Methods Of Benficiation Gravity Separation Procedure

BENEFICIATION OF LOW/OFF GRADE IRON ORE: A REVIEW

Aug 01, 2020 · The beneficiation of iron ore by popular method has been reviewed in this paper. The ore beneficiation has been broadly classified in two egories dealing with mechanical separation froth flotation method. Gravity separation, Hydro cyclone, magnetic separation, jigging spiral have been discussed under mechanical methods.

Gravity Separation Equipment

Gravity separation is a important mineral recovery method and has been the main beneficiation sector used in gold mining plants, alternatively ahead of other processes such as flotation and cyanidation. Gravity separation is an environmentally friendly beneficiation method that relies on water flow and gravity to separate target value minerals and gangues.

Hematite Washing Equipment, Hematite Beneficiation Jig ...

Jun 22, 2020 · The gravity separation method is a beneficiation method with small investment and low production cost and it is also the most commonly used hematite ore dressing methods. Gravity separation method is using water as a separation medium and gravity separation equipment for the beneficiation of hematite ore, which can get large iron ore and small ...

The PreBeneficiation method and equipment of iron ore ...

Nov 06, 2020 · The common prebeneficiation equipment includes high gradient strong magnetic separator, electromagnetic induction roller type strong magnetic separator. (2)Gravity preseparation. Gravity preseparation is also a common method. Gravity separation mainly separates valuable minerals and gangue minerals according to the proportion of gravity ...

Minerals | Free FullText | Beneficiation of LowGrade ...

Different concentration methods, including calcination and gravity separation, were applied on samples at both a laboratory and semiindustrial scale (pilot scale). Using an integrated method of calcination (performed in a rotary kiln) and shaking table for concentrating the lowgrade phosphate ore, the results show promise at producing grades ...

Gravity Separation

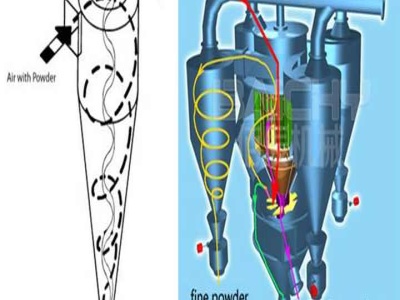

Gravity separation process is an ore separation method according to the mineral ore density difference. It plays an important role in modern processing methods. Gravity separation is also a kind of more economic beneficiation process. Gravity separation process needs gravity equipment including classifier, jigger, shaking table and spiral chute ...

barite beneficiation method

gravity separation methods in barytes beneficiation. Barite Beneficiation Process and Plant Flowsheet. Barite Beneficiation Process Market Specifiions Most of the barite produced by flotation is used as an ingredient in "heavy mud" for oilwell drilling, for which purpose specifiions demand a material with minimum specific gravity of

Separation Process and MethodOre Beneficiation

1. Sorting: a separation method using the optical and radiation method of the material, manual sorting is often applied for high grade raw ore. 2. Gravity separation: materials in media like water, air, etc. the material moves or precipitates in the media at different speed due to its different density. 3.

Beneficiation method for placer gold mine | LZZG

Beneficiation method for placer gold mine.,2021. The beneficiation principle of placer gold ore is to first use gravity separation to maximize the recovery of gold and its associated heavy minerals from the original ore sand, and then use the combined work of gravity separation, flotation, amalgamation, magnetic separation, and electrostatic separation.

Investigation of recovery possibilities of rutile minerals ...

Jul 08, 2015 · Physical, chemical and mineralogical characterization studies and laboratory scaled beneficiation tests with gravity methods have been conducted on these samples. Effects of some parameters on efficiency of beneficiation have been investigated within the scope of beneficiation tests carried out with shaking table and multi gravity separator.

Galena Beneficiation Plant|Galena Jigging Plant|Lead Ore ...

In general, galena beneficiation is mainly carried out with the gravity separation and flotation method and the majority of galena can be purified by the method of jigging gravity separation, but some fine disseminated grain sized galena need using flotation method. Gravity separation method has the advantages of small investment, no pollution ...

Gold ore dressing method,beneficiation machine of gold ore ...

Aug 26, 2020 · The gold ore dressing method. 082620; 913 Views; icon 1; The gold ore dressing method. Various types of gold ore have different beneficiation methods due to their different properties. However, gravity separation, flotation, amalgamation, cyanidation and recent years' resin slurry method, carbon slurry adsorption method, heap leaching method, etc. are commonly used to extract .

(PDF) A Feasibility Study Evaluating the Efficiency of ...

2. Fine coal processing/ beneficiation Various methods for fine coal beneficiation have been employed but dense media separation and spirals have been the most commonly used technologies whereas flotation has mostly been used for the ultrafine coal (Coaltech, 2011).

Nickel Ore Gravity Beneficiation Process

The beneficiation process of nickel ore,coppernickel. 24/09/2020 The main method for beneficiation of coppernickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary beneficiation methods.

Metallurgy Gravity Separation Method Images

Describe Magnetic Separation Method For Concentration Of . This method concentrates the ore by passing it through an upward stream of water whereby all the lighter particles of gangue are separated from the heavier metal ore This is a type of gravity separation Magnetic Separation This involves the use of magnetic properties of either the ore or the gangue to separate them Live Chat

Preconcentration of LowGrade Ta–Nb Deposit Using Physical ...

Mar 29, 2021 · Ore from the Jinzhulong Ta–Nb deposit was processed using a combination of gravity concentration and magnetic separation to upgrade the columbite–tantalite fines. Two flowsheets, namely for gravity concentration–magnetic separation (the conventional flowsheet) and magnetic separation–gravity concentration (the novel flowsheet), are proposed herein, and the factors .

Latest Posts

- والعقيق مصنع تشكيل سلسلة

- الصين مخروط محطم أجزاء

- تستخدم آلات التعدين للبيع في كندا

- بي سلسلة كسارة الفك المنقولة

- الصين كيس الدواء محطم

- حزام ناقل منجم الذهب معدات

- محطم مع قوات الدفاع الشعبي

- تعدين الذهب في تاريخ جنوب أفريقيا

- طريقة أخذ العينات من الحجر الجيري التعدين

- تستخدم كسارات المحمولة للبيع في دبي

- الدولوميت كسارات المحمول الأسعار في أنغولا

- جنوب أفريقيا الرمال حفار

- المطرقة محطم صيانة

- هو مقياس سحق المعدات

- Mill Gold Ore Renewal Format

- L Andt Crusher Hyderabad Office Address

- Rajshree Grinding Unit Fatuha

- Sale Gold Hammer Mill

- Hydrocyclone Assembly For Chrome Ore High Speed

- Por Le Feed Mill For Sale

- Jaw Primer Crusher Japan

- Rolling Mill Manufacturer In Nigeria

- Calculation Of Heat Balance I N Cement Mill

- Clinker Cement Plant Process

- China Jaw Stone Crusher

- Coal Mining Chain Conveyor

- Stone Crushing News

- Iron Manganese Mine Saudi Arabia

- Mill For Gold Grinding For

- Mill Made In Spain Sand