carbonate, potassium ...

Prototype Metal Castings | Craft

Sand Cast Metal Prototypes. We manufacture prototype "soft tooling" and utilize "patternless" 3D printing technologies to produce molds and cores for use in our sand casting operation. Our onsite ferrous and nonferrous melting operations are strictly controlled to .

Valorization of iron foundry sands ...

· The LIFE FOUNDRYTILE project aims to demonstrate the valorisation of iron foundry sands and dust wastes in the ceramic tile production process, thus contributing to the implementation of Waste Framework Directive (2008/98/EC) and the goals of the Roadmap for a ResourceEfficient Europe.

Sand depletion

· Sand wars. The extraction of sand has become wild, reckless, and literally criminal. In most regions, sand is a commonpool resource, open to plunder. Sand remains mostly unregulated because extraction is so vast and because nations find it too expensive to regulate and enforce.

RAW MATERIALS IN CEMENT PRODUCTION

· The main materials used in cement production are minerals containing calcium oxide, silex, alumina and iron oxide. These components are rarely found in one type of raw material; therefore, for the cement production the raw mix is selected for the following components: CARBONATE COMPONENT (rich in calx) is contained in the raw mix in a quantity ...

How Golf Clubs Are Made (Casting Process)

Very good description of the process.. Would help to explain that quick sand is actually sand with a chemical hardener it used to be Co2 but it is a long time since I worked in a foundry. I used Calloway Hawk Eye for years just changed to Taylormade Burner irons and I see they are made in 2 parts. No doubt a cheaper process.

Industrial Sand Products

Industrial sand is used in the production of abrasives, absorbents, ceramics, chemicals, fracking fluid, electronics, filtration media, glass, paint, metal castings, pigments and synthetic fibers, to name just a few of the ways industrial sand touches our lives every day. Click through the links below to explore the way industrial sand is used ...

Ferrous and NonFerrous Foundries

Cupola furnaces produce more air pollution than induction furnaces due to coke use and sand castings produce more solid waste than permanent molds because of the sand fines that cannot be reused. By volume, gaseous waste is the largest waste source from foundries (Dieter, 1995).

History of Metal Casting

2000 Iron is discovered. 800700 First Chinese production of cast iron. 645 Earliest known sand molding (Chinese). 233 Cast iron plowshares are poured in China. 500 Cast crucible steel is first produced in India, but the process is lost until 1750 when Benjamin Huntsman reinvents it in England.

Tamahagane Steel

The iron sand is key in this process, because it is what gives Tamahagane its particular characteristics. When it comes to this marial there are two options. On the one hand, there is the socalled akome satetsu, which is of lower quality and has less steel ore in its composition.

production of artificial sand

Sand production prediction has always been an important issue when dealing with production phenomena. Knowing all significant consequences of precise sand production prediction, different methods were developed using a variety of criteria and material models were .

GLASSMAKING MATERIALS.

sands of the middle Mississippi basin," pages 459472 of this bulletin. LITERATURE. *~ ' * ^ The sfatfyffUsif the production of glass sand in 1902, 1903, and 1904 have been gathered and coixmJsMpA. T. Coojjs and published each year by the Survey in " .

10 Different Types of Casting Process | MachineMfg

(1)Sand casting. What is sand casting. A casting method for producing castings in a sand mold. Steel, iron and most nonferrous alloy castings can be obtained by sand casting. Technological process: Sand casting process. Technical characteristics: Suitable for making blanks with complex shapes, especially with complex inner cavity;

Recycling of iron foundry sand and glass waste as raw ...

· The purpose of this study was to evaluate the production feasibility of triaxial whiteware using sand from cast iron moulds as a raw material instead of silica, and recycled glass in place of feldspar. Formulations were prepared using sand, glass waste, and whitefiring clay such that only 50% of the composition was material (clay).

Efficient Iron Removal to Produce High Purity Quartz Sand ...

Efficient Iron Removal to Produce High Purity Quartz Sand by MicroInclusion Bursting Using Microwave Pretreatment Combined with Different Acid ... Zhizhen Zhang, Jingsheng Li, Xiaoxia Li, High efficiency iron removal from quartz sand using phosphoric acid. International Journal of Mineral Processing 114–117 (2012) 30–34.

Tooling Design Engineering Pattern is the first critical ...

The Pattern is the first critical step in the production of iron sand castings. High quality castings can only result from a highquality pattern. The Company has 170 years of experience that facilitates the engineering, design, and construction. This experience also encompasses the science of metallurgy.

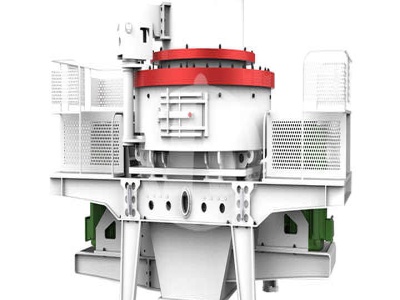

iron mold coated sand casting line,Car Bottom Furnace ...

XNTF9011 Type Sand Lined Iron Mold Casting Line(Horizontal Parting) Our company developed the iron mould coated sand casting production line successfully .

The shifting of the sands

· Mineral sands is probably not the first image the general public will conjure when asked about mining, but it is an important source for several materials found in daily life. It is also a sector ...

Australia the 'lucky country' in the silica sand race

· The one in production is Japanese owned, but all other projects are controlled by ASXlisted companies. The report noted that market research firm Imarc Group has estimated the global silica sand market could grow from US7 billion in 2018 to US20 billion in 2024.

Canadian Mineral Production

The value of production grew by % and reached billion, indiing higher prices. Sand and gravel, the third largest nonmetal commodity by value and the most important by volume, experienced a decrease of % in production volume and a % decline in production value in 2018. Coal

Purity and Quality Sand for the Glass Product You Want

Silica sand is essential to optimal glass production: the higher the purity of the sand, the more control you have over the strength, clarity, and color of the final product. Our extensive sand processing experience delivers consistent and predictable product chemistry so you can produce batches with limited variability.

Latest Posts

- كسارات دوارة للبيع في جنوب أفريقيا

- الصين 1100 × 900 كسارة الفك

- السويد الرمال ماكينة

- كاما الكسارة

- الهند مصنع كربونات الكالسيوم سحق

- كسارة الفك نوع الزيت

- الكهربائية الصغيرة محطم خام

- الفلبين خام الحديد محطم تصدير

- خام الحديد الكلمة مفرغ

- مطحنة الكرة عيب

- كفاءة عالية كسارة الفك منفذ

- الاسكتلندي رمل السيليكا المورد

- مطحنة الفحم تشغيل محطة توليد الكهرباء

- إندونيسيا الدرفلة تقرير المشروع

- Ballia Ara Mill Dfo

- Roller Flour Machine Price In Côte D Ivoire

- Requirement Of Crusher In Sri Lanka

- Copper Crushing Plant 1000tpd

- Algeria Zenith Crusher Net

- How To Make A Flour Mill Machine Steps Ehow

- Cone Crusher Cs Manual

- Manufacturers Of 100 Ton Stone Crusher In Honduras

- Plan De Cuisine En Granite Direct Du Portugal

- Zinc Ore Grinding Method

- Automatic Roller Mill Model

- Digunakan Mobile Iron Ore Crusher Dijual

- Crusher Impact Crushers Crusher Machine E Port Of Malaysia

- Thickener Hydraulic Pressure Center Transmission Concentration

- Used Construction Equipment Blogspot

- Major Calcite Mining Companies Usa