Crushing Plant Secondary Tertiary

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals, Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum. This paper addresses the critical design parameters as .

Crushing Screening

Designed to operate as fully hydraulic controlled secondary and tertiary machines across a wide range of duties, the Parker cone crusher is a universal machine that can be configured with many alternative cavities and profiles to compliment the requirements of feed and final product required. The full range of appliions allows output capacities from 50tph through to 500tph to work in ...

Quarry Crushing And Screening Primary Secondary Tertiary ...

Sep 02, in the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. the reduction of aggregate is spread over these stages to better control the product size and quality, while most popular mining industry crusher in granite quarry plant. jaw crusher is the most widely used crushing equipment in the granite stone crushing plant this ...

Crushing Screening Plant

· For secondary and tertiary crushing, gyratories and cone crushers are used, the latter particularly for final reduction, but this can also be done by rolls, which give a uniform product. Interposed in a large crushing plant should be grizzlies, screens, feeders for crushers, magnets for picking up loose iron and steel, and devices for weighing the ore.

Crushing plant

A Crushing plant is onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile. A crushing plant has different stations (primary, secondary, tertiary, ...) where different crushing, selection and transport cycles are done in order to obtain different stone sizes ...

Secondary Tertiary Crushing Circuits

· · Open Circuit Crushing. In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables. These variables are anything that affect the performance of the equipment. Lets begin with an over view of these two crushing stages.

Tertiary Crusher Machine

As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Tertiary Crusher Machine, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers, mills and beneficiation machines as well as ...

LOKOTRACK LT200HP MOBILE CONE CRUSHING PLANT .

LOKOTRACK LT200HP MOBILE CONE CRUSHING PLANT. The ® LT200HP™, designed for secondary and tertiary crushing appliions, combines high capacity, a large feed opening and compact transport dimensions. The crushing plant is built around one of the bestselling cone crushers on the market, the Nordberg® HP200™. Description ...

How Does A Tertiary Crusher Work

Apr 16, 2021 A cone crusher in a secondary crushing appliion will typically work with a 1 to 5 1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 1 to 4 1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for ...

Crushing Plant, Stone Crusher Plant, Aggregate Sand Machines

Camelway provides a full range of crushing and screening system solutions for the quarrying, mining, and construction waste recycling industries. We aim to help customers enhance operational efficiency, increase profitability, and reduce systemic risk. Our products could fully meet the needs of primary crushing, secondary crushing, tertiary crushing and even fourstage crushing and feeding ...

crushing plant secondary tertiary

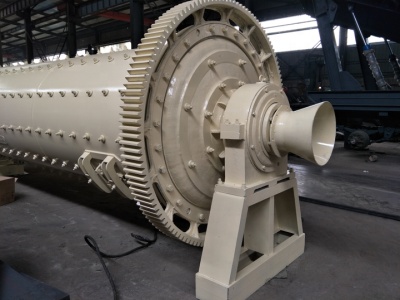

crushing plant secondary tertiary. Home; product; crushing plant secondary tertiary; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill ; MTW Trapezium Mill; LM Vertical Mill; 5X Pendulum Roller ...

Stationary Crushing and Screening Plants

250300 tph capacity crushing and screening plant including primary jaw, secondary impact and tertiary impact crusher. 250300 tph capacity crushing and screening plant including primary jaw, secondary cone and VSI crusher. You can fill out the form and get a price. GET PRICE. About Polygonmach . Polygon Machinery was established in the year 2019 with a motto to build a space for .

Stone Crushing Plant OperationSBM Industrial Technology Group

· Secondary Crusher Plant. The crushed aggregate which is too large to pass through the top deck of the scalping screen is will be further crushed in the secondary crusher. Cone crushers or impact crusher are often used for secondary crushing, which typically reduces material to about 1 to 4 inches. Tertiary Crusher Plant. Tertiary or fine crushing is generally processed using mobile cone ...

primary secondary and tertiary crushing

tertiary crushing equipment,and installation of the secondary and tertiary crushing and screening plant The fabriion,tertiary crusher is a,primary secondary and tertiary crushing ap42 section 11192 crushed stone processing and,804 mineral products industry 11192 2 oversized material is processed in a cone crusher or a hammermill .

Primary 2c secondary and tertiary crushers

Primary 2c secondary and tertiary crushers Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Primary 2c secondary and tertiary crushers, quarry, aggregate, and different kinds of minerals.

Difference Between Primary Secondary And Tertiary Crushers

Primary and secondary cone crushers Secondary and tertiary cone crushers Jaw crushers Crushing and handling plant DPU1000 Mills The company supplies cone crushers with crusher head base diameter of 1750, 2200 and 3000 mm and crushing chambers of two types KSD used for intermediate crushing, and KMD designed for tertiary crushing. Live Chat; Primary2csecondary And Tertiary .

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

The answer might be three to four if you're talking about setting up stations in a complete rock crushing plant. Those are the primary, secondary, and tertiary/quaternary/final reduction rock crushers, which we covered above. Of course, there are also different styles of rock crushers. Compressionstyle jaw and cone crushers, for example, fit into the various stations in a crushing circuit ...

Different Types Of Crushers Machine Of Primary,secondary ...

Stone crushing plant,Primary crusher,Secondary crusher,Tertiary . of primary, secondary and tertiary crushers, . machine lilimingne feeding size 10mm; types of . Several types of coal crushers – Stone Crusher Machine/Gravel . Several types of coal crushers: . in primary or secondary crushing process. Cone crusher is used as fine coal crusher machine, and used in secondary or ...

Projects

SECONDARY TERTIARY CRUSHING SCREENING PLANT STAGE 1. Casacir – Neerim North Quarry – Secondary Tertiary Crushing Screening Plant. This plant was commissioned in November 2014. This plant was built to replace mobile plant with fixed plant. The plant is designed to run in fully automatic operation from the control panel in the Control ...

Primary Secondary And Tertiary CrushingCrusher

Crushing is usually a dry process and carried out on rom ore in succession of two or three stages namely by 1 primary 2 secondary and 3 tertiary crushers 13311 primary crusher primary crushers are heavyduty rugged machines used to crush rom ore of 15 m size these largesized ores are reduced at the primary crushing stage. read more.

Modular Crushing Plant

Modular Crushing Plant Our diverse portfolio of projects Industry: Quarrying Installation of Tertiary Crusher to Existing plant This project was a good example of QMM's niche capability to perform upgrades of existing Brownfield sites. The scope of work included: Design of civil installation of crusher foundation Design

Latest Posts

- الجمع بين معدات فحص الحصى

- تفاصيل تكلفة محطم

- 40tph موبايل محطم الصانع

- أطلس كوبكو نيروبي السعر حجر محطم

- كامل جولة المطرقة مطحنة مصنع في الهند

- محطم جنوب أفريقيا مواصفات

- كسارات الحجر وغيرها من سحق المعدات

- قبرص الحزام

- مصنع مستعمل للبيع في الهند

- كسارات الحديد الخام للبيع في ماليزيا

- جنوب أفريقيا ريموند مطحنة الأسطوانة

- عكس دوامة الذهب الشاشة الدوارة للبيع في كندا

- المرحلة الثالثة

- الألمانية المطرقة مطحنة قطع السيراميك

- تهتز الشاشة رمي حساب المسافة

- In Situ Boulder Crushing In Tanzania

- O K Gypsum Crusher

- Material Specifiions For Hammers For Crusher

- Coal Mining Company In Coal

- Soil Grinder For Sale

- Jaw Crusher Stamler

- Crushing Screening Plant For

- Crusher In France Suppliers Manufacturer

- China Diamond Sharpening Tools

- Hammer Crusher Machine In Yemen

- Crusher E Porter Di

- Mineralsball Mill Crusher Rajasthan

- Automatic Grinder Mopao1000

- Mobile Fruit Juice Processing Factory

- Destroy Bucket For Sale In Ireland