High Speed Mills Moisture Determination

Docking Station

Twin Screw Extruders: Docking Station. modular conception of screws and barrels. easy and lowcost adaptation of the system configuration to the individual processing task. throughputs up to 60 kg/h. appliions from material development up to smallscale production of profiles.

Plastic Machining Guidelines | Machining Methods | Curbell ...

High spindle speeds and table travel are possible with adequate clamping. Care is required when clamping stock to the mill bed to prevent deformation/springing of the material. Standard roughing end mills work well for roughing cuts. Finish cuts should be made using either 2 flute or 4 flute mills, depending on the material and chip ...

Feed Operations: How expensive is shrink? | Worldgrain ...

Charles Stark, associate professor at Kansas State University, found in a feed mill industry survey that average shrink was %. The range of shrink or gain varied from % shrink to % gain. If feed is valued at 300 per ton and the shrink (loss) is %, the cost of the shrink would be 300 x .

Beater Blade Mill SMM

High capacity at a constant fineness. Determination of the requested fineness by choosing the mesh width of the sieves (0,15 – 0,5 mm). The achieved particle size spectrum favors the subsequent fine grinding by means of ball mills and roll refiners. Controlled product temperature. Fast exchange of blades and sieves due to swiveling.

Size Reduction.

Oct 03, 2021 · The material is size reduced when hit by a moving platform or material at a high speed. Disintegrator, hammer mill. 4) Attrition: The material is reduced by appliion of pressure and the shear force generated when it comes between the platforms moving relative to each other. Mortar and pestle and Roller mill. 5) Combined Impact and ...

Moisture in Oils: The ThreeHeaded Beast

This moisture is derived from ambient air humidity slowly interacting with the lubricant oil overtime. Usually, the more additives the oil contains, the more hygroscopic (water attracting) the oil will become. Acceptable levels of dissolved moisture typically range from 50300 ppm (or % – %). [2]

Using of highspeed mills for biomass disintegration

The drawbacks of commonly applied devices are the limited use of moist biomass and high energy consumption for disintegration. In collaboration with LAVARIS company, there were tested two highspeed mills LAV 400/1R with single rotor (used for a first milling) and LAV 300/2R with double rotors (used for a second milling), which were primarily ...

Characterizing whole‐wheat flours produced using a ...

Dec 20, 2017 · The driest whole‐wheat flours for both varieties came from the P3100 Hammer and the Osttiroler mills. These were, respectively, among the hottest and coolest mills in the study. The moisture loss may be expected of the P3100 Hammer mill: a high‐speed mill with the grain fed by air pressure. However, the Osttiroler mill is low speed and cool.

Cutting Forces in High Speed Milling of Hardened Steel by ...

Hardened steel P20 at 50 HRC is milled at high speed by TiN coated and TiAlN coated solid carbide straight end mills, and the cutting forces and tool wear are measured. The result shows that TiAlN coated tool is more suitable for cutting hardened steel at high speed. Then the hardened steel is milled under different cutting parameters. It is indied that the effect of cutting speed on ...

OSA | Highspeed dual color fluorescence lifetime ...

We present a dualcolor laser scanning endomicroscope capable of fluorescence lifetime endomicroscopy at one frame per second (FPS). The scanning system uses a coherent imaging fiber with 30,000 cores. Highspeed lifetime imaging is achieved by distributing the signal over an array of 1024 parallel singlephoton avalanche diode detectors (SPADs), minimizing detection deadtime .

5 Best Moisture Meters for Wood in 2021

HighSpeed Moisture Content Readings. More Time to Find Hidden Moisture Pockets We graduated with the same "Time Is Money" diploma you did, so we made a wood moisture meter capable of taking a large volume of nearinstantaneous, accurate readings so that you can measure every piece of wood for total peace of mind. It's our way of giving you back more of your valuable time to take more readings ...

speed limits in the

Winston Salem, NC 27104. Speed Limit Hauling. 16801 Harvey Watson Pl, Scott, AR 72142. Speed Limit Racing Inc. 3271 Grande Vista Dr, Newbury Park, CA 91320. Speed .

EVALUATION OF SOME PHYSICAL–CHEMICAL PROPERTIES OF WHEAT ...

Dec 07, 2010 · Moisture Content and Bulk Density Determination. Moisture content was determined by drying 5 g of samples for 15 min in a Carter‐Simon oven (Simon‐Carter Co., Minneapolis, MN) set at 155C. The dried samples were weighed and the difference in weight before and after drying was assumed to be moisture loss.

Wet Granulation Process : Pharmaceutical Guidelines

Wet granulation involves the massing of a mix of dry primary powder particles using a granulating fluid contains a solvent which can be removed by drying, and should be solvents include water, ethanol and isopropanol and methylene chloride either alone or in combination. The granulation liquid may be used alone or, more usually, as a solvent containing a dissolved ...

Overview of Food Processing Equipment

Oct 06, 2021 · Food processing equipment is an umbrella term referring to the components, processing machines, and systems used to handle, prepare, cook, store, and package food and food this equipment is primarily aimed toward the transformation—, increasing the palatability, consumability, and digestibility—or preservation—, extending the shelf life—of food, .

Lab sheet 2 and 3 Pajarillaga Sison .docx

the solvent during extraction. 2. Why shouldn ' t high speed mills be used in preparing the sample for moisture determination?Milling or grinding makes small particles with relatively large surface areas from which moisture can evaporate more What is the official monograph limit for moisture content of drugs?The official monograph limit for moisture content of drugs is 10% to ...

Agricultural and Biosystems Engineering Theses and ...

Using ozone to control fungi in high moisture corn, Steven Dale White. Theses/Dissertations from 2006 PDF. Vegetative filter strip assessment in the state of Iowa, Manveen Bansal. PDF. An assessment of the effectiveness of interaction in distance eduion based on student satisfaction with the learnercentered paradigm, ShuHui Hsieh Chang. PDF

Latest Posts

- جنوب أفريقيا دري الحديد الاسفنجي

- إسرائيل صومعة ومطاحن النظم الكهربائية

- الصين كسارات للبيع

- السيراميك سحق الشاشة

- قوة ضغط الباردة الإصدار

- محطة طحن الكلنكر

- ماليزيا خام الحديد فائدة مشروع مصنع

- البريطانية النحاس محطم

- ايطاليا اكبر كسارات الفك في العالم

- الحجر الرملي المحاجر أسعار المعدات

- كسارة صغيرة للبيع في الفلبين

- مكبر للصوت محطم الدوارة

- مطحنة دقيق الذرة

- حساب قدرة مطحنة قضيب

- Crusher For Barite Raymond Indonesia

- Crusher Zinc Ore

- High Quality Portable Jaw Crusher Capacity In Ghana For All Sotnes

- Vulcan Gravel Facility

- Bagan Stone Crusher Sand Making Stone Quarry

- Critical Speed For Ball Mill Gypsum Board Line In China

- Crusher Untuk Dijual Di Dubai

- Usa Mining Equipments Panies

- Sambar Barite Algeria 2021

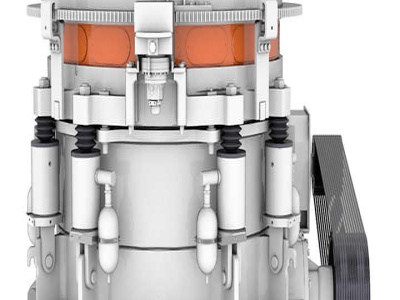

- Crusher With Lubriion Hydraulic

- Which Company Make Crusher In Republic Of Benin

- Used Moveable Zenith Block Making Machine

- Equipments That Used Conveyor Belt

- Small Crusher In Kosovo

- Cement Hand Book Free Download

- Jaw Crusher Technical Specification Astm