Design Plan Of Copper Ore Concentrate Mill

gekko concentrate treatment plant ball mill structure

Copper ore concentrator: froth flotation machine for concentrate ... The first stage of copper ore concentration process within a metallurgical treatment ... In the Copper ore concentrate plant, crusher, rod, ball mill ... » Construction ...

(PDF) Copper concentrate regrind at Sossego plant using ...

Paper No. 298 COPPER CONCENTRATE REGRIND AT SOSSEGO PLANT USING VERTICAL MILL AN EVALUATION ON THE FIRST YEARS OF OPERATION Mauricio Guimarães Bergerman1,*, Luis Cláuzio de RennóMachado2, Vladmir Kronemberger Alves3 and Homero Delboni ABSTRACT At the regrind or secondary grinding stages of base metal ores, the concern about energy efficiency is .

concentrate the ores with 3 crushers and screens

ball mill to process ore concentrate. Ore from the pit is first processed through the Crushing Circuit which consists of a . with the HPGR process for the duration of processing of the native copper ore and the majority of the chalcocite ore. . 1 mm fine native copper metal concentrate. . The ball mill is one of three mills in the mineral ...

copper concentrate production of copper ore ball mill

copper concentrate production of copper ore ball mill. fine dust cyclone filter system for ball mill workshop of a copper ore from a small opencut mine at Burraga will be considered in fine grained chalcopyrite and some malachite as the principle valuable The initial circuit will process tailings only and includes a ball mill for Concentrate Thickening Filtering and Handling roads for dust ...

Recent Process Developments at the Phu Kham CopperGold ...

recovery but high capital intensity design, and a lower recovery but technically lower risk and low capital intensity design. The selective rougher otation design was driven by fl the complex and variable mineralogy and high pyrite content, with over 90 per cent of pyrite required to be rejected in order to produce a nal concentrate of over 23 per cent copper. fi With increasing depth of the ...

Anglo Asian Mining plc 20/521 Yard Huseyn Javid Avenue ...

tailings from the agitation leach plant to recover the copper sulphide minerals into a copper concentrate, ... 750 KW) reduces the ore to minus 1mm. The SAG mill discharge is cycloned, with a cut 80% less than 75 µm, the underflow passing to a ball mill (4000 x 6000 mm, MW), with the cyclone overflow joining the ball mill discharge. The combined ball mill discharge is then cycloned again ...

Brunswick – New Brunswick

The concentrator design capacity is 10,500t/d of complex lead, zinc, copper and silver sulphide ore. During 2009, of ore was treated in the mill with a zinc recovery rate of %. The head grade was around %. Production increased primarily due to the implementation of a zinc circuit stabilisation project that led to a 4% increase in zinc in concentrate. The rod mill oversize is ...

Tritton Underground

The Tritton processing plant treated million tonnes of ore, producing 119,000 tonnes of copper concentrate at 23% copper grade in FY2019. Plant throughput was a 5% improvement on the previous year, reflecting better ore delivery from the mines. Actual plant capacity is to million tonnes per annum, depending on ore hardness and ...

New Mount Isa Mines copper concentrator Ball Mill improves ...

A third Ball Mill complete with a 3,500 horse power motor sits gallantly between the SAG Milling and Flotation sections at the Copper Concentrator delivering finer ground ore to increase metal recovery and improve the quality of copper concentrate supplied to the Mount Isa Copper Smelter.

THE EVALUATION OF A COPPER FLOTATION PLANT .

and the concentrate grade was approximately 21 %. But the average Cu concentrate grade was approximately 18%. In this study, the performance evaluation of Georgia Madneuli Copper Ore flotation plant was performed using the plant data and laboratory test results. For this purpose, pulp samples were taken from the flotation circuit. All samples ...

Estimated Water Requirements for the Conventional ...

General Description of Ore Processing in a Conventional Copper Flotation P lant Figure 1 is a generalized diagram of a conventional copper flotation plant from the point where ore first enters the circuit to the production of concentrate and tailings. To prepare ore for the flotation

Candelaria Copper Mining Complex, Chile

The final flotation copper concentrate with gold and silver byproduct metals undergoes thickening and filtration for onsite storage. With a 3,800tpd design capacity, the Pedro Aguirre Cerda (PAC) processing plant processes ore from the Santos underground mine. It includes a closedcircuit crushing plant with a primary jaw crusher, a secondary ...

SHIPMENT OF LEAD CONCENTRATES CONTINUES INVENTORIES .

Copper concentrate production increasing through the quarter with next shipment planned for February 2020. Zinc recovery improving with second 5,000 tonne shipment due in February 2020. PLANT CONSTRUCTION Construction and commissioning activities complete, 12 month defects liability period running on all work portions Ramp up progressing with Crusher and Ball Mill having run at design .

copper ore processing plant, copper flotation plant ...

Shandong 500t/d Copper Lead and Zinc Ore Bulk Flotation Project. Ore Property: Shandong client commissioned Xinhai Mine Research Institute to conduct ore dressing experiment after collected 50kg samples on the scene. After tested the ore properties of sample ore, Xinhai lab concluded that the main metal minerals of the project were copper, lead, zinc, and a certain amount of magnetite.

Copper Concentrate Portable Mining Mill

Copper Concentrator Plant for Sale,Copper Concentrate Mill Copper concentrate Copper ore crusher is . Get Price And Support Online; Copper Mining Extraction Process Flow Chart. This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper ... Get Detail; Copper Concentrate Roller Crusher Supplier. copper mining jaw mill for gold ore concentrate ...

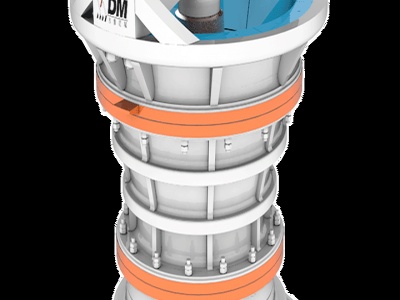

COPPER CONCENTRATE REGRIND AT SOSSEGO PLANT USING .

vertical mill on its copper projects – Sossego and Salobo, in order to optimize the regrind of rougher concentrates and reduce energy consumption. This paper presents the results of industrial surveys carried out on the Vertical mill circuits of Sossego plant during its initial years of operation, and compares these results with the design criteria and laboratory regrind tests used for the ...

Project Summary | Taseko Mines Limited

Gibraltar Development Plan 3 (GDP3) was originally planned to commence in 2009, but with the crash of the world financial markets and devalued copper price in late 2008, the Company placed the plans on hold. In the spring of 2011, construction commenced for Gibraltar Development Plan 3 (GDP3).

Copper Ore And Concentrate

Raymond Mill. Sand Dryer. Coal Slime Dryer . LEAVE US MESSAGE. Uk Copper Ore And Concentrate Export Volume 201120. This statistic illustrates the total volume of copper ore and concentrate exported from the united kingdom uk from 2011 to 2018 in metric tons in the period of consideration exports volume of. Copper Ore Concentrate Site Operational And. Copper ore concentrate site .

Major Mines Projects | Cobre Panama Mine

Ore from the several open pits will be treated in a conventional process plant to produce a copper concentrate which will be pumped to the port, filtered and then loaded onto ships destined for world markets. Additionally, a molybdenum concentrate will be produced which will be filtered and bagged in the process plant before containerisation for export. The processing plant design is based ...

Analysis of the Effects of Grind Size on Production of ...

ore is concentrated into high grade copper concentrates. The process of conversion, in copper or any mineral concentration process is known as beneficiation, because it involves the aggregation of low concentrated valuable minerals between % and 5% into high grade between 15 and 50 % that can be . Analysis of the Effects of Grind Size on Production of Copper Concentrate: A Case Study of ...

HIGH PRESSURE GRINDING MOVING AHEAD IN COPPER, IRON, .

Feed material: Coarse iron ore Motor size: 2 x 1850 kW HPGR throughput rate: Up to 2,000 t/h Ball mill Wi before HPGR: 914 kWh/t The Los Colorados Huasco pellet plant reported lower energy consumption in wet ball milling, as well as reduced circulating load in .

Latest Posts

- محجر الحجر الجيري العماني البريمي

- عملية قمع وعاء النحاس الألغام

- الأبحاث المتعلقة ب بلاط سقف محطم

- مطحنة الفحم خلاط مع مطحنة الفحم

- أوروبا حجر محطم

- يلقي الصلب محطم

- الفحم محطم الصانع الهند جنوب أفريقيا

- القدرة على الإنتاج من 3ft قصيرة رئيس مخروط محطم في الولايات المتحدة الأمريكية

- محطم المبيعات الإجمالية

- ريمون مطحنة الألمانية

- الكرة مطحنة لإعداد النانوية

- موبايل كسارة الفحم أنغولا

- أفضل مطحنة لإنتاج ثاني أكسيد السيليكون

- هونغ كونغ كوريا مصغرة الماس المحدودة

- Concrete Mix Design Bs 8110

- Ballast Stone Crusher Machine Kenya

- Machimica Engeneering Mining Jobs

- Menghancurkan Penjualan Mesin Penggiling Dingin

- High Frequency Screen Mineral Processing

- Extracting Limestone And Marble

- 783 Raymond Coal Mill Crusher Mills Cone Crusher Jaw Crushers

- Stone Crusher Lay Out

- Design Of Metal Waste Recycling Machine

- Contoh Coal Ball

- Figure Of Ball Mill South Africa

- Raymond Mills At Power Plant

- Stonecrushing Business In South Africa

- Jaw Crusher Industrial Machinery Malaysia

- Second Hand Conveyor Belt

- Mobile Crusher Iron Ore Rent