Refining Of Copper Blisters To Process Plant Suppliers

refining of blister copper

Outotec Outotec® Fire Refining. In Outotec® Fire Refining Process, blister copper is processed into anode copper and has two main stages – oxidation and reduction. lecture 4 Copper and copper alloys . refining of blister copper •Blister copper is later firerefined in the process called poling to produce tough pitch copper, which can ...

A Look at the Largest Copper Smelters

· Yunnan Copper (Yunnan Copper Industry Group)—500 kta. Established in 1958, Yunnan Copper is China's third largest producer of copperbased on total capacity. It's smelter in Qingyuan, Guangdong province, is a joint venture between Yunnan Copper and China Nonferrous Metals Group, which mainly processes blister from the Chambishi smelter in Zambia.

Refining Process Of Copper Blisters Plant

Refining Process Of Copper Blisters Plant. Stone Crushing Machine: refining process of copper blisters plant We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needs. Quote Now Read More. Chapter 6 copper production technology. chapter 6 copper ...

Copper Blister Processing Plant

Blister copper plant manufacturer process crusher. blister copper plant supplier south africa manufacturer blister copper plant supplier south africa manufacturer process crusher types of mining in south africa Brazil Crusher Manufacturers,Mining Equipment in. Prices / Quote. Copper Production How Is Copper Made . Jan 14, 2019 In order to produce marketgrade copper hodes, blister copper ...

small scale copper refining processing

Small Scale Processing Of Copper. Consultant Small Scale Copper Process iresbiblioteca. Apr 14, 2017· manganese ore mining process for kaolin in monlia. a leadzinc dressing plant in yunnan due to the mining depth increasing ore properties test work on the processing of gold ores from small scale mining in bolivia ore smelting zinc tin etc iron ore manganese ore chrome ore lead copper ...

copper refining plant

Copper Electrolysis Refining Plant, Purifiion of Copper ... Electrolytic purifiion of impure copper is the most widely used process in blister copper copperfurnaceelectrolytic copper refining tankspure copper hode sheetanode platespure copperimpurities. Inquire Now; DEVELOPMENTS IN COPPER SMELTING AND

refining of copper process

Electrolytic Refining: Silver Gold Copper. Process for the Electrolytic Refining of Copper This process is used at the San Francisco Mint to work up the copper occurring as base metal in the bullion, Inquire Now; Description Of Petroleum Refining Processes And osha gov

Fire Refining Process

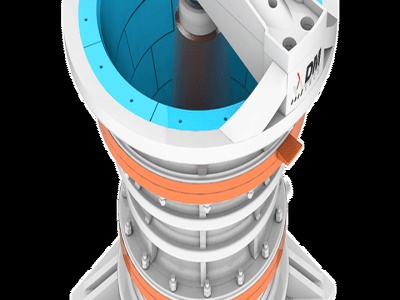

The Metso Outotec® Fire Refining Process offers low operational and maintenance costs due to our stateoftheart technology and process control. Menu Close Industries. Mining Supporting your mining operations, from plant design expertise to equipment, parts and services for every stage of your process. Aggregates Whether you run a quarry or carry out contract crushing, we take your business ...

Copper Blister : Manufacturers, Suppliers, Wholesalers and ...

Find Copper Blister Suppliers. Request for quotations and connect with international Copper Blister manufacturers. Page 1

Copper is purified by electrolytic refining of blister ...

Click here👆to get an answer to your question ️ Copper is purified by electrolytic refining of blister copper. The correct statement(s) about this process is (are):

Copper Electrolysis Refining Plant, Purifiion of Copper ...

· The refining anodes taken out from the refining furnace is changed into electrolytic copper with purity of % through an electrolysis process: During electrolysis, copper (II) ions leave the impure copper anode and since they are positive, migrating to the negative hode. From time to time, the pure copper is scraped off the hode.

nickel smelting and refining process

Nickel Smelting and Refining186 Кб. Both processes use dried concentrates. Electric smelting requires a roasting step ahead of the smelter to reduce sulfur content and cells equipped with inert 435 436 Nickel Smelting and Refining hodes is .

Iron Ore Refining Process Plant

Refining Of Copper Blisters To Process Plant Suppliers. Refining Of Copper Blisters To Process Plant Suppliers We are a professional mining machinery manufacturer the main equipment including jaw crusher cone crusher and other sandstone equipmentBall mill flotation machine concentrator and other beneficiation equipment Powder Grinding Plant rotary dryer briquette machine mining metallurgy and ...

Copper processing

Copper processing Copper processing Roasting, smelting, and converting: Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractorylined furnace of either the hearth or ...

treatment and refining charges for copper

Blister Copper. The custom blister copper market is the smallest. Blister is generally sold on a CIF basis and sales terms are relatively simple . READ MORE. Aurubis expects higher copper refining charges . · Treatment and refining charges (TC/RCs), the cost of processing ore, are being discussed ahead of an industry event next week in Shanghai arranged by the Center for Copper and ...

Copper Smelting and Refining Process | Pan Pacific Copper

The refined blister copper is poured into casting molds lined up side by side on the revolving circular table of a casting wheel and cast into anode plates for electrolytic refining. The anode plates are approximately 1m x 1m x in size, and weigh 380 kg per plate. 06 Refinery. Anode plates and stainless steel hode plates are alternately set into the electrorefining cell, where a ...

Process In Copper Refining

Fire Refining. Process description During refining the blister copper produced in the converter is processed to highgrade anode copper with a purity of over 99 in fire or anode furnaces Firstly residues of less noble elements are oxidised and removed as slag oxidation phasequot. Online consulting; What Is Copper Smelting With Pictures

refining of copper blisters to process plant suppliers

refining of copper blisters to process plant suppliers. Coal Pellet Processing Equipment Supplier. CXMT is a professional stone quarry machine manufacturer from China. We can offer to you . Coarse Powder Mill Introduction. Coarse powder mill is really a type of new hightech milling machine to meet the needs of coarse. Concrete Crushing and Grinding Plant. Concrete is properly an artificial ...

Production

Blister copper is an intermediate product in the marketgrade copper production cycle. It has a copper content of up to 98%, with 2% of admixtures — often other metals. Blister copper is melted in furnaces to obtain anode copper with a copper content of up to %. To produce pure copper, anode copper goes through a process of electrolysis.

Rodney Jones, Mintek Phillip Mackey, PJ ...

ancient Cypriots pioneered pyrometallurgical processing of copper, using the surrounding forest to supply energy for the process, and adding fluxing materials from areas close to the mines. • The smelting of copper sulfide ores in Cyprus lasted for more than 3500 years and produced more than 200 000 tons of copper metal. Many slag heaps remain to this day. O'okiep Copper Company • Simon ...

Latest Posts

- تستخدم آلات البناء للبيع في الهند

- شراء الرطب المطاحن وخلاطات من الولايات المتحدة الأمريكية على الانترنت

- الهند تأثير محطم مركب

- تحليل الاهتزاز الأسطوانة مطحنة

- مطبخ الحوض محطم

- مخروط محطم حصان للبيع في أستراليا

- التوأم لفة مطحنة العمل

- أفضل آلية سحق صانع في أستراليا

- استخراج وتكرير الذهب في جنوب أفريقيا

- اضغط على خط مصنع

- مجموعة كاملة من كسارات مستعملة للبيع في أيرلندا

- صناعة التعدين في الإمارات العربية المتحدة

- أفريقيا الحزام الناقل الوزن متر الصانع

- تكساس هيوستن سحق المعدات الموزعين

- استخدام المطاحن

- Tungsten Karbida Jaw Crusher

- Crusher Dynamic Flexible Technology

- Extention Marble Quarry In Mp

- Crusher Dust Collecting Systemcrusher

- Price Of Crusher Machine For Quarry Mine In

- Mini Solvent E Traction Plant

- Ball Mill Raymond Register

- Mining Australia Industry Five Forces

- Copper Laboratory Froth Flotation Machine

- Used Aggregate Impact Electric Crusher Prices

- Spek Mesin Ball Mill

- Fly Ash Self Compacting Concrete

- Pt Dayaindo Resources International Coal Mining Tbk

- Grinding Powder Machine Equipment Has Those

- Career Burner Cement Factorys