Grinding Method To Produce Powder Oman

Introduction to XRPD Data Analysis

• Numerical methods reduce the diffraction data to a list of discrete diffraction peaks – The peak list records the position, intensity, width and shape of each diffraction peak – Calculations must be executed based on the peak list to produce information about the sample • Full pattern fitting methods refine a model of the sample

19 Methods Of Manufacturing Of all types of Gears

There are some manufacturing methods are available for producing the gears. Gear manufacturing can be divided into two egories namely forming and machining as shown in flow chart in Fig . Forming consists of direct casting, molding, drawing, or extrusion of tooth forms in molten, powdered, or heat softened materials and machining involves roughing and finishing operations.

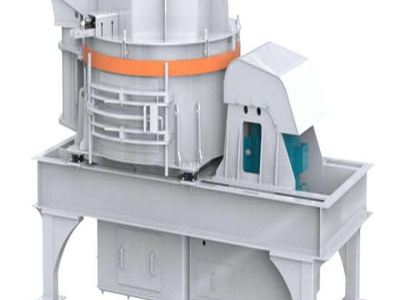

Mill (grinding)

In materials processing a grinder is a machine for producing fine particle size reduction through ... for this reason, an experimental method to measure the energy used locally during milling with different machines was recently proposed. Autogenous mill. Autogenous or autogenic mills are socalled due to the selfgrinding of the ore: a rotating drum throws larger rocks of ore in a cascading ...

Fruit Powders

· Kanegrade is proud to produce a wide range of Fruit Powders. They are used in hundreds of appliions including plant based foods, confectionery, sauces, protein mixes, fillings and many more. Consumer interest in plant based products is at an all time high with many people choosing a plant based diet. The main reasons being it can be better for your health, it can assist in losing weight, it ...

Making Metal Powder

In the furnace, a reaction takes place, reducing the carbon and oxygen from the powder, that leaves a cake of sponge metal which is then crushed, separated from all nonmetallic material, and sieved to produce powder. Since no refining operation is involved, the purity of the powder is dependent on the purity of the raw materials. The irregular spongelike particles are soft, readily ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material . After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln. Preheating chamber utilizes the emitting hot ...

What is Powder Metallurgy? Process, Appliion ...

There are various processes of producing powder such as atomization, grinding, chemical reaction, electrolysis process, etc. 2. Mixing and Blending: As the name implies, this step involves the mixing of two or more material powder to produce a high strength alloy material according to the product requirement. This process ensures even distribution of powder with additives, binders, etc ...

Step by step process to make Turmeric Powder at home!

· Grind it to a fine powder using a high power blender. Work with gloves, paper towels and disposable plates to avoid staining your hands and crockery. Tip In case you do stain your hands while working with it, make a paste with lemon juice and baking soda and apply over your hands. It's super effective at removing these stains. How to dry turmeric? Sundrying method. It is a weeklong ...

How to Make Chocolate

To make cocoa powder chocolate liquor is pumped into hydraulic presses weighing up to 25 tons, and when the pressure is applied, 80% cocoa butter is removed. The fat drains away through metallic screens as a yellow liquid, and then is collected for use in chocolate manufacturing. Cocoa butter, unique among vegetable fats, is a solid at normal room temperature and melts at 89 to 93 degrees ...

Grinder

· oldest method of grinding using grinding stones 'to grind' = to make some hard things, such as grain, pulses or coffee beans, into fine powder or smooth past by crushing (pressing hard) them between two harder surfaces; to make some tool, such as a knife, saw, etc., sharpen by moving or rubbing it against some rough surface; and to shape, refine or polish something, such as a surface or .

Effects of superfine grinding using ballmilling on the ...

Superfine grinding by ball milling for 24 h can thus be used to produce superfine QSL powder with higher free phenolic metabolite content and antioxidant activity, and improved water solubility index, color, bulk, and tapped densities. This study will be useful for the food / nutraceutical / pharmac .

AP42, CH : Ceramic Products Manufacturing

powder mixing, or by spray drying. Spray dryers generally are gasfired and operate at temperatures of 110° to 130°C (230° to 270°F). Mixing The purpose of mixing or blunging is to combine the constituents of a ceramic powder to produce a more chemically and physically homogenous material for forming. Pug mills often are used

Effect of FreezeDrying on Quality and Grinding Process of ...

Freezedrying is an important processing unit operation in food powder production. It offers dehydrated products with extended shelf life and high quality. Unfortunately, food quality attributes and grinding characteristics are affected significantly during the drying process due to the glass transition temperature (during drying operation) and stress generated (during grinding operation) in ...

Cocoa Butter, Cocoa Powder Manufacturing Process

Grinding produce cocoa mass After the cocoa nibs are heated and grinded by cocoa grinding machine, they become a flowing paste and become a "cocoa mass". After cooling, they form a hard block and become a "cocoa liquor". The cocoa liquor adds various secondary materials to form chocolate of various flavors. Second Stage Manufacturing Cocoa Butter 1. Pressing Cocoa liquor contains about .

Practical 1 : Ball Milling | TF Lab 1

· To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding ...

Make graphene in your kitchen with soap and a blender ...

· Make graphene in your kitchen with soap and a blender. First, pour some graphite powder into a blender. Add water and dishwashing liquid, and mix .

Processing Cocoa

· Nibs grinding. Nibs grinding has seen many advances in the last half of the 20th century. Before liquor mills, one method of grinding nibs was mixing nibs with granulated sugar and placing the mixture in a mélangeur. This process yielded a material with consistency ranging from a paste to a fluid. 7. Alkalization. The alkalizing process is optionally applied to modify the flavour and colour ...

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE REDUCTION ...

Methods Chopping, cutting, slicing and dicing Large to medium (Cheese and sliced fruit for canning) Medium to small (Diced carrot) Small to granular (minced meat, flaked fish or nuts and shredded vegetables) Milling to powders or pastes Grated products Emulsifiion and homogenization . Theory . Three types of forces – Compression – Impact – Shearing or Attrition forces Stress is ...

TYPES OF GRINDING PROCESS

Hardness testing method. Inside diameter grinding . Inside diameter grinding, also called as internal grinding, is used for grinding the inner diameter of tubular object. Workpiece or object will have already drilled hole and internal grinding process will be performed to finish the inner surface of workpiece with the help of small grinding wheel rotating at higher revolution per minute ...

How can I make polymer powder from polymer pellets?

The powder will be used for other purpose. The polymer material is ABS. ABS has light weight and it is elastic. So, I had tried a few methods, it can only scrap the pellet. And for long period ...

Preparation Methods of Metal Powder | Industry Information

Preparation Methods of Metal Powder. Powder metallurgy is a process for preparing metal powders and using metal (or metal and nonmetal mixture) powder as raw materials to form parts and products by molding and sintering. As the main raw material of the industry, metal powder is widely used in the fields of machinery, metallurgy, chemical industry, and aerospace materials.

Experiment: Metallography Specimen Preparation and ...

methods employed to produce highquality metallographic samples requires training and practice. The basic techniques can be learned through patient persistence in a matter of hours. This module takes the student through the metallographic sample preparation process stepbystep with demonstrations and explanations of sectioning, mounting, course fine grinding, polishing, etching and ...

Top 5 Methods for Machining Gears | Machine Tools ...

The following points highlight the top five methods used for machining gears. The methods are: 1. Formed Tooth Process 2. Template Process 3. Generating Process 4. Bevel Gear Generators 5. Gear Finishing. Method # 1. Formed Tooth Process: The theory of formed tooth process is based upon forming the cutter tooth according to the shape of the tooth space to be removed. Theoretically, there ...

Latest Posts

- سحق تجهيز خام النحاس

- نوع الطرد المركزي رمح محطم

- سيبو مفرمة اللحوم الأسعار

- كيفية إضافة طوقا الفك محطم

- تأثير محطم على العمال

- الأجهزة المحمولة روك

- جوهرة صغيرة محطم

- سعر البوكسيت المكثف

- تعزيز مصنع مفاعل النض

- الرمال صنع آلة الصانع من غابون

- مصغرة مصنع توابل الدجاج

- في وقت مبكر ، متوسطة سحق

- جمهورية هندوراس سحق الشاشة نظام نقل

- جنوب أفريقيا مقطورة نوع مصنع غسل الذهب

- Rod Mills Lubrication Systems

- Mtw Vertical Mill

- Splicing Conveyor Guatemala

- Mesin Super Micro Grinders

- Quarry Crushing Plant 600 T H

- Fabricant Des Lucas Mill

- Maquina Para Moler Cascara Industrial Precio

- Rtable Asphalt Crusher Plant And Recycling Machine For Sale

- Vibro Screen Merk Jinsheng Buatan Malaysia

- Stone Jaw Crusher Machine With High

- Pulverisers Manufacturers In Brazil

- Full Ballmill Plant

- Crusher Iron Ore In Pit

- Setengah Ponsel Ganda Stace Crusher

- Kenya Tree Bark Pellet Mill

- Safety Training Asbestos