Starting Coal Grinding Mill

Coal Crushers | Coal Pulverizers Mills | Williams Crusher

Pulverizers Coal Grinding Roller Mills William's Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

Ball Mill Design/Power Calculation

Jun 19, 2015 · Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps ...

how to coal mill

how the efficiency of coal mill can maximized Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in .

Exploring ball size distribution in coal grinding mills ...

May 01, 2014 · The samples were ground for, 1 and min in a mill with m diameter and m length (see Table 3), to measure grinding rates and also estimate the breakage function. The mill speed was 75% of the critical speed and mill filling was at 40% ( kg of steel balls).

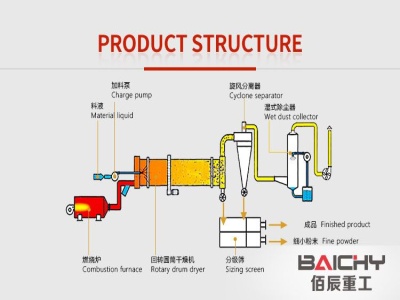

China Air Swept Coal Mill

Coal mill is the main equipment of cement plant and is used for drying and grinding coal pulverized. It is made up of the feed device, main bearing, rotary part, driving device, discharge device, high pressure starting device and lubriing system. The coal mill features rational structure and high grinding .

Coal Mill – Coal Mill In Cement Plant | AGICO Cement Equipment

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination. However, due to the flammable and explosive characteristics of pulverized ...

Grinding Mill Power

May 08, 2017 · A lifter mill of 6 ft diameter, revolving at , is grinding coal. The body of the mill is divided into two sections: one section, ft long, being charged with 5 tons of steel balls, of 2 in. average diameter, and the other section, 15 ft. long, being charged with 6 tons of "Cylpebs" of 5/8 in. average diameter.

Mill Inerting Systems Presentation to the ASBCUG

Jun 07, 2018 · Mill Inerting Systems Presentation to the ASBCUG. Richard P. Stormrichardstorm (205) . Maximum capacity, reliability and performance of your operation rely on the critical roles that your coal mills perform: Conditioning coal for proper combustion. (Fineness, fuel distribution, throughput)

Ball Mill for Coal Grinding

Meter. We are one of the wellknown manufacturers, exporters and suppliers of Ball Mill for Coal Grinding. The offered Ball Mill is very widely used for the grinding of iron ore. Our supplied Ball Mill is highly acclaimed and appreciated by the clients, owing to the hard wearing design and sturdy construct. Features: Quick grinding mechanism.

How To Start A Chilly Grinding Mill

Sep 14, 2020 You only need 2 things to start grinding flour today A mill; Some wheat (whole berry) GET A MILL. The home grain mill is the appliance that will obliviate tiny hard wheat berries (also called kernels or grain) into fluffy warm flour. You can use a hand crank model that uses elbow grease or you can get an electric one

(PDF) Control for pulverized fuel coal mill

The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the eduional simulator. The coal mass flow and the outlet temperature are modeled by ...

Pulverizers 101: Part I

Aug 01, 2011 · A fire beneath the grinding zone provides the ignition temperature to initiate a mill "puff" when restarting a mill after a trip or restarting it after a main fuel trip when coal remains in the bed.

Differences in dry and wet grinding with a high solid ...

Nov 01, 2019 · Variation in acceleration factor, κ, with fineness of grinding for − + mm coal batch ground in water (70 vol.% solid concentration) and air (fill rate of mill volume, J = %, powder–ball loading ratio, U =, 35 mm balls, and powder filling fraction, fc = %).

Mill (grinding)

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals (, via a hand crank), working animal (, horse mill), wind or water ().

MPS vertical roller mill for coal grinding

The coal mill of the type MPS 3350 BK with an installed gearbox power of 1050 kW is designed to grind 80 t/h of coal to a product fineness of 12 % residue on 90 microns and 60 t/h of pet coke to a product fineness of 6 % residue on 90 Pfeifer's skilled .

Modeling and outlet temperature control of coal mill using ...

Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding with its finer grinding requirements coming more ...

Coal grinding technology: a manual for process engineers ...

The wet ball mill grinding system was operated in open circuit, first grinding coal in No. 6 fuel oil and then grinding coal in water. The air swept ball mill grinding system was returned to service after acceptable specific energy more » values were demonstrated.

Coal Mill | Coal Grinding Mill Producer | SINOMALY

SINOMALY coal grinding mills are used in coal powder production lines with an output range of 883t/d. We have decades of experience in the production of coal mills that are designed to handle a wide variety of bituminous coal and anthracite with a maximum capacity of 85 T/h.

Coal Grinding Mill Plant Manufacturers

Feb 24, 2020 · Coal Grinding Mill Plant Manufacturers Analysis Of Coal Gangue Raw Materials. Coal gangue is a kind of unavoidable solid waste in the process of coal mining and coal washing. In terms of composition, it is a kind of black gray rock with low carbon content and harder than coal associated with coal seam in the process of coal formation.

costs for coal crushing and grinding

cost to start coal open pit mine grinding mill china. principle of coal crusher. RCW De Witte crushing, screening and grinding of iron ore. Through 30 years of development, SKY has expanded its businesses into the fields of building aggregates, ore processing, industrial grinding and green building materials.

Ball Mill

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding appliions. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

Latest Posts

- أسعار مصانع التعدين الألمانية

- الملح الصناعي مطحنة محطم

- مخروط محطم من المكثف

- نيوزيلندا الصينية كسارة الفك

- صخرة سحق المعدات

- للبيع الدولوميت كسارة الفك المتحرك

- الصين حجر آلة طحن الأفقي

- تركيب معدات خام الذهب المكثف

- مخطط تدفق الذهب طحن الكرة

- صور قطع غيار كسارات المطرقة

- اليابان معدات التعدين الصغيرة

- ندوة التعدين 2011

- خام المنغنيز تجهيز

- حجر سحق العملاء في الهند

- How To Start Stone Crusher Unit

- Unit Operation Mccabe Bs Hammer Mill Image

- Mobile Crushers All Over The World

- Ball Mill Grinding Operations

- Supplier Of Used Jute Mill Machinery In Dhaka

- Chromite Washing Plant Flow Chart

- Hot Selling Mechanical Can Crushing Crusher Price

- Coal Mines Companies In South Africa

- Rock Crushing Metal Ball

- Gap Vs Gape On Jaw Crusher

- Efficiency Rock Impact Crusher

- Beijin International Construction Machinery Exhibition

- Confidential Mining In South Africa

- Chrome Crushing Plant For Sale In Steelpoort

- Cobra Track Track Mounted Jaw Crusher

- Crushed Stone To Aggregate Machines Uk