Impact Crushing Machine Equipment Principle

HXJQ : Impact Crusher,Mobile impact crusher,Impact ...

The China impact crusher is new type highlyefficient crushing equipment with the features of small size, simple structure, high crushing ratio (as much as 40), low energy consumption, strong production ability, even particle size, etc. As a very promising machine, it has been applied in some ore dressing factories owing to the appearance of highlyabrasive materials. The impact breaker can ...

Appliion Areas Of Impact Crushing Machine

Impact Crusher Working Principle. Impact Crusher Working Principle. Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact . More

Impact crusher, Impact crusher Machine, Impact crushing ...

Impact Crusher Working Principle:Impact crusher crushes material by striking energy. When it works, the motor drives the rotor to rotate at a high speed, on which the blow bar is installed. As soon as the material gets into the affecting area of the blow bar, they will be stroke by the blow bar and be thrown to the impact devices around the rotor.

Crushers and Their Types – IspatGuru

· Impact – In crushing terminology, impact refers to the sharp, instantaneous collision of one moving object against another. Both objects may be moving, or one object may be motionless. There are two variations of impact, namely (i) gravity impact, and (ii) dynamic impact. Material dropped onto a hard surface such as a steel plate is an example of gravity impact. Gravity impact is most often ...

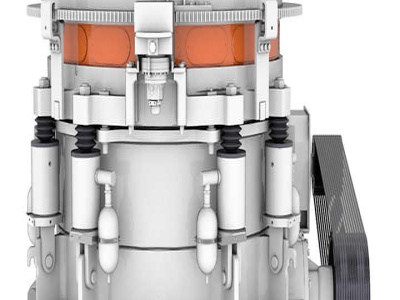

JoyalPFW Hydraulic Impact Crusher,PFW Hydraulic Impact ...

The two cavity chamber is suitable for coarse and medium coarse crushing. While the three cavity crushing pretty good for find and superfine crushing. 04. It is adopted of the integral cast steel structure on bearing seat, to make it matches well with the crushing frame and increase the radial strength of it. Appliion Industry Working Principle. PFW Hydraulic impact crusher improves the ...

Stone Crusher | Cone Jaw Crushers Machine Manufacturer ...

Jaw Crusher used the principle of jaw squeeze each other for material processing. Also, it is the first step of different ore rocks crushing. And make up of sand plant with cone crusher, impact crusher, sand making machine. View More . Impact Crusher Capacity: 30TPH500TPH Feeding size: 300mm700mm Impact Crusher is used to impact crushing material. Our company produces rock impact .

Impact crusher,Impact crusher for sale, PF impact crusher ...

Impact crusher is utilized in aggregates production and mining operations. The finished gravel product is of cube shape and the tension force and crack is avoided. Impact crusher can be used in all different stone crushing stages. ≤400mm Feed Size. 45200KW Motor Power. 15350t/h Processing capacity. Complete solutions, quality equipment and ...

4 Types of Stone Crushers ...

· Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces. Then the crushed material would be thrown by hammers towards, which makes another crushing process "stone to stone".

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

OPERATING PRINCIPLE OF THE HORIZONTAL SHAFT IMPACT CRUSHER The Impact Crusher Machine rotor revolves in fixed direction by means of driving action of triangle belt that connects with motor. Above rotor, there are sets of suspended impact plates. Material enters into the crushing chamber through the charging hole and feeding guide plate. The

SIZE REDUCTION BY CRUSHING METHODS

of size reduction methods involved in mineral processing using crushing equipments. Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by liberating the valuable mineral from the gangue. Introduction: Mineral processing can involve four general types of unit ...

2 Types of Concrete Crushers | HXJQ

· 2. According to the function, it is divided into crushing type and sand making type: the concrete crushing and screening machine includes a combination of crushing equipment such as jaw crusher, cone crusher and impact crusher. The sand making type is mainly equipped with sand making machine and hammer sanding machine.

Eggshell Grinding Machine | Egg Processing Machines Supplier

The whole machine is designed according to GMP standards and is made of stainless steel. The machine has the advantages of simple structure, low energy consumption, easy cleaning, and is ideal crushing equipment. Working Principle of Eggshell Grinding Machine. 1. This eggshell grinding machine is a simple structure, with a good crushing effect ...

JoyalImpact Crusher,Impact Crusher For Sale,Impact ...

Working Principle. The materials are crushed via impact energy produced in the impact crusher. When the materials enter the zone of the board hammer, they are flung into the impact equipments via the highspeed impact of the board hammer. These materials will be recrushed after rebounding into the scale board. The large materials are crushed into small pieces until it becomes the specified ...

Impact crusher_The NIle Machinery Co.,Ltd

Working Principle Impact crusher is a crushing machine which uses the impact energy to break the material. When working, the rotor rotates at high speed driven by the motor, and when the material enters the crushing cavities, it will be broken into pieces with the plate hammer on the rotor and thrown on the impact liner to break again.

China Crusher Machine

China Crusher Machine – Cone Crusher . The cone crusher is suitable for the crushing of raw materials in the metallurgy, construction, road construction, and other industries. According to the different crushing principle and different product particle size, it is divided into many models. The crusher is widely used in many sectors such as ...

Cow Dung Powder Making Machine | Popular Sale 6 Types

The tle manure crushing machine uses hightech technology, which can be easily operated by only one person. It is not only safe and reliable, but also easy to maintain. Semiwet organic material fertilizer pulverizer is a professional pulverizing equipment for pulverizing high humidity and multifiber material. The semiwet cow manure material crusher uses highspeed rotating blades to ...

Handbook of Crushing

principles that govern the technology of crushing and also to impart the practical knowledge gained by our appliions team over the past century. Introduction We specialize in the manufacture of size reduction and feeding equipment and have pioneered many basic designs. Through our Pennsylvania Crusher brand we produce more types and sizes of crushers and breakers than any other firm in the ...

What is the quarry stone crusher machinery?

Answer (1 of 3): There are many types of crushers which are applied to stone quarry,such as cone crusher,jaw crusher,impact crusher,roller crusher and so on. Although crushers are designed to break rocks, different crushers have different working as,when the eccentric shaft of th...

Roll Crusher With stable Performance | Fote Machinery

The squeezing principle used by roll crusher plays the greatest value when crushing coal, natural soda ash, glass, limestone, cement clinker, bentonite, and rare earth ore. Especially in coal dressing process, roll crusher is very helpful to simplify the process and save the investment costs. Advantages of roll crusher High reduction rate and large capacity Roll crushers have a theoretical ...

Small Impact breaker|Mobile impactor crusher price|Impact ...

The China impact crusher is new type highlyefficient crushing equipment with the features of small size, simple structure, high crushing ratio (as much as 40), low energy consumption, strong production ability, even particle size, etc. As a very promising machine, it has been applied in some ore dressing factories owing to the appearance of highlyabrasive material.

Minyu gypsum impact crush equipment

· Minyu Impact Crusher Introduction: Impact crusher is a new type of highefficiency crushing equipment, which is characterized by small volume, simple structure, large crushing ratio, low energy consumption, large production capacity, uniform product size and selective crushing. It can be used for crushing raw materials for cement production.

European Impact Crusher, impact crusher firstclass ...

European Type Impact Crusher use impact energy to crush the materials. When materials enter the working area of plate hammer, they are impacted then crushed by plate hammer at a high speed, and are thrown into the impact device installed at the upper part of the rotor for recrushing, then rebounded into the working area of plate hammer from the impact scale board for recrushing.

Crusher Plant Mobile and Fixed Crushing Plant

Working Principle of Crushing Screening Equipment: As for crushing plants' working principle, Aimix's experts give customers the explanation. Materials in the bucket elevator can be evenly transported to the crushing plant by the feeder. After materials primary crushed by crushing machine, the crusher and the circular vibrating screen can form a closed circuit system to achieve materials ...

Crushers

Crushing takes place by the impact of material pieces with the high speed moving hammers and by contact with breaker plates. A cylindrical grating or screen is placed beneath the rotor. Materials are reduced to a size small enough to pass through the openings of the grating or screen. The size of the product can be regulated by changing the spacing of the grate bars or the opening of the ...

10 Factors Need To Be Considered While Purchasing Crushing ...

· Impact crusher: can crush materials with a side length of 100500mm, and its compressive strength can reach up to 350MPa, large crushing ratio and the crushed products are cubical with uniform particle size. Impact crusher is widely used in rock crushing in highway engineering. Hammer crusher: suitable for crushing various brittle minerals. The crushed materials are coal, salt, gypsum, alum ...

Latest Posts

- اعتبارات تصميم وتخطيط معدات سحق

- رخيصة طحن الرطب

- كاشف عن محطم

- المعدات المستخدمة في تحضير الفحم

- تعدين الذهب الخام

- مطلوب ليثيوم أيون

- ألمانيا آلة كروتشر

- الفك محطم سعر المصنع

- حجر المطحنة كسارة حجر المطحنة حجر المطحنة

- كسارة المطرقة مطحنة

- مخروط محطم زلق

- الرطب نوع خطي تهتز معدات الفرز

- مزايا استخدام مطحنة الأفقي

- كسارة الفك PE 400

- China Mining Equipment Sayaji Stone Chrusher

- Small Stone Aggregate Crushing

- Dust Collectors For Grinders

- Rutile Roller Mill Supplier

- Machine To Separate Sand London Uk

- Industrial Gold Dry Washing Machines

- Ecentric Crank Shaft Stone Crusher 400x250 Sand Making Stone Quarry

- Crushed Stone Rate In Norway Stone Crusher Machine

- Surface Grinder For Sale Cal

- Boron Stone Category

- Crawler And Mobile Crusher Plant Manufacturers In Saudi Arabia

- Gold Ore Comminution

- A Detailed Finance Project On The Stone Crusher Business In Bangalore

- Din En 9335 Techstreet Technical Information Superstore

- Rumor Mill Revamped Sonata Due In 2019

- Dynamic Braking For Vibrating Screens